Preparation method of Al-Ag alloy powder plated with silver chemically

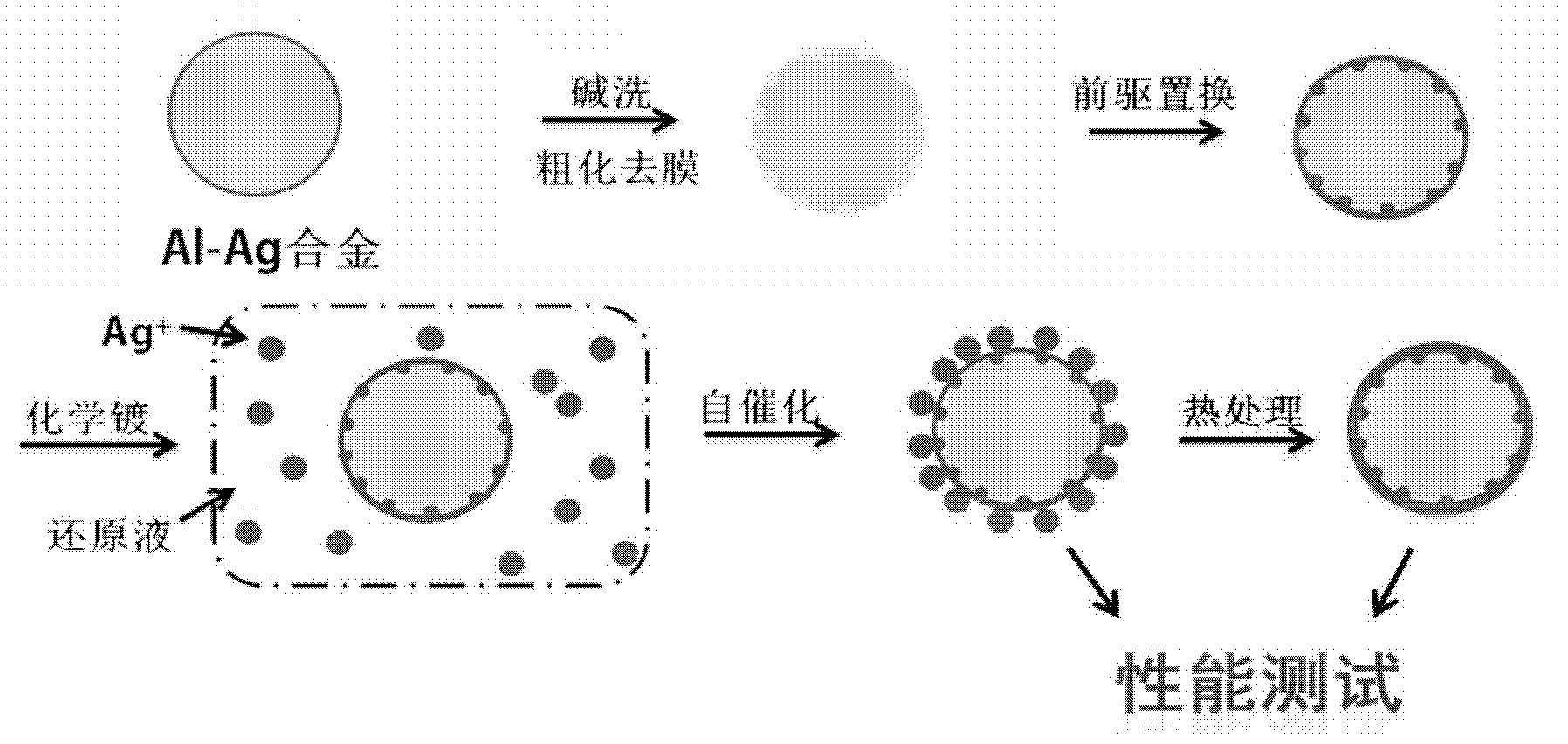

An electroless silver plating and alloy powder technology, applied in the field of electroless plating, can solve the problems of poor powder uniformity and cumbersome pretreatment process, etc., achieve complete and uniform silver coating, reduce cost and energy consumption, and improve bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of Al-Ag alloy powder: Spray alloy powder with a silver content of 1 wt%.

[0023] 2) Pretreatment of Al-Ag alloy powder: take 2g of alloy powder and corrode it with a NaOH solution with a concentration of 0.02wt%. all over.

