Device for generating metal magnesium by electrolyzing magnesium chloride

A technology of metal magnesium and magnesium chloride, applied in electrolytic components, electrolytic process, etc., can solve the problems of poor sealing of electrolytic cell cover, low temperature of electrolyte, high labor intensity, etc., to improve single cell production capacity, improve working environment, improve The effect of electrolytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

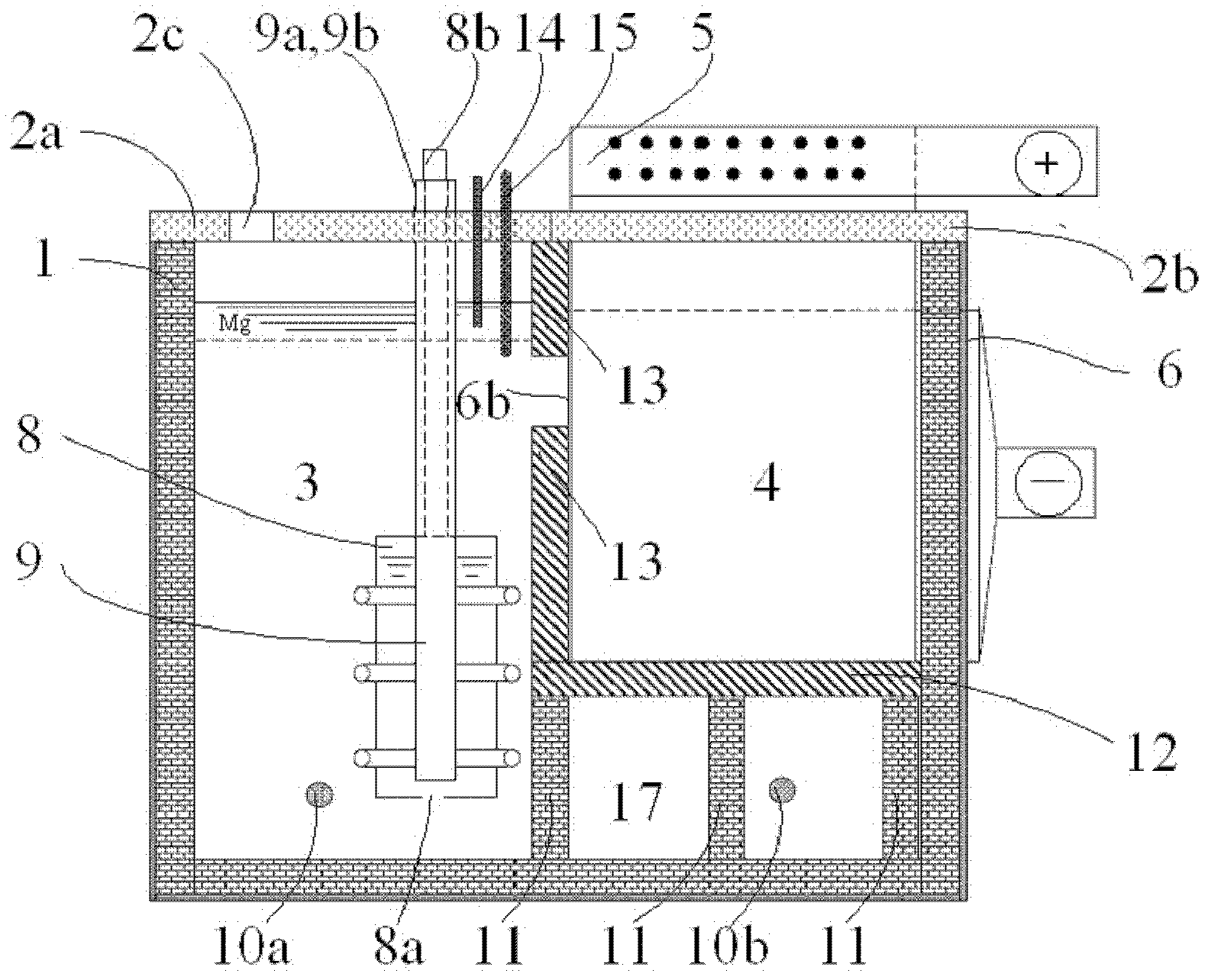

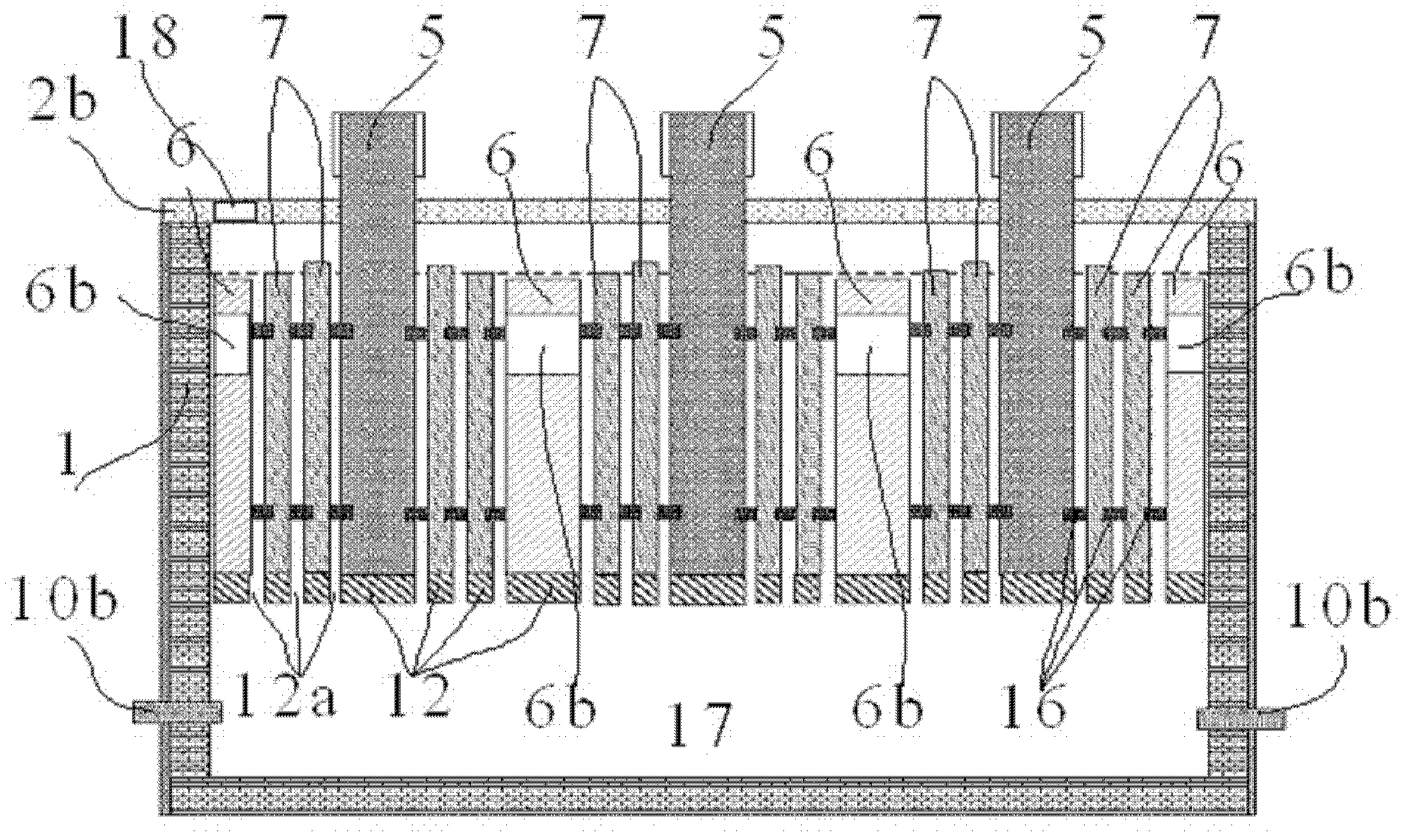

