Water-soluble electric contact lubricating protective agent improving pluggable resistance of electronic element and use method thereof

A technology for electronic components and protective agents, used in lubricating compositions, petroleum industry, etc., can solve the problems of large surface friction coefficient, low safety factor, easy to absorb dust, etc., to reduce friction coefficient, prolong service life, human body and The effect of environmental safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

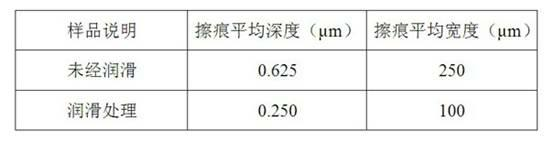

[0034] Example 1 : PCB golden finger insertion force test

[0035] The test sample is a PCB gold finger with a planar structure, and the gold plating thickness is ≥0.30 μm. A total of 2 groups were tested, that is, the control group 1# without lubrication treatment and the test group 2# after lubricating treatment with the water-soluble electrical contact lubricant protection agent provided by the present invention.

[0036] 1#: Blank control group without lubrication treatment.

[0037] 2#: Use the water-soluble electrical contact lubricant protection agent of the present invention for lubrication treatment. The thickness of the film layer is 10~20 nm (5~10 molecular layers).

[0038] The ratio (by weight percentage) of the water-soluble electrical contact lubricant protection agent concentrate used in this embodiment is as follows:

[0039] Stearyl alcohol (stearyl alcohol) 4.5% and cyclohexyl hexaphosphate (phytic acid) 5.5% (molar ratio=2:1);

[0040] Lecithin (Beijin...

Embodiment 2

[0051] Example 2 : Effects of fatty alcohols with different numbers of C atoms on the lubricating properties of electronic components.

[0052] This example investigates the effect of fatty alcohols with different C atom numbers on the lubricating properties of electronic components. Used test sample, test method are exactly the same as embodiment 1. Except for fatty alcohol and phytic acid, the water-soluble electrical contact lubricant protection agent concentrate used in this embodiment, the remaining components and their weight percentages are exactly the same as in Example 1

[0053] The total weight percentage of fatty alcohol and phytic acid is still 10%, and the molar ratio of the two is about 2:1. The weight percentage composition of the two is shown in Table 2.

[0054] Table 2 Effects of fatty alcohols with different numbers of C atoms on the lubricating properties of gold fingers

[0055]

[0056] *Average friction coefficient reduction rate = (average inser...

Embodiment 3

[0059] Example 3 : the influence of the mol ratio of fatty alcohol and phytic acid on the lubricating performance of the present invention.

[0060] When the fatty alcohol has 12-18 carbon atoms, it will work with phytic acid, and the influence on the lubricating performance of the present invention is mainly related to the molar ratio of the two. This example investigates the influence of different molar ratios of fatty alcohol and phytic acid on the lubricating performance of the present invention.

[0061] In this embodiment and all subsequent embodiments, stearyl alcohol is selected as the fatty alcohol used in this patent. The test samples and test methods used in this embodiment are exactly the same as those in Example 1; except for stearyl alcohol and phytic acid, the water-soluble electrical contact lubricant protection agent concentrate used has the same components and their weight percentages as in Example 1. .

[0062] In this embodiment, the total weight percen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com