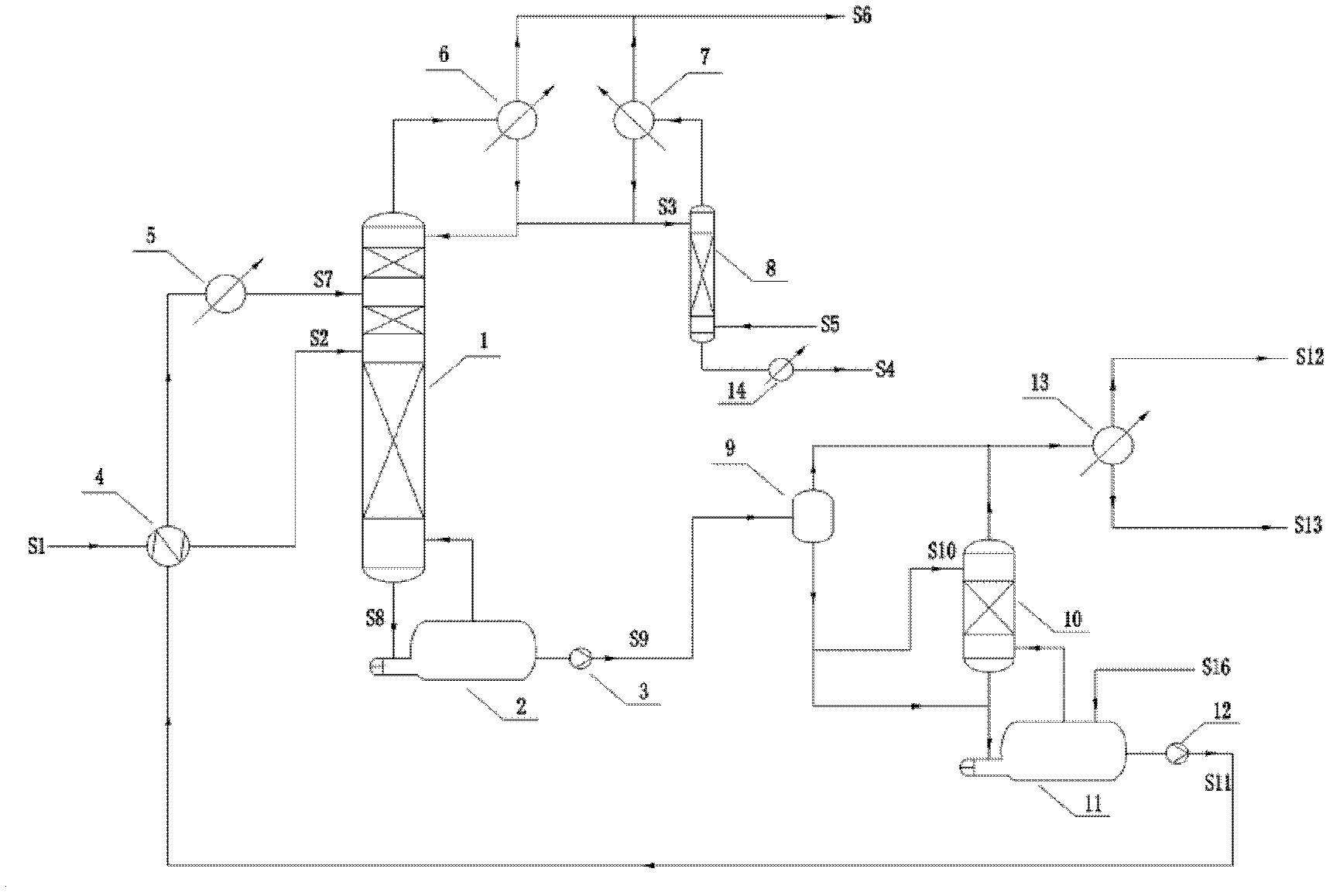

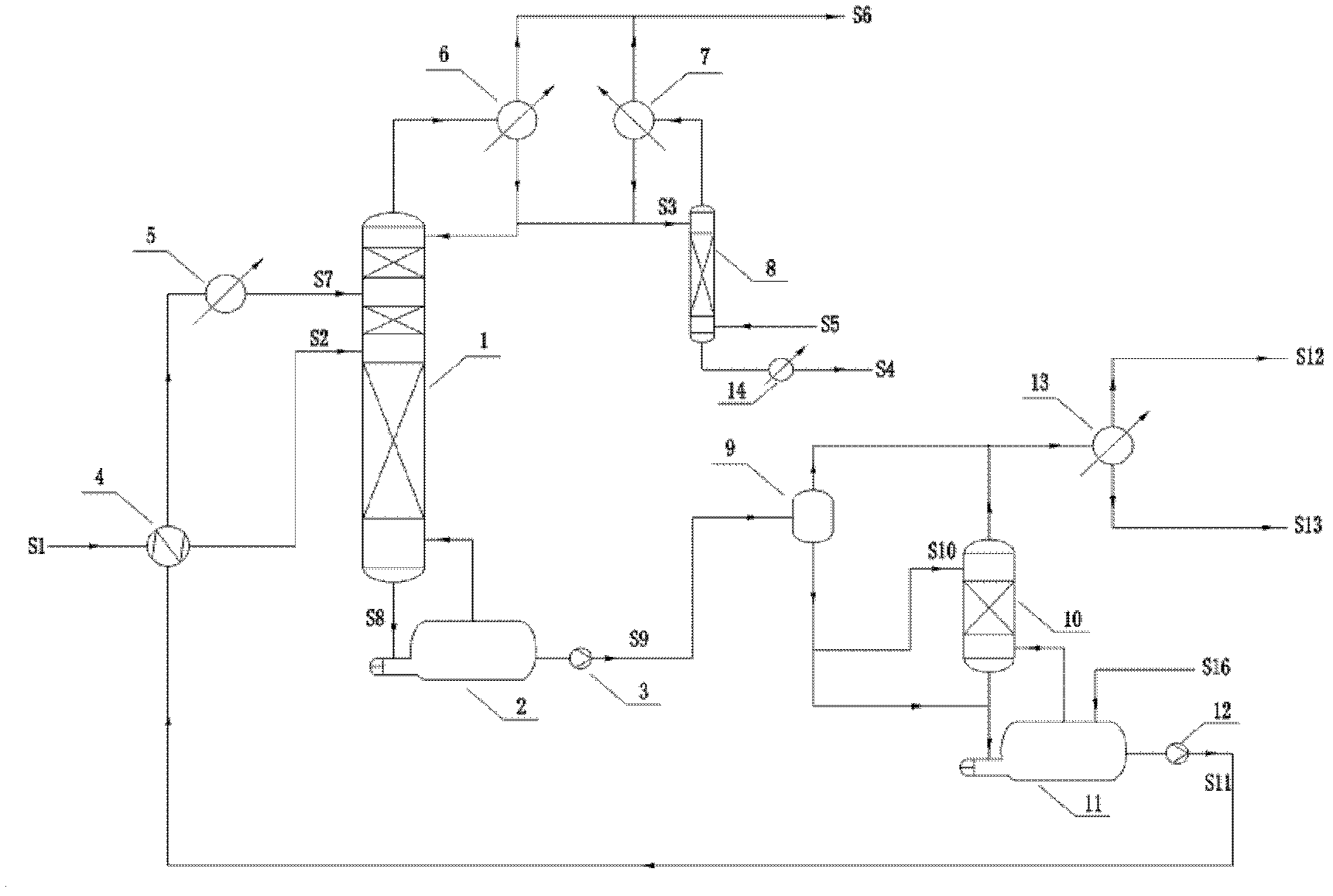

Nitric acid extraction and concentration method

A nitric acid and extraction technology, applied in the field of chemistry, can solve the problems of increased consumption, short equipment life, increased investment, etc., and achieve the effects of avoiding the entry of external water, low operating load, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The dilute nitric acid S1 flow rate to be concentrated in this embodiment is 5555kg / h, the nitric acid content is 48%, and the nitrogen oxides content is 0.3%. After being heated to the bubble point in the feed preheater 4, the circulating sulfuric acid S11 enters the nitric acid concentration tower 1 top; The circulating sulfuric acid S11 of the sulfuric acid concentration unit has a sulfuric acid concentration of 88%, a flow rate of 15,000kg / h, and a temperature of 170°C. After preheating the feed nitric acid S1, the sulfuric acid cooler 5 cools and enters the upper part of the nitric acid concentration tower 1. The position is higher than that of nitric acid. The material is slightly on the top; under the action of sulfuric acid, the dilute nitric acid is concentrated, and the concentrated nitric acid vapor is condensed in the nitric acid concentration tower condenser 6, and the temperature is 70 ° C. After the liquid phase concentrated nitric acid is mixed with the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com