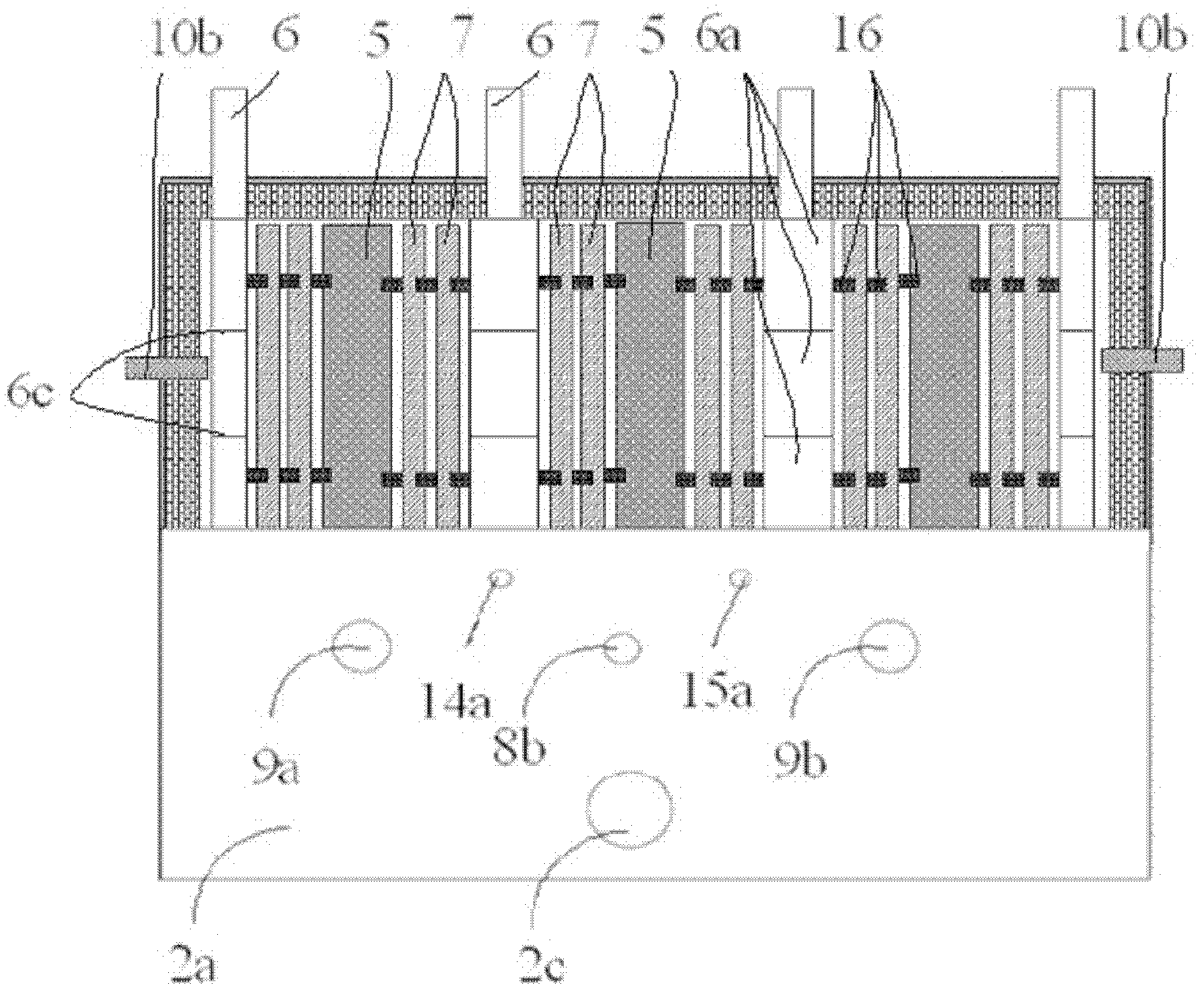

[0046] see Figure 1-4 1. A device for electrolyzing magnesium chloride to produce metal magnesium, comprising a temperature control system, a liquid level control system and an electrolytic cell 1; a partition plate 13 is set in the electrolytic cell 1 to divide the upper part of the electrolytic cell 1 into an electrolytic chamber 4 and a magnesium collection chamber 3, In addition, a magnesium guide port 6b is provided on the separator 13 .

[0047] Three carbon anodes 5 and four iron cathodes 6 are installed in the electrolysis chamber 4, and two bipolar electrodes 7 are inserted between the anodes 5 and cathodes 6, and the electrolysis chamber 4 is divided into three electrolysis units. An insulated support plate 12 for supporting the electrodes is provided at the lower part of the electrolysis chamber 4, and the support plate 12 can fix the electrodes relatively firmly to prevent the electrodes from shifting during the electrolysis process. The support plate 12 is provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com