Active driving cable table

An active drive, cable table technology, applied in the field of cable table, can solve the problems of control difficulty, increase the mass of the rough moving part of the workpiece table, increase the additional torque of the cable table, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

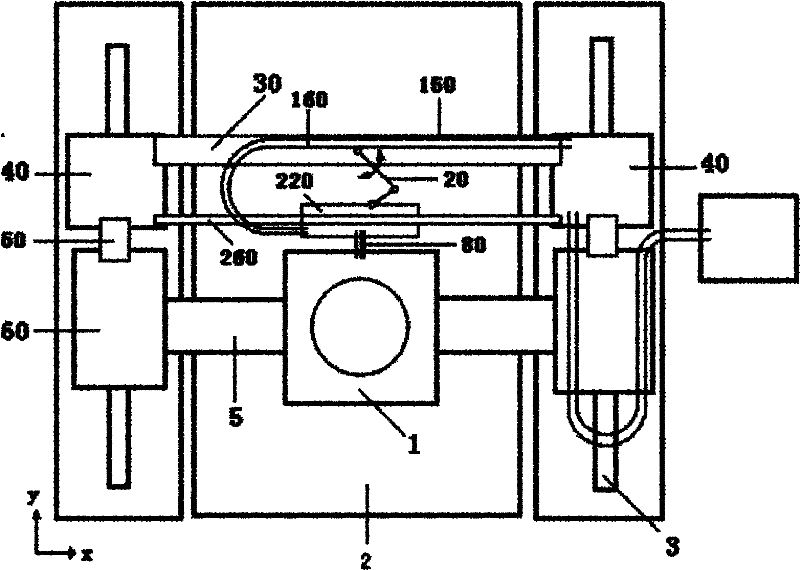

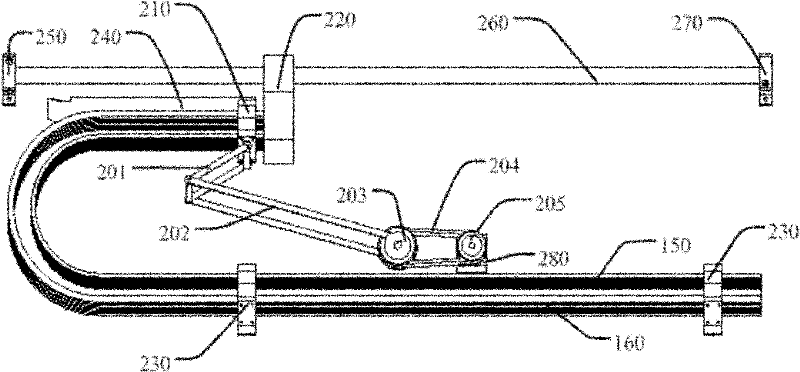

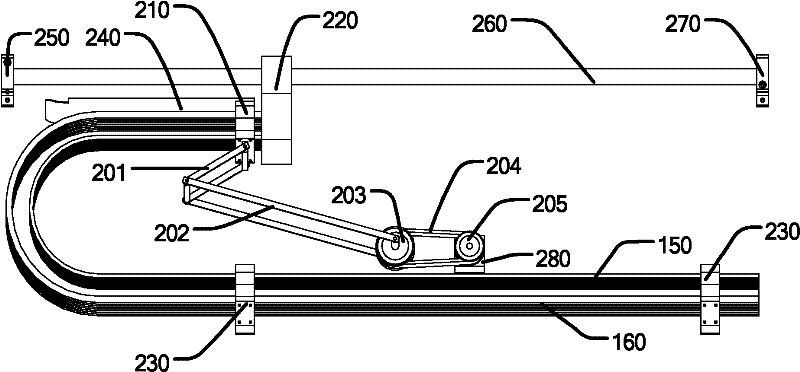

[0021] The following will combine Figure 1 ~ Figure 2 A further detailed description will be made on the actively driven cable platform of the present invention.

[0022] figure 1 Shown is a schematic layout diagram of the precision workpiece table and the active drive cable table. The workpiece table 1 is set on the X-guiding rail 5, and the two sides of the workpiece table 1 are respectively connected to the lateral sides of the X-guiding rail 5 by means of air bearings. , the bottom of the workpiece table 1 is provided with an air bearing hole and a vacuum chamber (not shown in the figure), thereby forming an air bearing with bidirectional rigidity. The two-way stiffness mentioned here means that the air floating block (i.e. the workpiece table 1) is connected to an external pressure pump to make compressed air pass through the air floating hole to generate buoyancy, and the external vacuum pump connected to the vacuum chamber simultaneously extracts the air in the chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com