Method and device for producing high-purity natural graphite

A natural graphite and pure natural technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high initial investment, long reaction time, difficult treatment of waste water and tail gas, etc., and achieve low equipment cost and high production efficiency. The effect of high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

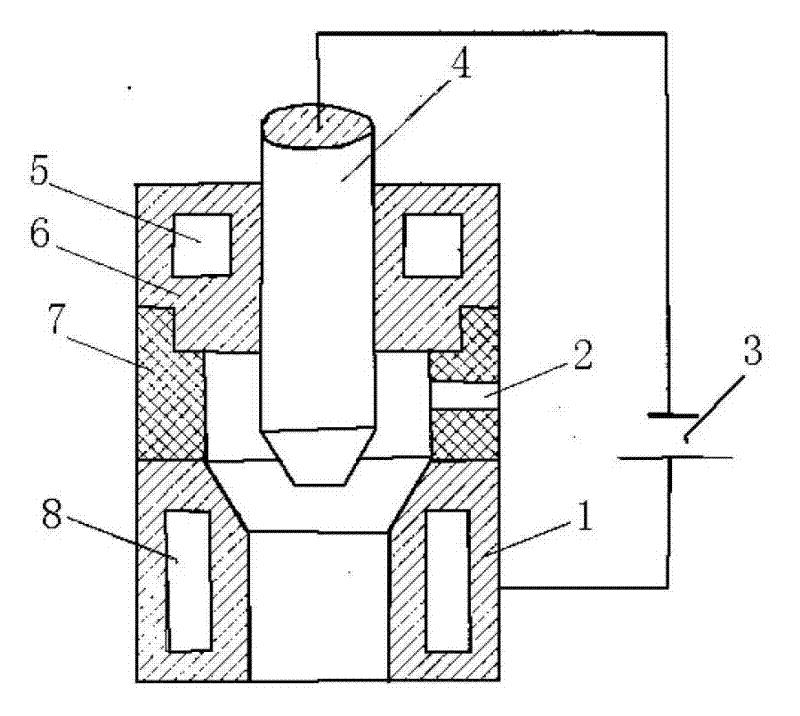

[0020] Weigh natural graphite powder with a purity of 90%-98%, and start a special device for producing high-purity natural graphite (see figure 1 ), argon gas pressure: 0.8MPa, powder feeding volume 100g / min, cooling water flow rate: 1.2M / s, using 80KW plasma generator, adjust its working current 20-60A, working voltage: 30-50V, so that the plasma generator A high temperature zone of 3000-3600°C is generated between the cathode and anode. The gas and powder channel is designed in the insulator, the inner diameter of the gas and powder channel is 10mm, and the natural graphite powder is carried into the plasma generator by the inert gas argon. zone, so that all the ash in the graphite (mainly containing SiO 2 、A1 2 o 3 , Fe 2 o 3 , CaO, MgO) gasification and volatilization; during the purification process, the natural graphite powder is always in the protection state of the inert gas. The test results show that the quality purity of graphite is above 99.9%, and the origi...

Embodiment 2

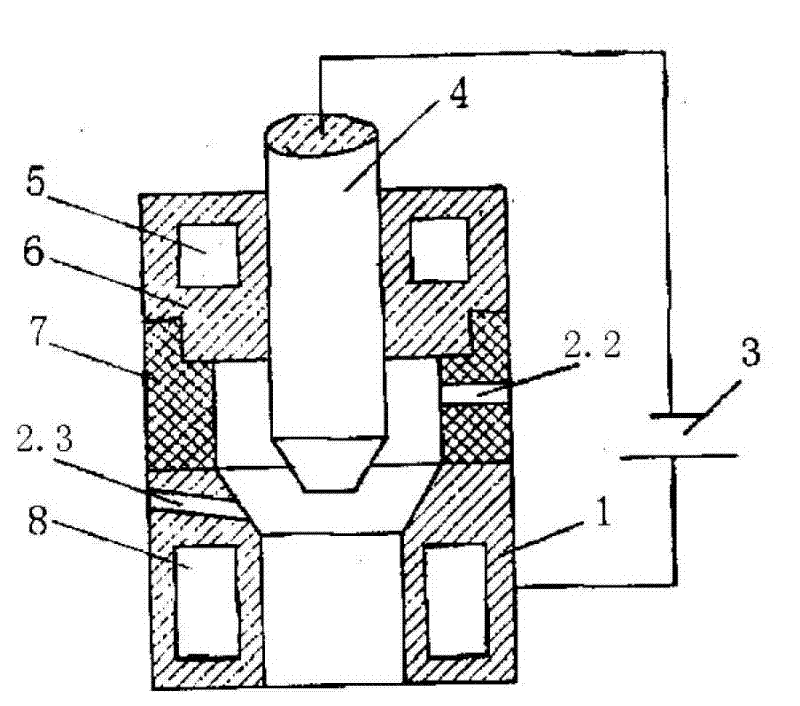

[0022] Start the production of high-purity natural graphite special equipment (see figure 2 ), nitrogen gas pressure: 0.8MPa, powder feeding volume 145g / min, cooling water flow rate: 1.45M / s, using 80KW plasma generator, adjust its working current 60-75A, working voltage: 50-80V, so that the plasma generator A high temperature zone of 3600-4000°C is generated between the cathode and anode. The gas channel 2.2 is still at the position of the insulator 7, and the powder channel 2.3 is opened in the trapezoidal opening section on the upper part of the anode 1; the inner diameters of the gas and powder channels are both 10 mm, and the natural graphite powder is carried by the inert gas argon into the plasma generator, and the natural graphite powder is passed through When the high temperature range of 3600-4000°C generated by the cathode and anode of the plasma generator makes all the ash in the graphite (mainly containing SiO 2 、A1 2 o 3 , Fe 2 o 3 , CaO, MgO) gasification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com