Immobilized enzyme using modified epoxy resin as carrier and preparation method and application thereof

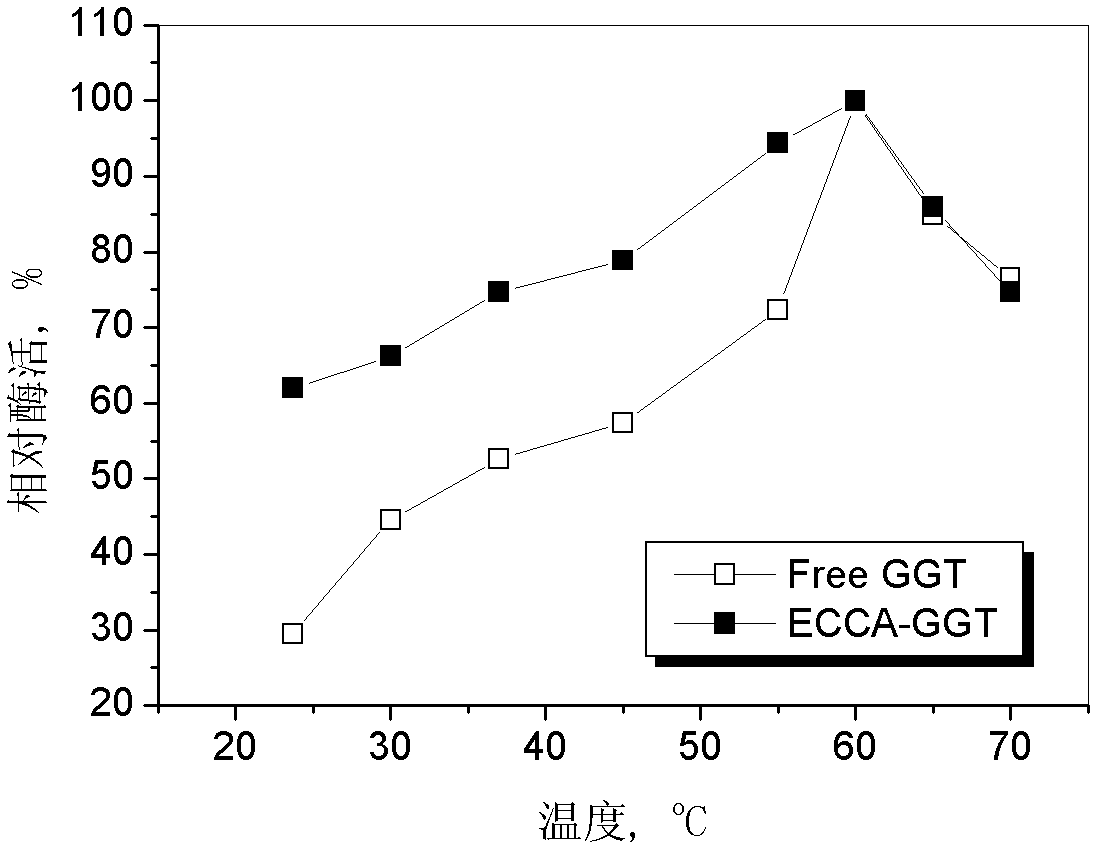

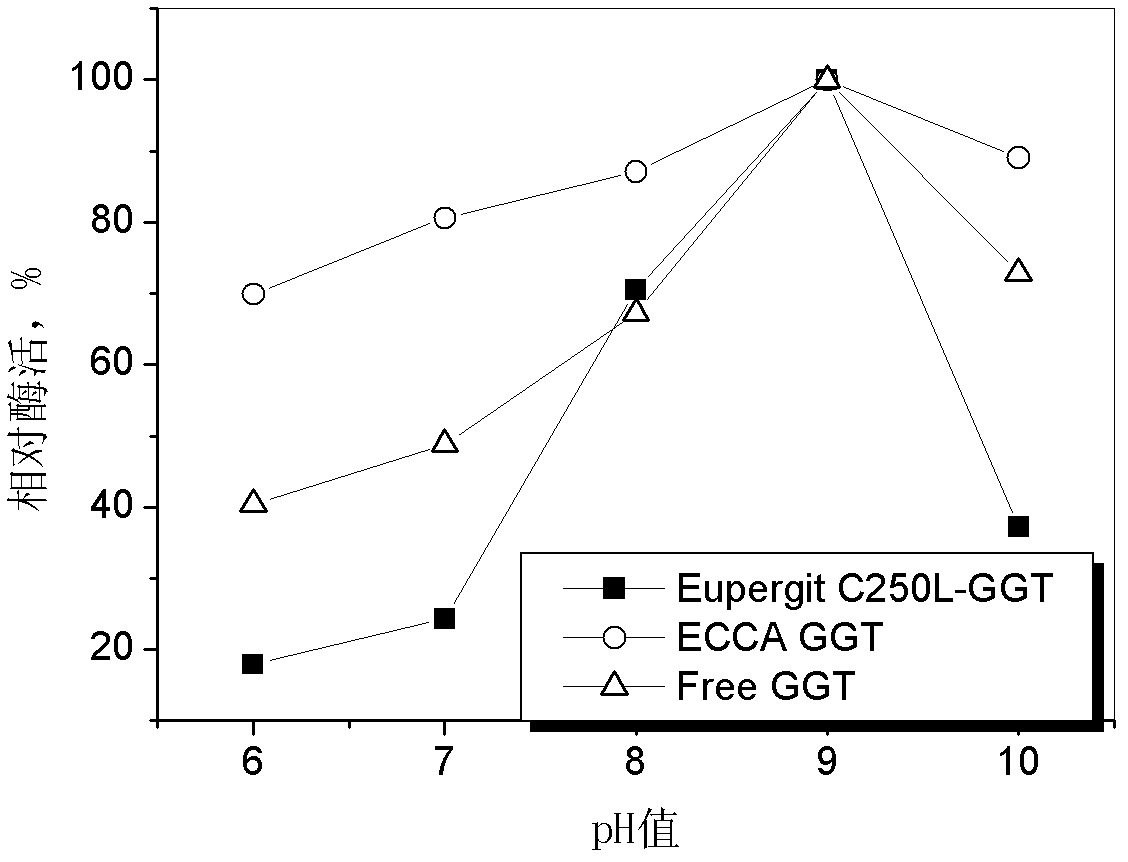

An epoxy-based resin and immobilized enzyme technology, which is applied in the fields of immobilization on/in organic carriers, chemical industry, climate sustainability, etc., can solve the problem of immobilization and stabilization of γ-glutamyl transpeptidase There are few researches, immobilization and application have not been reported, and the expansion of application range is limited, so as to achieve the effect of good reusable performance, uniform shape, and increased applicable pH and temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of ECCA carrier.

[0045] Take 0.3g dried Eupergit C 250L Put it in a 20ml sand core tube, add 50% (v / v) CA aqueous solution according to the solid-to-liquid ratio of 1g / 20mL, and react at room temperature for 16h. After the reaction is completed, the reaction liquid will be filtered out first. The dried solid particles were rinsed repeatedly with pure water for 6 to 7 times; then rinsed with 0.5mol / L NaCl solution for 3 to 4 times; finally rinsed with pure water for 6 to 7 times and then filtered dry. The CA-modified carrier ECCA was obtained by drying at 40°C. The grafted amount of CA calculated by the mass difference method was 0.0964g.

Embodiment 2

[0046] Example 2: Preparation of ECCA carrier.

[0047] Weigh 0.3g of dried Eupergit C 250L Put it in a 20ml sand core tube, add 100% (v / v) CA according to the solid-to-liquid ratio of 1g / 10mL, and react at room temperature at 24°C for 20h. After the reaction, the reaction liquid will be filtered out first. The dried solid particles were rinsed repeatedly with pure water for 6 to 7 times; then rinsed with 0.5mol / L NaCl solution for 3 to 4 times; finally rinsed with pure water for 6 to 7 times and then filtered dry. The CA-modified carrier ECCA was obtained by drying at 40°C. The grafted amount of CA calculated by mass subtraction method was 0.124g.

