Treatment method for wastewater produced during flue gas desulphurization through alcohol-amine process

A treatment method, the technology of the alcohol amine method, is applied in the direction of gaseous effluent wastewater treatment, neutralization water/sewage treatment, adsorption water/sewage treatment, etc., to achieve the effect of mild reaction conditions, good treatment effect, and rapid solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

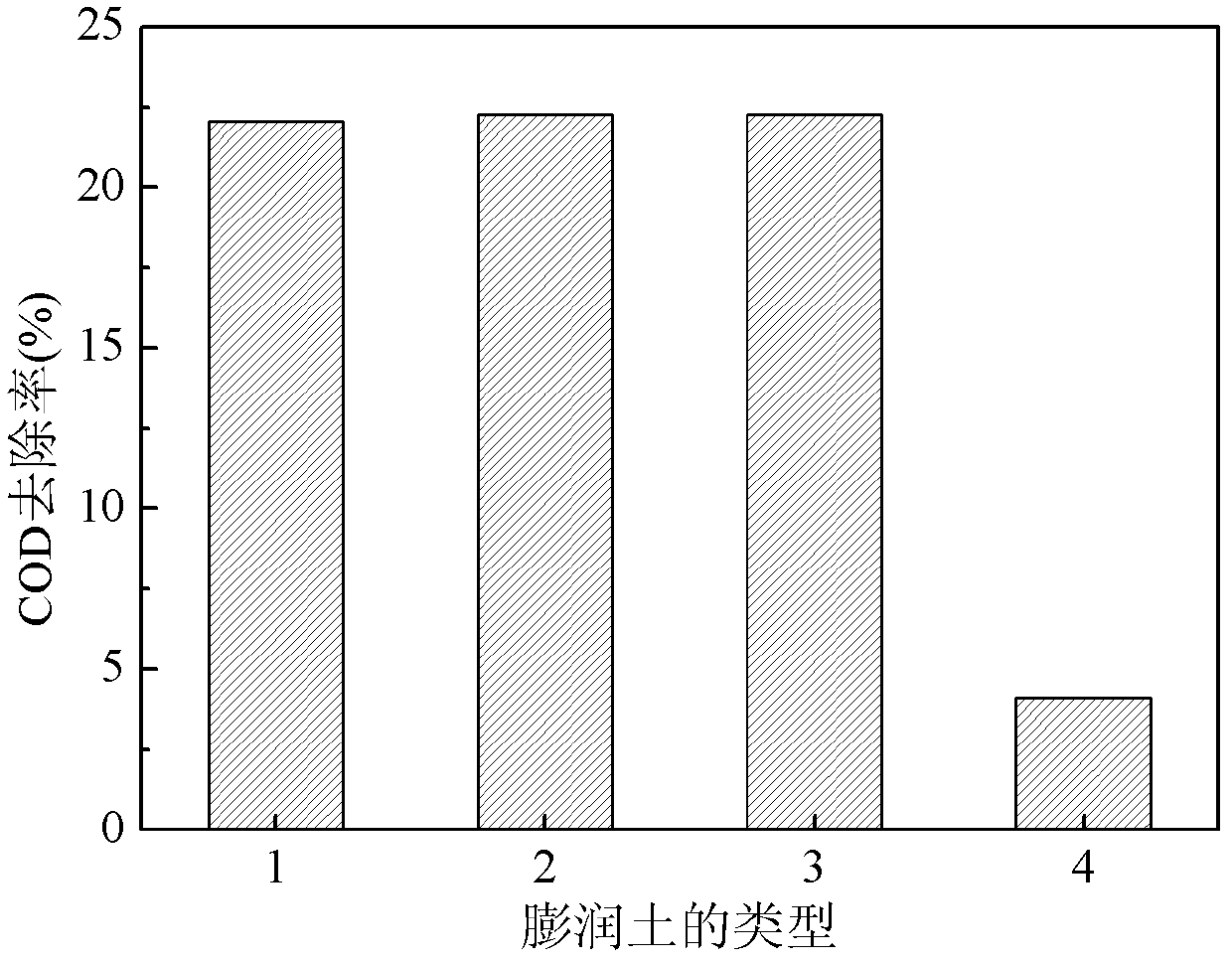

[0029] Add 250ml of simulated wastewater into a 500ml beaker, the initial COD of the wastewater is 6000mg / L, add 1.25g of different types of bentonite (natural sodium bentonite, roasted modified sodium bentonite, cross-linked modified sodium bentonite, organically modified sodium bentonite respectively) base bentonite), stirred and reacted at 200rpm at 30°C for 1h, after natural settlement for 30min, poured out the supernatant, and analyzed COD, the results were as follows figure 1 As shown in the figure, 1 is natural sodium bentonite, 2 is roasted modified sodium bentonite, 3 is crosslinked modified sodium bentonite, and 4 is organically modified sodium bentonite. As can be seen from the figure, natural sodium bentonite, Calcined modified sodium bentonite and cross-linked modified sodium bentonite have the same effect on wastewater treatment, while organically modified sodium bentonite has poor treatment effect. Natural sodium bentonite is preferred in terms of economy and eas...

