Zero-emission production process of electrolytic manganese wastewater

A production process and zero-emission technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as environmental hazards, waste of valuable resources, and environmental pollution, and achieve Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with embodiment.

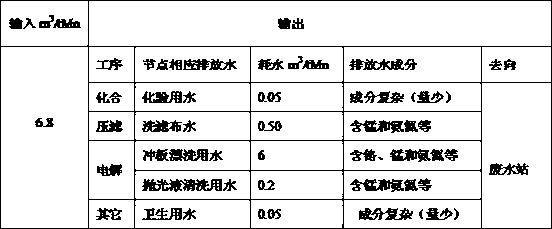

[0030] This embodiment includes grinding, pulping, compounding, transfer, pressure filtration, electrolysis, passivation, and rinsing processes, and is characterized in that the following steps are also provided:

[0031] (1) Recycling of filter cloth washing water: After the filter cloth washing water generated in the filter press process is filtered through the pipeline filter, it is returned to the cloth washing water pool for recycling;

[0032] When the free manganese concentration of the filter cloth washing water in the cloth washing water pool is 12g / L, pump it into the pulping tank as slurry preparation water for recycling; and add a corresponding amount of clear water to the cloth washing water pool;

[0033] (2) Recycling of rinsing water for plate flushing: the rinsing water (containing [Cr 2 O 7 2- ]50~120mg / L, [NH 3 -N]900~1800mg / L, [Mn 2+ ]900~3000mg / L, SS50~300mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com