Microelectrode array with adjustable electrode point distance

A micro-electrode array and electrode technology, which is applied in the field of medical devices, can solve the problems of micro-electrode arrays with variable electrode point distances that have not been reported, and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

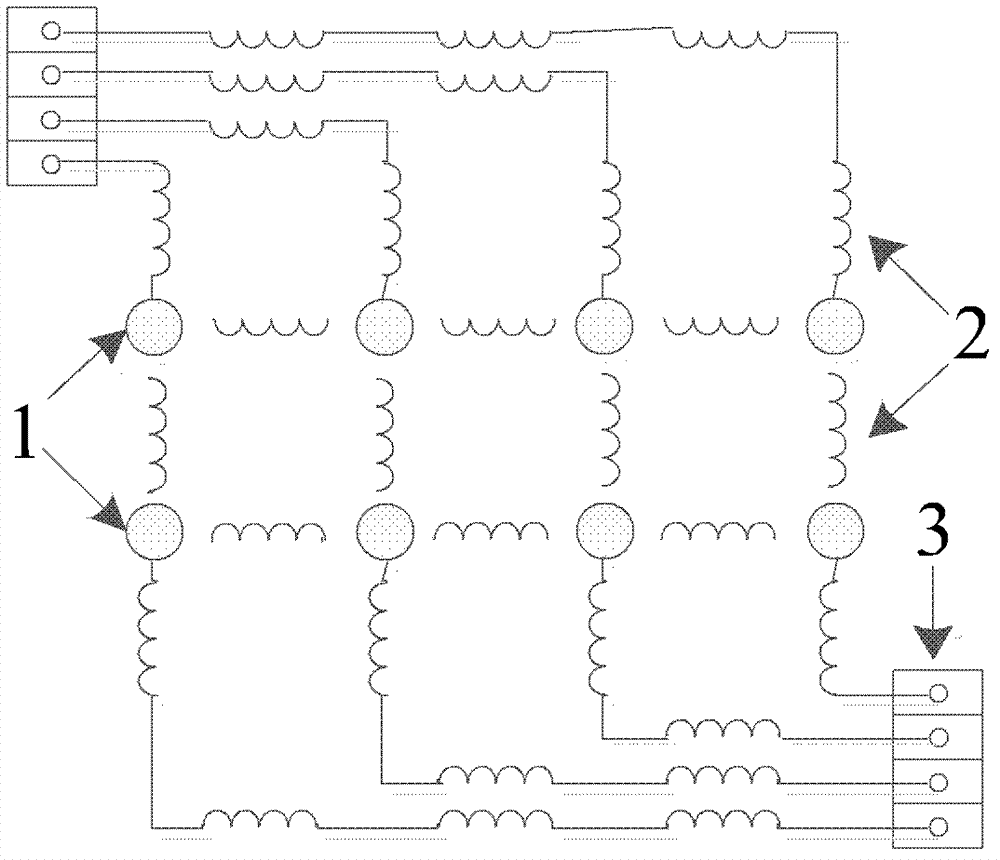

[0025] Such as figure 1 As shown, the microelectrode array described in this embodiment includes: a microelectrode array structure layer, an electrode circuit layer, and a microelectrode array covering layer, wherein: the electrode circuit layer is sandwiched between the microelectrode array structure layer and the microelectrode array covering layer . Considering that the three-layer structure of the microelectrode array has been described in detail in the patent (application number 201110110285.0, application publication number CN 102178998A), only the characteristics of the electrode circuit layer will be highlighted here.

[0026] In this embodiment, the electrode circuit layer includes electrode points 1 , a buffer structure 2 that facilitates adjustment of the distance between the electrode points, and connection points 3 with peripheral circuits.

[0027] In this embodiment, the distribution distance and distribution density of the buffer structures 2 in the electrode ...

Embodiment 2

[0044] This embodiment provides the preparation method of the microelectrode array described in Embodiment 1, and the specific process is as follows:

[0045] Firstly, 10 μm PDMS (polydimethylsiloxane) was cast on the Si wafer and cured to form a microelectrode structure layer;

[0046] Then throw a 5 μm positive resist and pattern it, sputter the noble metal (including Pt, Ir, Au, etc.) seed layer, 100-15000 angstroms, use the Lift-off process to remove the photoresist, pattern the seed layer, and form the electrode circuit layer;

[0047] Then throw 10μm PDMS (polydimethylsiloxane) and cure it, pattern the photoresist for the second time, and use reactive ion etching (RIE) to etch through Parylene-C to expose the electrode points to form a microelectrode Array overlay.

Embodiment 3

[0049] This embodiment provides the preparation method of the microelectrode array described in Embodiment 1. In this embodiment, polychlorinated p-xylylene (Parylene-C) is used for the microelectrode structure layer and the covering layer, and the preparation process is as follows:

[0050] First deposit a 5 μm polychlorinated p-xylylene (Parylene-C) film on the Si wafer, then throw a 5 μm positive resist and pattern it, and sputter a noble metal (including Pt, Ir, Au, etc.) seed layer, 100-15000 Angstroms, Use the Lift-off process to remove the photoresist, pattern the seed layer, and form the electrode circuit layer. Then deposit 5 μm of Parylene-C, pattern the photoresist for the second time, and use reactive ion etching (RIE) to etch through Parylene-C to expose electrode points to form a microelectrode array covering layer.

[0051] In summary, using the microelectrode array with adjustable electrode point spacing to collect and stimulate electrophysiological signals, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com