Pulping and papermaking wastewater processing technology

A technology for pulping and papermaking and wastewater treatment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. At the same time, it significantly improves the problems such as reducing the COD value and chromaticity, reducing the processing cost, and improving the processing capacity and buffering capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The COD of pulping and papermaking wastewater is 1630.58mg / L, the chroma is 754.85mg / L, the B / C ratio is 0.28, and the color is yellowish brown.

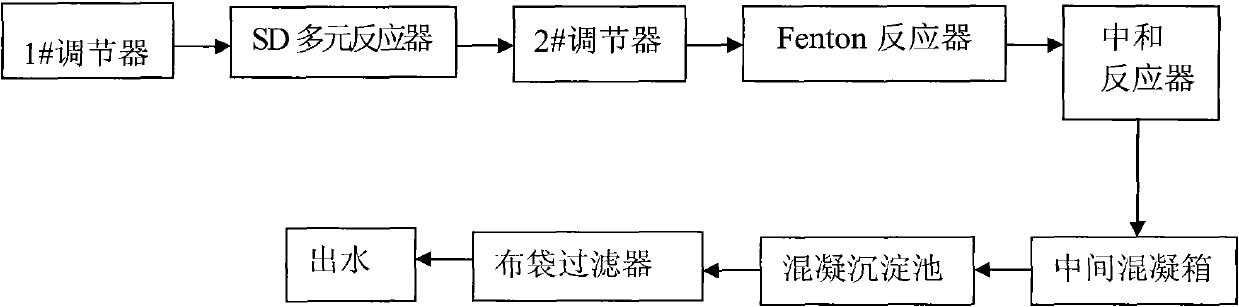

[0034] Pulp and paper wastewater treatment process (see attached figure 1 ):

[0035] (1) Add concentrated sulfuric acid to the 1# adjustment tank of the pulping and papermaking wastewater to adjust the pH value to 3.0-4.0;

[0036] (2) Pour the acidified waste water into the SD multi-component reactor through a water pump to carry out iron-carbon reaction, the iron-carbon mass ratio is controlled to be 3:1, and the reaction time is 60min;

[0037] (3) The waste water after the iron-carbon reaction is discharged into the 2# regulator, and concentrated sulfuric acid is added to adjust the pH to 3.0 to 4.0 again;

[0038] (4) The acidified waste water is discharged into the Fenton reactor, and the H concentration of 1mL / L is added. 2 o 2 Carry out Fenton reaction, reaction time is 60min;

[0039] (5) The waste water after ...

Embodiment 2

[0045] The COD of pulping and papermaking wastewater is 1630.58mg / L, the chroma is 754.85mg / L, the B / C ratio is 0.28, and the color is yellowish brown.

[0046] Pulp and paper wastewater treatment process:

[0047] (1) Add concentrated sulfuric acid to the 1# adjustment tank of the pulping and papermaking wastewater to adjust the pH value to 3.0-4.0;

[0048] (2) Pour the acidified waste water into the SD multi-component reactor through the water pump to carry out the iron-carbon reaction, the iron-carbon mass ratio is controlled to be 2: 1, and the reaction time is 90min;

[0049] (3) The waste water after the iron-carbon reaction is discharged into the 2# regulator, and concentrated nitric acid is added to carry out the pH adjustment again to a pH value of 3.0 to 4.0;

[0050] (4) The waste water after acidifying again is discharged into the Fenton reactor, and the concentration of adding H is 6mL / L 2 o 2 , carry out Fenton reaction, reaction time is 60min;

[0051] (5) ...

Embodiment 3

[0057] The COD of pulping and papermaking wastewater is 1577.49mg / L, the chroma is 673.28mg / L, the B / C ratio is 0.28, and the color is yellowish brown.

[0058] Pulp and paper wastewater treatment process:

[0059] (1) Add concentrated sulfuric acid to the 1# adjustment tank of the pulping and papermaking wastewater to adjust the pH value to 3.0-4.0;

[0060] (2) Pour the acidified waste water into the SD multi-component reactor through a water pump to carry out iron-carbon reaction, the iron-carbon mass ratio is controlled to be 5:1, and the reaction time is 30min;

[0061] (3) The waste water after the iron-carbon reaction is discharged into the 2# regulator, and concentrated hydrochloric acid is added to carry out the pH adjustment again to a pH value of 3.0 to 4.0;

[0062] (4) The waste water after acidifying again is discharged in the Fenton reactor, and adding concentration is the H of 2mL / L 2 o 2 , carry out Fenton reaction, reaction time is 120min;

[0063] (5) Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com