Solution and method for preparing nano-pore arrays on surfaces of silicon chip

A nanopore array, silicon wafer surface technology, applied in anodizing and other directions, can solve problems such as legal restrictions on development, and achieve the effect of improving conversion efficiency, simplifying processing procedures, and good environmental compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

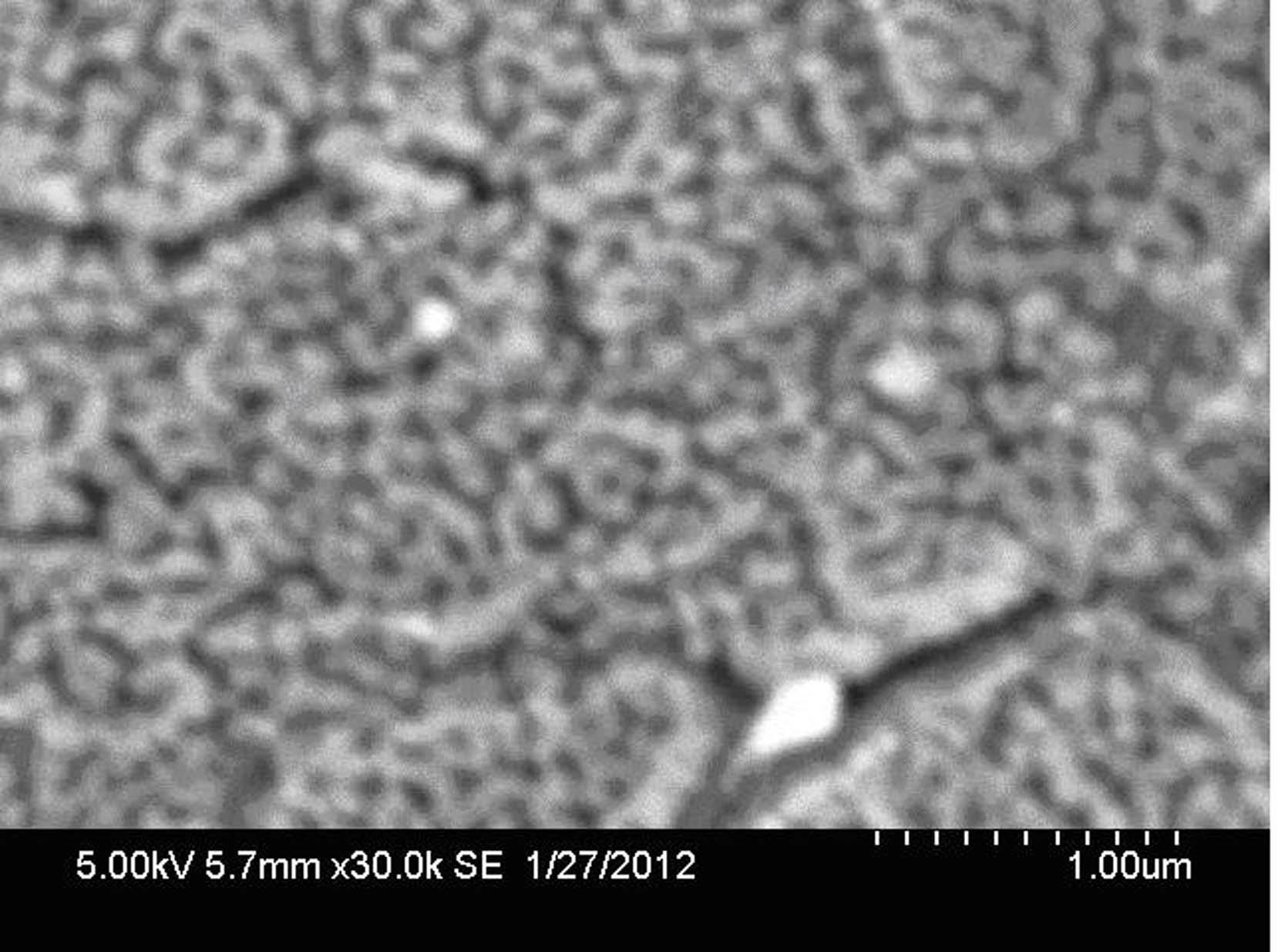

Image

Examples

Embodiment 1

[0011] Embodiment 1: Add 56g oxalic acid, 44mL glycerin solution in 1L deionized water, take silicon chip as anode, stainless steel as cathode, process under 45V voltage for 4 hours, the aperture of its nanopore is less than 500nm, illustrate that processing can obviously reduce Wafer processing costs.

Embodiment 2

[0012] Example 2: First, take 2 / 3 of deionized water in a 10L tank, add 560g of oxalic acid and 810mL of glycerol in turn under stirring, and finally add water to 10L to obtain an electrolyte, with a silicon chip as the anode and a stainless steel as the cathode , treated at a voltage of 60V for 5 hours, the diameter of the nanopores is less than 800nm.

Embodiment 3

[0013] Embodiment 3: first take 2 / 3 deionized water in a 10L tank, add 700mL of phosphoric acid and 1200mL of ethanol with a concentration of 85% successively under stirring, finally add water to 10L, obtain electrolyte, use silicon chip as anode, The stainless steel is used as the cathode, and it is treated at 40V for 2 hours, and the diameter of the nanopores is less than 600nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com