Stibium blast furnace for generating antimony matte, device of coarse stibium blowing furnace and direct converting method

A technology of antimony blast furnace and crude antimony, which is applied in the field of antimony blast furnace to produce antimony matte and crude antimony volatilization furnace, which can solve the problems of large energy consumption, insufficient use of heat energy, and increased production cost of antimony blast furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

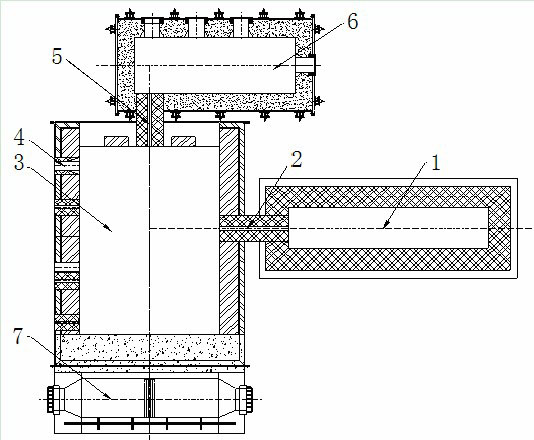

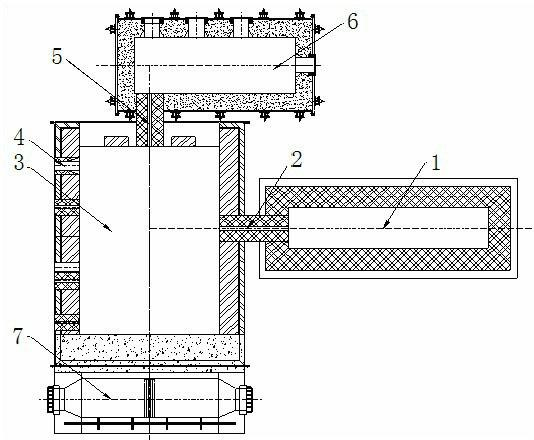

[0016] Embodiment 1: Antimony blast furnace produces antimony matte, crude antimony blowing furnace direct blowing device

[0017] It includes an antimony blast furnace 1 and an antimony blast furnace front bed 3 arranged above the front bed burner 7, a slag passage 2 is provided between the antimony blast furnace 1 and the antimony blast furnace front bed 3, and the blowing furnace 6 is arranged on the antimony blast furnace front bed At the end of the furnace, there is an antimony channel 5 between the blowing furnace and the front bed of the antimony blast furnace.

Embodiment 2

[0019] The device of embodiment 1 is applied to the method of direct blowing:

[0020] (1) After the antimony-containing material is oxidized and volatilized by the antimony blast furnace, most of the antimony enters the condensation dust collection system in the gaseous state of antimony trioxide; a small part of antimony enters the slag phase in the form of antimony matte and coarse antimony;

[0021] The antimony matte, crude antimony and molten slag phase in step (2) and (1) enter the front bed of the antimony blast furnace together. In the front bed of the antimony blast furnace, the proportion of antimony matte and crude antimony is 6.5×10 3 kg / m 3 , while the specific gravity of slag is 3.0×10 3 kg / m 3 , the slag floats on the antimony matte and crude antimony; realize the separation of antimony matte, crude antimony and slag;

[0022] (3) Antimony matte and crude antimony enter the blowing furnace directly through the antimony channel; after the liquid level of the...

Embodiment 3

[0025] Embodiment 3: Different from Embodiment 2:

[0026] at 1.0m 2 Set 1.0m at the tail end of the front bed of the antimony blast furnace 2 The blowing furnace treats the antimony matte and crude antimony melt produced by the antimony blast furnace. The average antimony grade of antimony matte and crude antimony is 75.1%, and the average gold content is 105g / t. The output rate of antimony trioxide in the blowing furnace is 92.8%. The recovery rate is 9.3%, the precious antimony contains 1098g / t of gold, and the comprehensive recovery rate of gold is 93.07%. Blast furnace unit bed capacity: 27.9t / m 2 .d, coke rate 31.0%, iron ore rate 34.5%, antimony comprehensive recovery rate 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com