Solid acrylic resin and preparation method thereof

A solid acrylic acid and methacrylic acid technology, used in applications, coatings, inks, etc., can solve the problems of harsh equipment requirements, large solvent recovery losses, affecting polymer properties, etc. The effect of good adhesion and excellent adhesion

Active Publication Date: 2014-03-12

兰溪市大成胶粘剂厂

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, most solid acrylic resins in China are prepared by recycling solvent after suspension polymerization or solvent polymerization. Suspension polymerization production and later resin cleaning produce a large amount of waste water to pollute the environment; solvent polymerization uses a large amount of initiators, and the initiators reach 5-6% of the monomer ratio. , the residues of initiator decomposition products in the product will affect the performance of the polymer, and at the same time, the loss of solvent recovery is large, and there are safety and environmental pollution problems

There are also foreign countries that use high temperature and high pressure to realize continuous bulk polymerization to synthesize solid acrylic resin, but the requirements for equipment are strict, and there are serious safety hazards in the production process.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

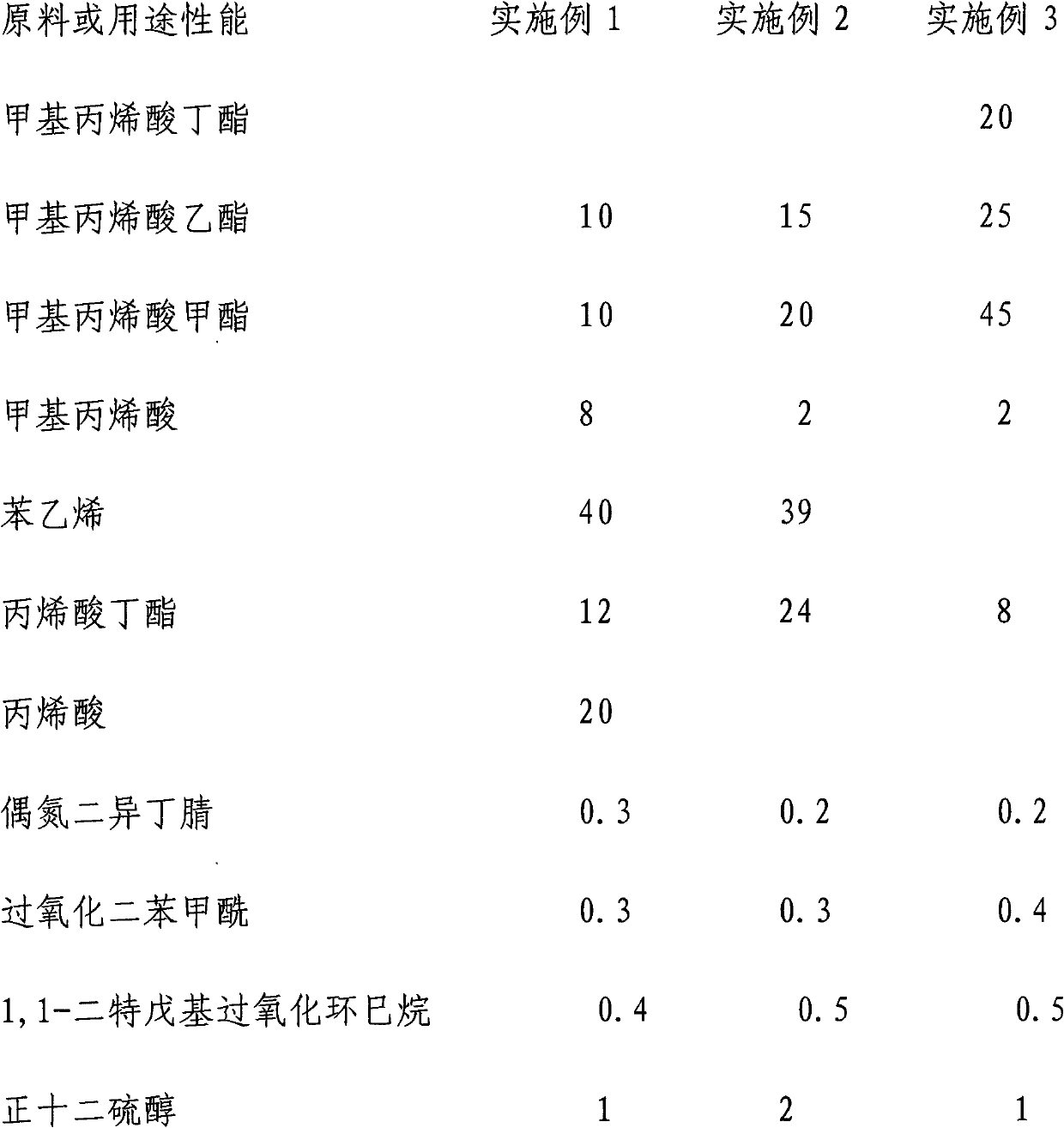

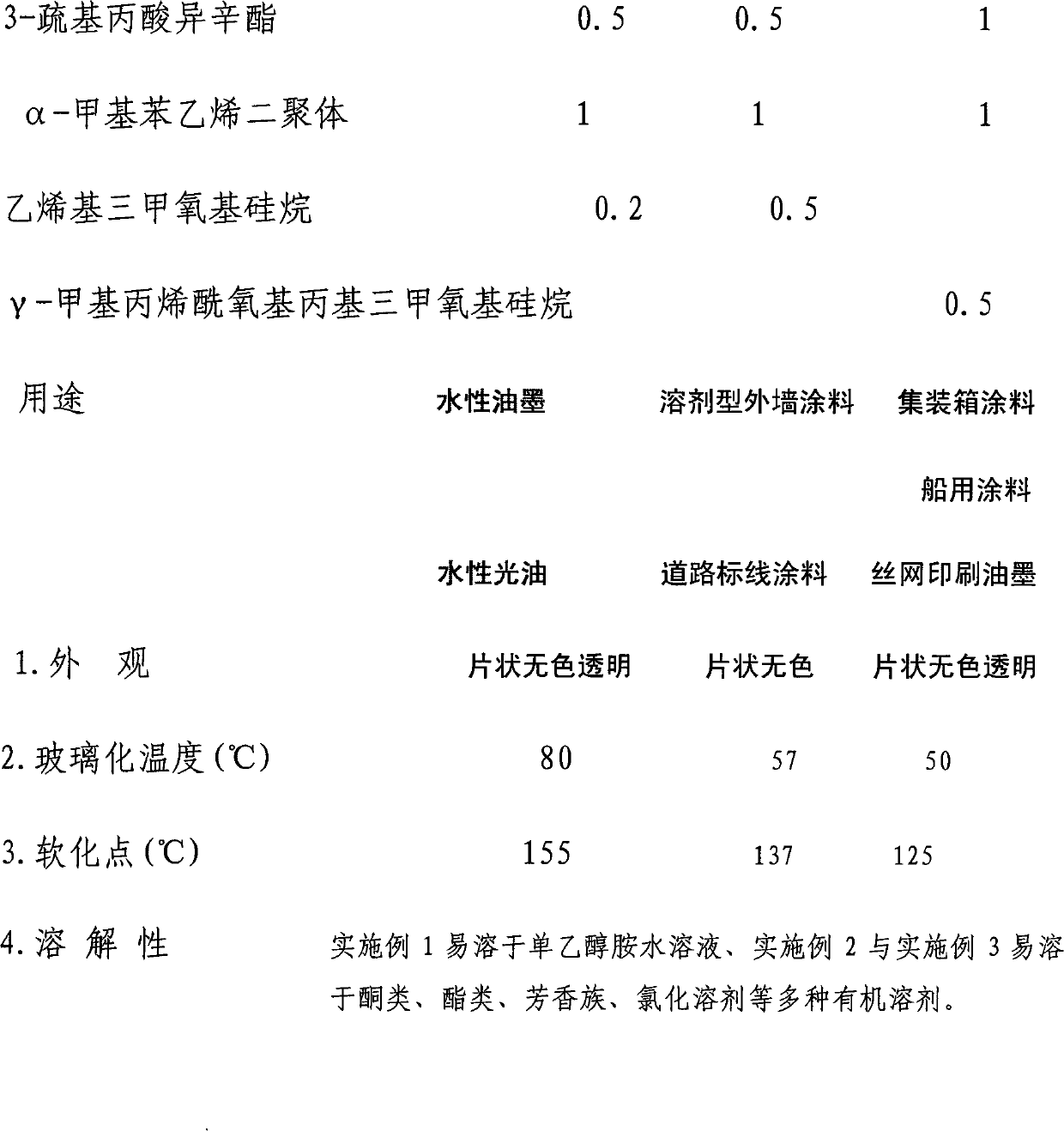

Embodiment 1-3

[0009] Table--1 embodiment formula, polymer performance and purposes

[0010]

[0011]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses solid acrylic resin and a preparation method of the solid acrylic resin. The solid acrylic resin comprises the following components by weight percent: 10-92 parts of metacrylic acid ester, 5-40 parts of acrylic ester, 0-40 parts of vinyl benzene, 0-30 parts of combination of acrylic acid and methacrylic acid, 0.6-2 parts of combination of azoic compound and hyperoxide, 1-10 parts of combination of N-dodecyl