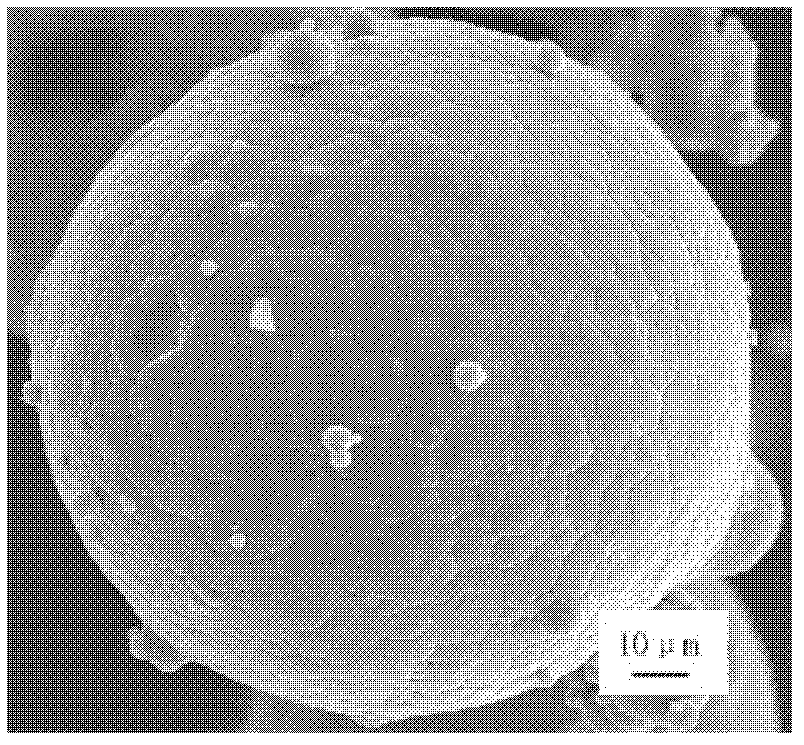

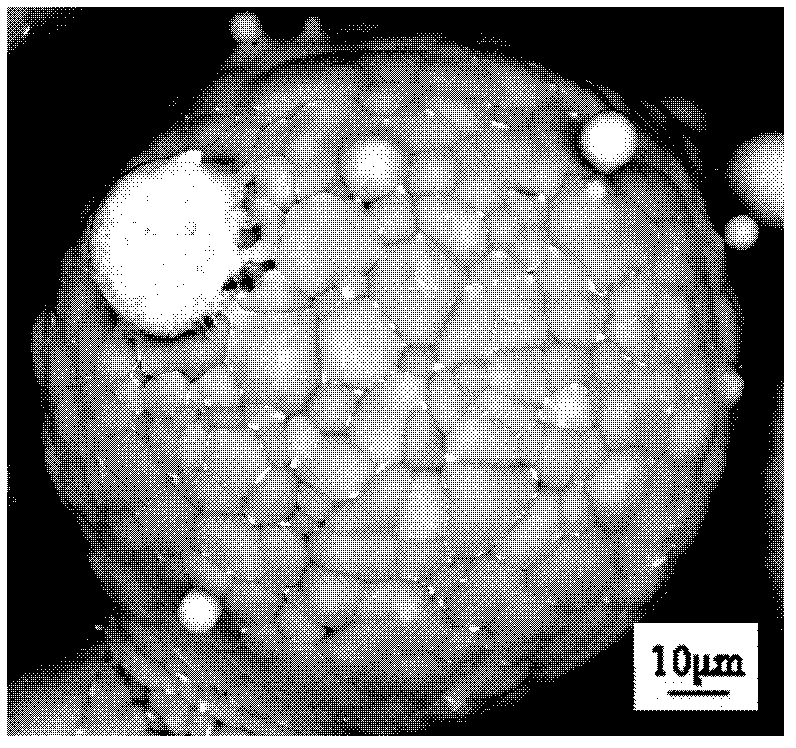

[0024] 3) Silver-coated Al-Ag alloy powder: at room temperature and normal pressure, place the alloy powder in a silver nitrate solution with a concentration of 10wt% for precursor replacement reaction; after replacement for 30 minutes, separate the powder and place it in a 100ml In the electroless silver plating reducing solution, the reducing solution is composed of glucose (27g / L), thiourea (2mg / L), tartaric acid (4g / L), absolute ethanol, etc., and the silver salt is silver ammonia solution (50g / L) , under ultrasonic conditions, drop 50ml of silver ammonia solution into the reducing solution drop by drop, the pH is 11.5, the temperature is 30°C, and react for 20min; after the plating is finished, wash with water and dry in vacuu...

Embodiment 2

[0027] 1) Preparation of Al-Ag alloy powder: Spray alloy powder with a silver content of 3 wt%.

[0028] 2) Pretreatment of Al-Ag alloy powder: take 4g of alloy powder, corrode it with a NaOH solution with a concentration of 0.03wt%, and when fine bubbles are seen to be precipitated, the alloy powder after the film removal and coarsening is rapidly washed with deionized water for 3 all over.

[0029] 3) Silver-coated Al-Ag alloy powder: at room temperature and normal pressure, place the alloy powder in a silver nitrate solution with a concentration of 5wt% for precursor replacement reaction; after 30 minutes of replacement, separate the powder and place it in a 100ml In the electroless silver plating reducing solution, the reducing solution is composed of glucose (27g / L), thiourea (2mg / L), tartaric acid (4g / L), absolute ethanol, etc., and the silver salt is silver ammonia solution (50g / L) , under ultrasonic conditions, drop 50ml of silver ammonia solution into the reducing so...

Embodiment 3

[0032] 1) Preparation of Al-Ag alloy powder: Spray alloy powder with a silver content of 5 wt%.

[0033] 2) Pretreatment of Al-Ag alloy powder: take 3g of alloy powder and corrode it with a NaOH solution with a concentration of 0.02wt%. all over.

[0034] 3) Silver-coated Al-Ag alloy powder: at room temperature and normal pressure, place the alloy powder in a silver nitrate solution with a concentration of 10wt% for precursor replacement reaction; after the replacement for 40 minutes, separate the powder and place it in a 100ml In the electroless silver plating reducing solution, the reducing solution is composed of glucose (27g / L), thiourea (2mg / L), tartaric acid (4g / L), absolute ethanol, etc., and the silver salt is silver ammonia solution (50g / L) , under ultrasonic conditions, drop 50ml of silver ammonia solution into the reducing solution drop by drop, the pH is 11.5, the temperature is 35°C, and react for 30min; after the plating is finished, wash with water and dry in v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap