Method for preparing FeSe superconducting thin film by post-selenization treatment

A technology of superconducting thin film and processing method, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of no major breakthrough, high maintenance cost, and reduced yield, and achieve the goal of being independent of size. Limit, reduce impurity phase, reduce stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the first step, lanthanum aluminate (LaAlO 3 ) the surface of the single crystal substrate is cleaned with acetone and alcohol;

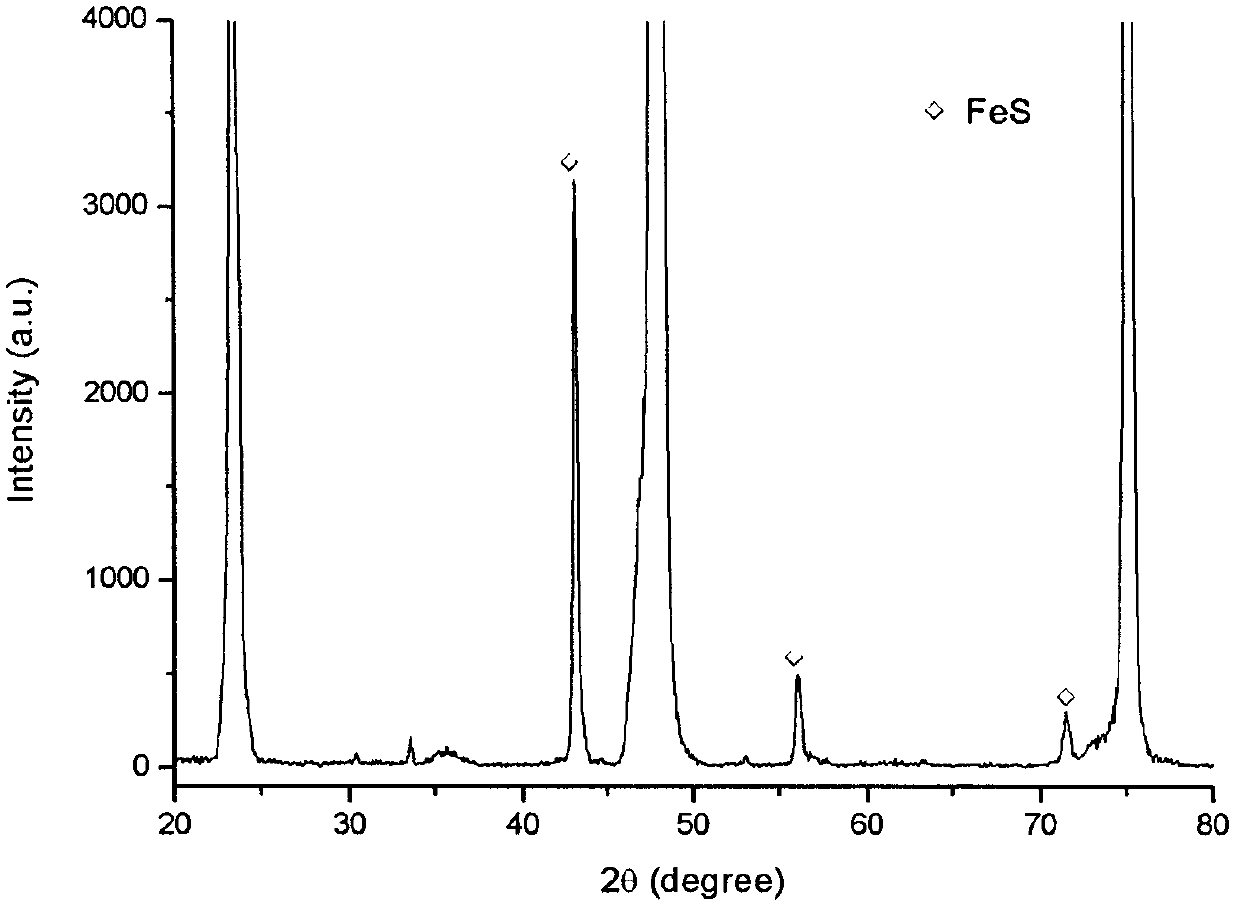

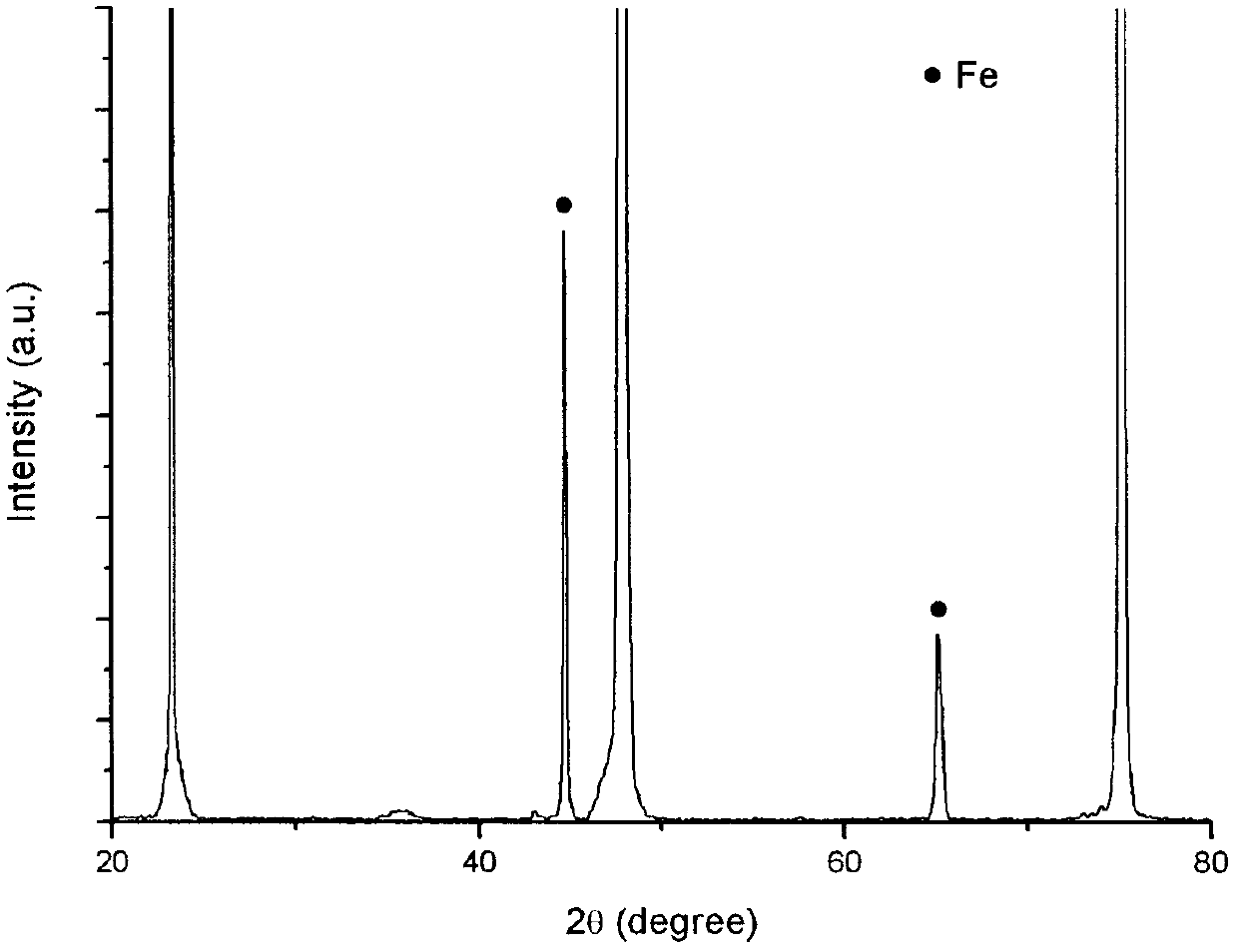

[0027] The second step is to deposit a layer of FeS film with a thickness of about 4 μm on the cleaned LAO single crystal substrate by reactive sputtering film deposition technology. Specific sputtering deposition conditions: substrate temperature 400°C, target material is Fe target with a purity of 99.99% , back vacuum degree 5.0×10 -3 Pa, H 2 The S reaction gas flow rate is 40 sccm, the sputtering power is 100 W, and the target base distance is 40 mm.

