Method for crystallizing milrinone

A milrinone and crystallization technology, applied in the direction of organic chemistry, can solve problems such as unsatisfactory effects, achieve the effects of increased yield and purity, simple process, and solvent saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

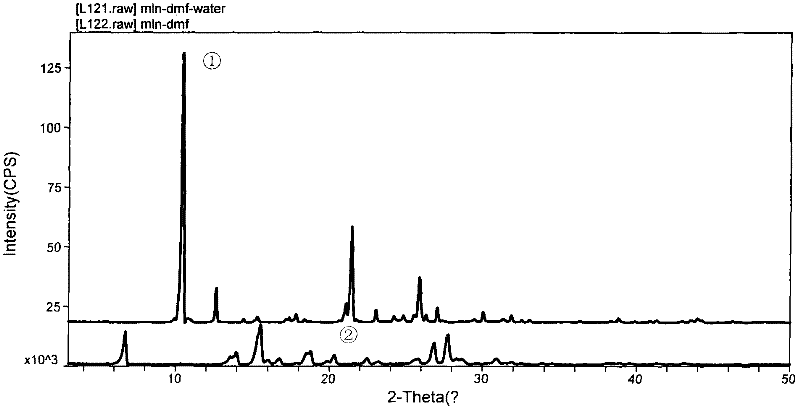

Image

Examples

Embodiment Construction

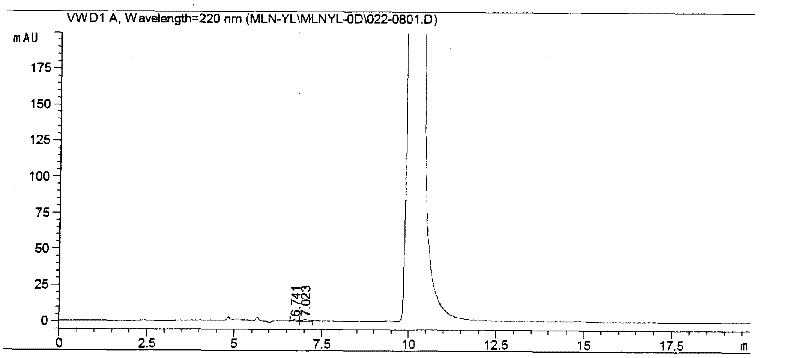

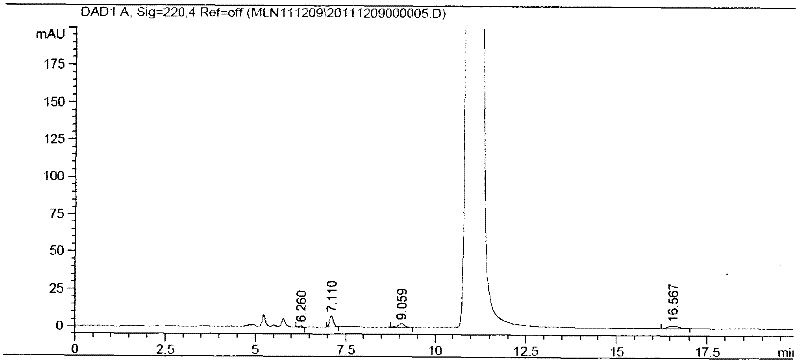

[0013] After the reaction in the last step of milrinone synthesis, add dimethylformamide (DMF) equivalent to 5 to 10 times the volume of milrinone to the crude product of milrinone, slowly heat to dissolve, and then re- Add hot water (60 to 100°C) equal to the volume of dimethylformamide (DMF), preferably 80-95°C, the addition of hot water significantly increases the dissolution rate and solubility of milrinone, and slowly stir to cool down to room temperature Crystals were precipitated, and suction filtration was performed, the filter cake was washed with a small amount of water, and the filter cake was vacuum-dried at 70-80°C to obtain white crystals.

[0014] The temperature of the hot water in the above dissolution process, after long-term practice and exploration by the applicant, is 90°C which is the most suitable. At this time, the dissolution rate increases significantly, which can quickly and fully dissolve milrinone in the solvent to obtain a transparent and clear sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com