Embodiment 2

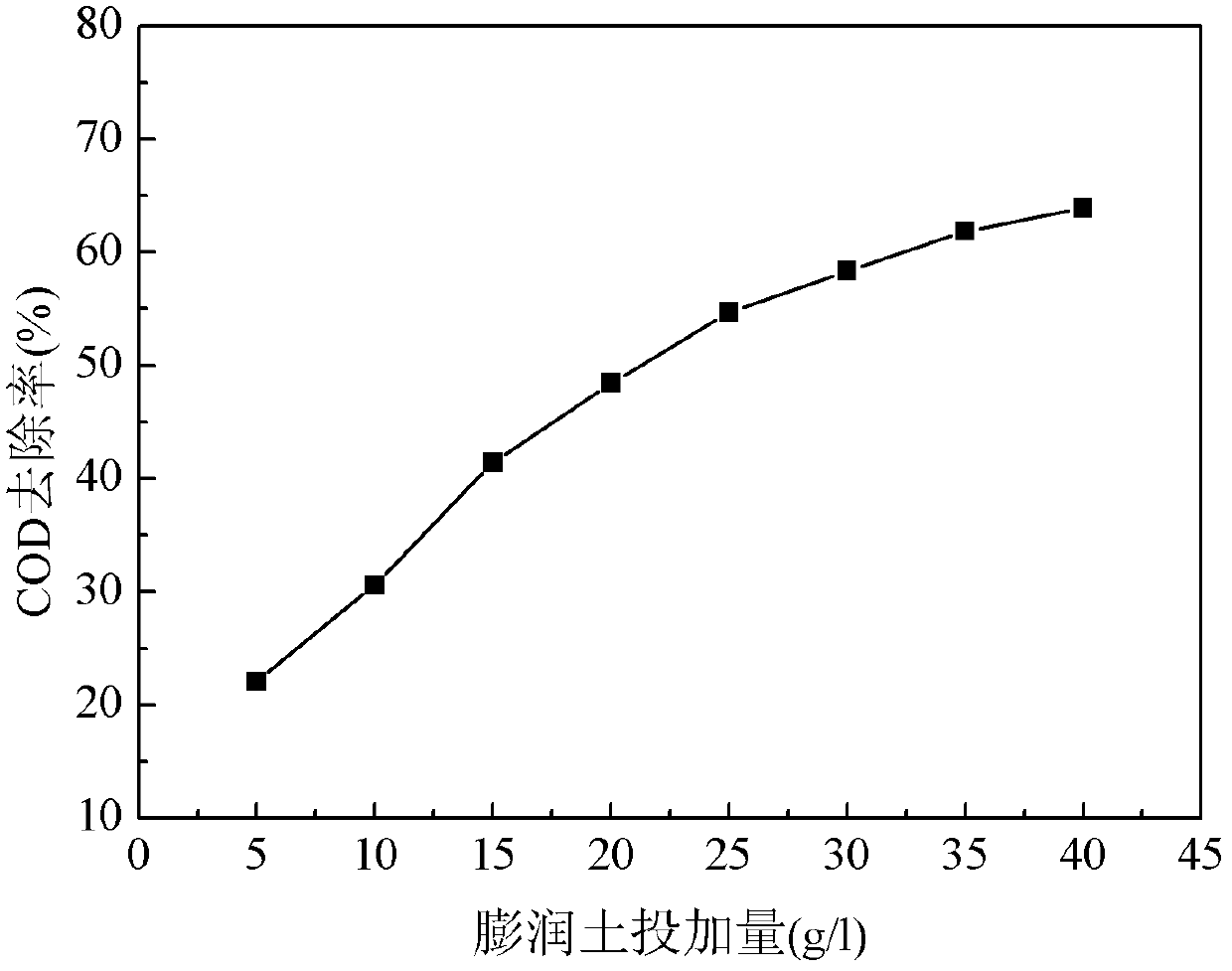

[0031] Add 250ml simulated wastewater into a 500ml beaker, the initial COD of the wastewater is 6000mg / L, add 1.25~10g (according to figure 2 Concentration gradient in) natural sodium-based bentonite, stirred and reacted at 200rpm at 30°C for 1h, after natural sedimentation for 30min, poured out the supernatant, analyzed COD, and the results were as follows figure 2 As shown, it can be seen from the figure that the COD removal rate of wastewater increases with the increase of the amount of bentonite added. When the amount of bentonite added is above 25g / L, the COD removal rate of more than 50% can be achieved, and at this time the addition of bentonite is increased. The increase of volume COD removal rate gradually tends to be slow. Simultaneously, too much addition of bentonite will lead to poor settling properties and make it difficult to separate soil and water, so 25g / L is selected as the addition amount in the following examples.