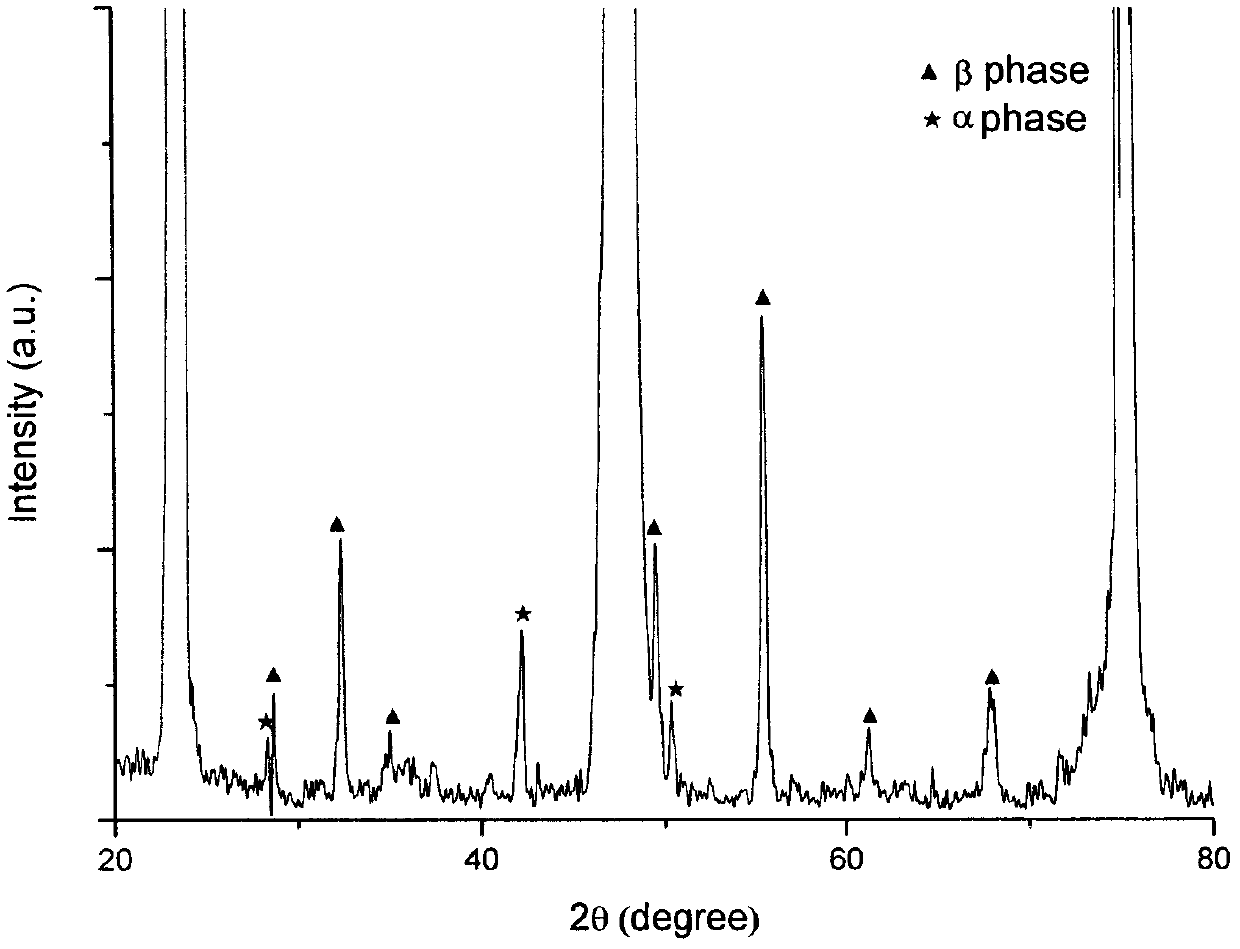

[0028] The third step is to use a semi-automatic electro-optic balance to weigh 3.8 mg of amorphous elemental selenium. The elemental selenium is weighed by a semi-automatic electro-optic balance, and the deposited FeS film is placed in a quartz tube with a diameter of 20 mm. The combination of pump and mechanical pump is used for pumping, the other end is heated by a high-temperature ...

Embodiment 2

[0031] In the first step, lanthanum aluminate (LaAlO 3 ) the surface of the single crystal substrate is cleaned with acetone and alcohol;

[0032] The second step is to deposit a layer of FeS film with a thickness of about 10 μm on the cleaned LAO single crystal substrate by reactive sputtering film deposition technology. Specific sputtering deposition conditions: substrate temperature 500°C, target material is Fe target with a purity of 99.99% , back vacuum degree 4.0×10 -3 Pa, H 2 The S reaction gas flow rate is 20 sccm, the sputtering power is 120 W, and the target base distance is 60 mm.

[0033] The third step is to use a semi-automatic electro-optic balance to weigh 16 mg of amorphous elemental selenium. The elemental selenium is weighed by a semi-automatic electro-optic balance, and placed in a quartz tube with a diameter of 20 mm together with the deposited FeS film, and vacuum-sealed, that is, a diffusion pump is used at one end The combination of mechanical pump i...

Embodiment 3

[0036] In the first step, lanthanum aluminate (LaAlO 3 ) the surface of the single crystal substrate is cleaned with acetone and alcohol;

[0037] The second step is to deposit a layer of FeS film with a thickness of about 3 μm on the cleaned LAO single crystal substrate using reactive sputtering film deposition technology. Specific sputtering deposition conditions: substrate temperature 200 ° C, target material is Fe target with a purity of 99.99% , back vacuum degree 6.0×10 -3 Pa, H 2 The S reaction gas flow rate is 30 sccm, the sputtering power is 60 W, and the target base distance is 50 mm.

[0038] In the third step, 0.2 mg of amorphous elemental selenium was weighed with a semi-automatic electro-optic balance, and placed in a quartz tube with a diameter of 20 mm together with the deposited FeS film, and vacuum-sealed, and the vacuum degree in the quartz tube was 1×10 -3 Pa.

[0039] In the fourth step, the sealed quartz tube is placed in a heating furnace to raise th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com