Embodiment 3

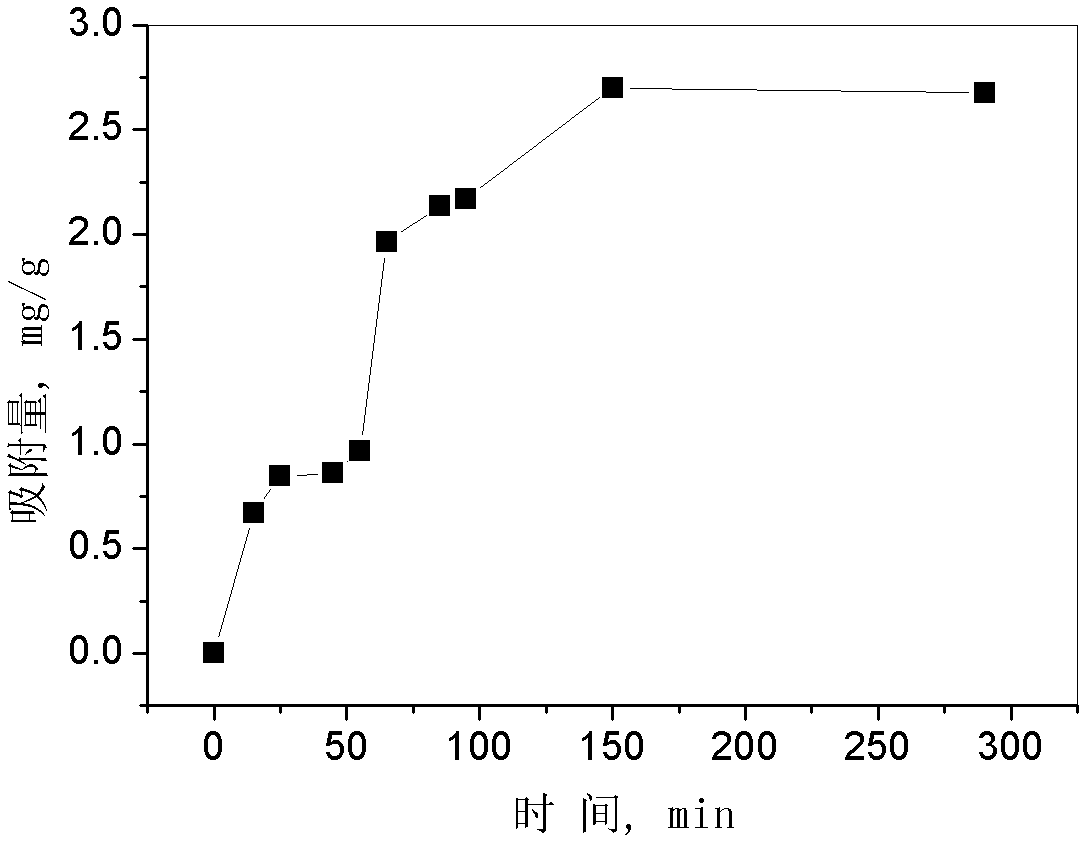

[0048] Example 3: Preparation method of ECCA-GGT.

[0049] Take by weighing 0.3g of the dry product carrier ECCA prepared by the most preferred method in Example 2 and put it in the ampoule bottle, add the purified GGT enzyme solution (enzyme concentration is 0.3mg / mL) according to the solid-liquid ratio 1g: 13.3mL, and in Shake the reaction in a water bath at room temperature for 1 hour. After the reaction, the reaction liquid is filtered out, and the filtered solid particles are repeatedly rinsed with pure water for 3 to 4 times, and dried at 30°C to obtain ECCA-GGT. The adsorption capacity of GGT was 1.26mg / g resin, and the recovery rate of enzyme activity was 9.72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com