Embodiment 3

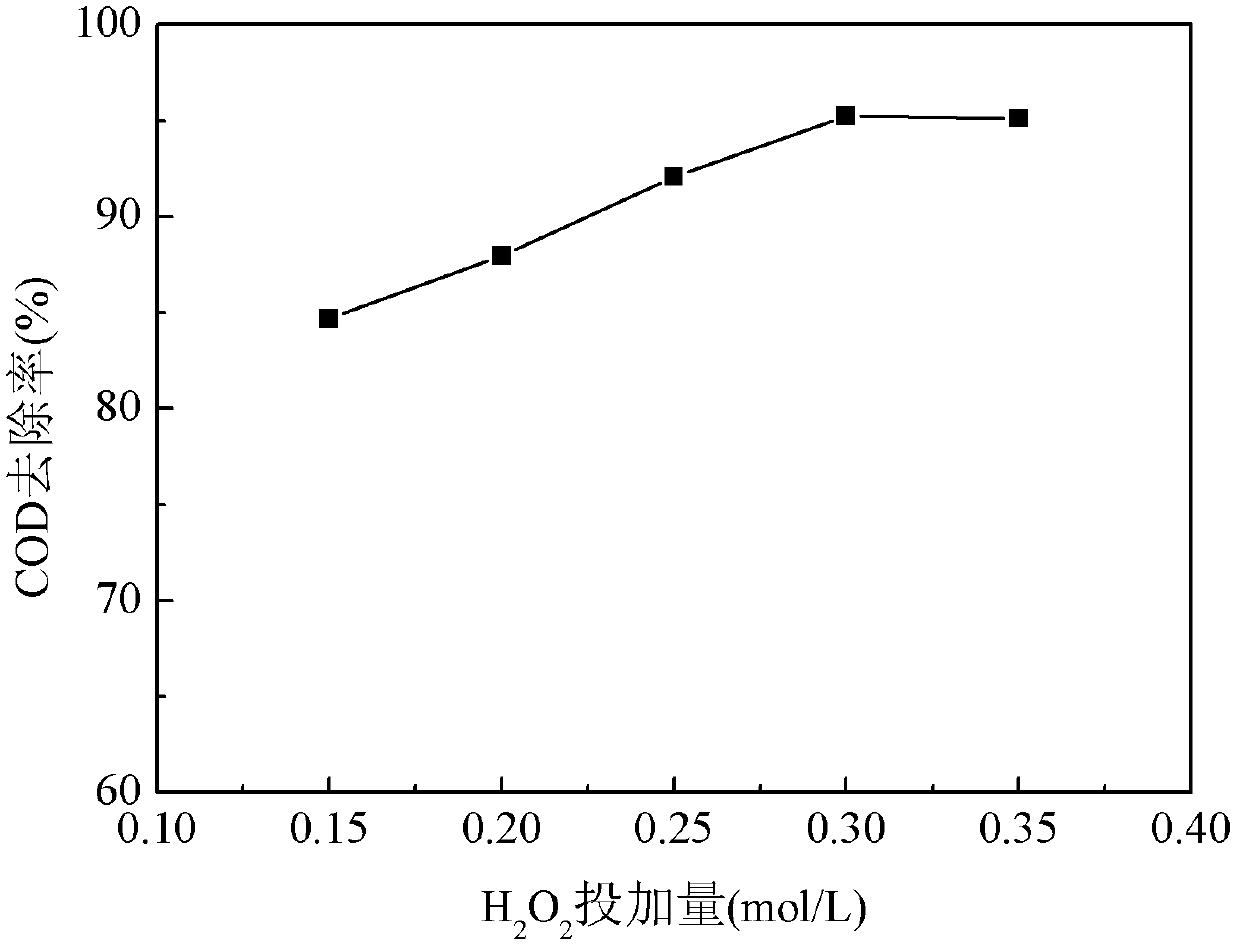

[0033] Add 2L of simulated wastewater into a 3L beaker, the initial COD of the wastewater is 6000mg / L, add 50g of natural sodium bentonite, stir and react at 200rpm at 30°C for 1h, after natural settlement for 30min, pour out the supernatant; Add the supernatant liquid absorbed by natural sodium bentonite into a 500ml beaker, and add 30% H 2 o 2 (that is, add when t=0, t=1h, add half each time), press n(H 2 o 2 ):n(Fe 2+ )=10:1 adding FeSO 4 ·7H 2 O (added at t=0), stirred and reacted at 200rpm at 30°C for 2h, filtered and took the clear liquid to analyze COD, the results were as follows image 3 As shown, it can be seen from the figure that H 2 o 2 The amount of addition has a great influence on the treatment effect, and the removal rate of COD in wastewater increases with H 2 o 2 The amount of addition increases, when H 2 o 2 When the addition amount is 0.3mol / L, the COD removal rate reaches a maximum of 95%, and will not increase thereafter, so 0.3mol / L is select...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com