High-resilience polyurethane elastomer compound

A technology of polyurethane elastomer and polyurethane elasticity, which is applied in the field of chemical synthesis and can solve problems such as difficulty, high cost, and limitation of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

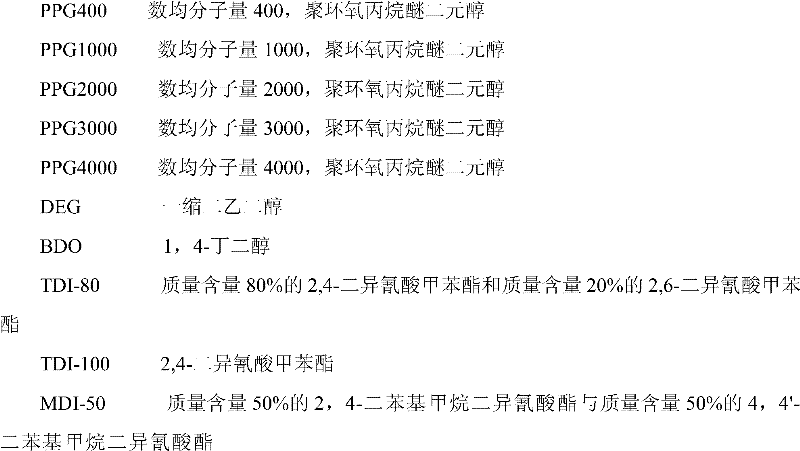

Method used

Image

Examples

Embodiment 1

[0016] Prepolymer: polyether polyol (PPG2000) 54.5%, polyether polyol (PPG400) 14.3%, 1,4-butanediol (BDO) 2.0%, toluene diisocyanate (TDI-100) 29.2%, at 80 ℃ ℃ for 3 hours, vacuum (-0.095MPa) to remove air bubbles, to obtain a prepolymer with an isocyanate content of 7.0%;

[0017] Curing agent: 3,3'-dichloro-4,4'-diaminodiphenylmethane;

[0018] Curing agent and prepolymer with NH 2 / NCO=0.9 equivalence ratio for mixing reaction, quickly poured into the preheated mold, wherein, the mixing temperature is 80 ° C, the mold temperature is 120 ° C, demoulding in 40 minutes, adjusted to 110 ° C and vulcanized for 10 hours, A polyurethane elastomer product with a hardness of 98A and a rebound of 41% was obtained.

Embodiment 2

[0020] Prepolymer: 30.5% polyether polyol (PPG1000) with a molecular weight of 1000, 43.5% polyether polyol (PPG4000) with a molecular weight of 4000, 2.7% diethylene glycol (DEG), toluene diisocyanate (TDI-80) 13.3%, toluene diisocyanate (TDI-100) 10.0%, react at 90°C for 2 hours, vacuum (-0.095MPa) to remove air bubbles, and obtain a prepolymer with an isocyanate content of 5.5%;

[0021] Curing agent: 3,3'-dichloro-4,4'-diaminodiphenylmethane;

[0022] Curing agent and prepolymer with NH 2 / NCO=0.9 equivalence ratio for mixing reaction, quickly poured into the preheated mold, wherein, the mixing temperature is 80 ° C, the mold temperature is 120 ° C, demoulding in 40 minutes, adjusted to 110 ° C and vulcanized for 10 hours, A polyurethane elastomer product with a hardness of 91A and a rebound of 45% was obtained.

Embodiment 3

[0024] Prepolymer: polyether polyol (PPG3000) with a molecular weight of 3000 (PPG3000) 65.2%, polyether polyol (PPG400) with a molecular weight of 400 (PPG400) 10.6%, diphenylmethane diisocyanate (MDI-50) 24.2%, react at 70°C for 3 Hour, vacuum (-0.095MPa) removes air bubbles, obtains the prepolymer that isocyanate content is 4%;

[0025] Curing agent: 3,3'-dichloro-4,4'-diaminodiphenylmethane;

[0026] Curing agent and prepolymer with NH 2 / NCO=0.9 equivalence ratio for mixing reaction, quickly poured into the preheated mold, wherein, the mixing temperature is 80 ° C, the mold temperature is 120 ° C, demoulding in 40 minutes, adjusted to 110 ° C and vulcanized for 10 hours, A polyurethane elastomer product with a hardness of 83A and a rebound of 47% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com