mercaptan, isooctyl 3-mercaptopropionate iomp and Alpha-methyl styrene dimer, and 0.2-2 parts of organosilicon monomer vinyltrimethoxysilane or gamma- trimethoxysilyl-propyl-methacrylate. The preparation method comprises the steps of a) prepolymerization: polymerizing the above components for 2-8 hours under 60-85 DEG C to obtain glycerol-state prepolymer; and b) oast polymerization: polymerizing the prepolymer with subsection temperature control in an oast, wherein the starting polymerization temperature is 50-120 DEG C, and the oast polymerization time is 20-40 hours. The solid acrylic resin and the preparation method of the resin have excellent adhesive force, heat resistance, water resistance, stain resistance and mechanical property.

Description

1. Technical field [0001] The invention belongs to the technical field of polymer new material preparation. 2. Background technology [0002] Compared with solvent-based, emulsion-based, and solvent-to-water-based acrylic resins, solid acrylic resins have unique performance advantages, and are safer and more economical to store, transport and use. They are high-end products of acrylic polymers. At present, most solid acrylic resins in China are prepared by recycling solvent after suspension polymerization or solvent polymerization. Suspension polymerization production and later resin cleaning produce a large amount of waste water to pollute the environment; solvent polymerization uses a large amount of initiators, and the initiators reach 5-6% of the monomer ratio. , The residues of initiator decomposition products in the product mostly affect the performance of the polymer, and at the same time, the solvent recovery loss is large, and there are safety and environmental poll...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F212/08C08F220/18C08F220/14C08F220/06C08F230/08C08F4/38C08F4/04C08F2/38C09D11/107C09D125/14C09D133/12

Inventor 祝一帆

Owner 兰溪市大成胶粘剂厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com