Method for improving recovery ratio of normal heavy oil reservoirs in water-flooding development

A technology for heavy oil reservoirs and recovery factors, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. The problem of high viscosity of the movable gel system can reduce the permeability of water phase, expand the swept volume of water flooding, and improve oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

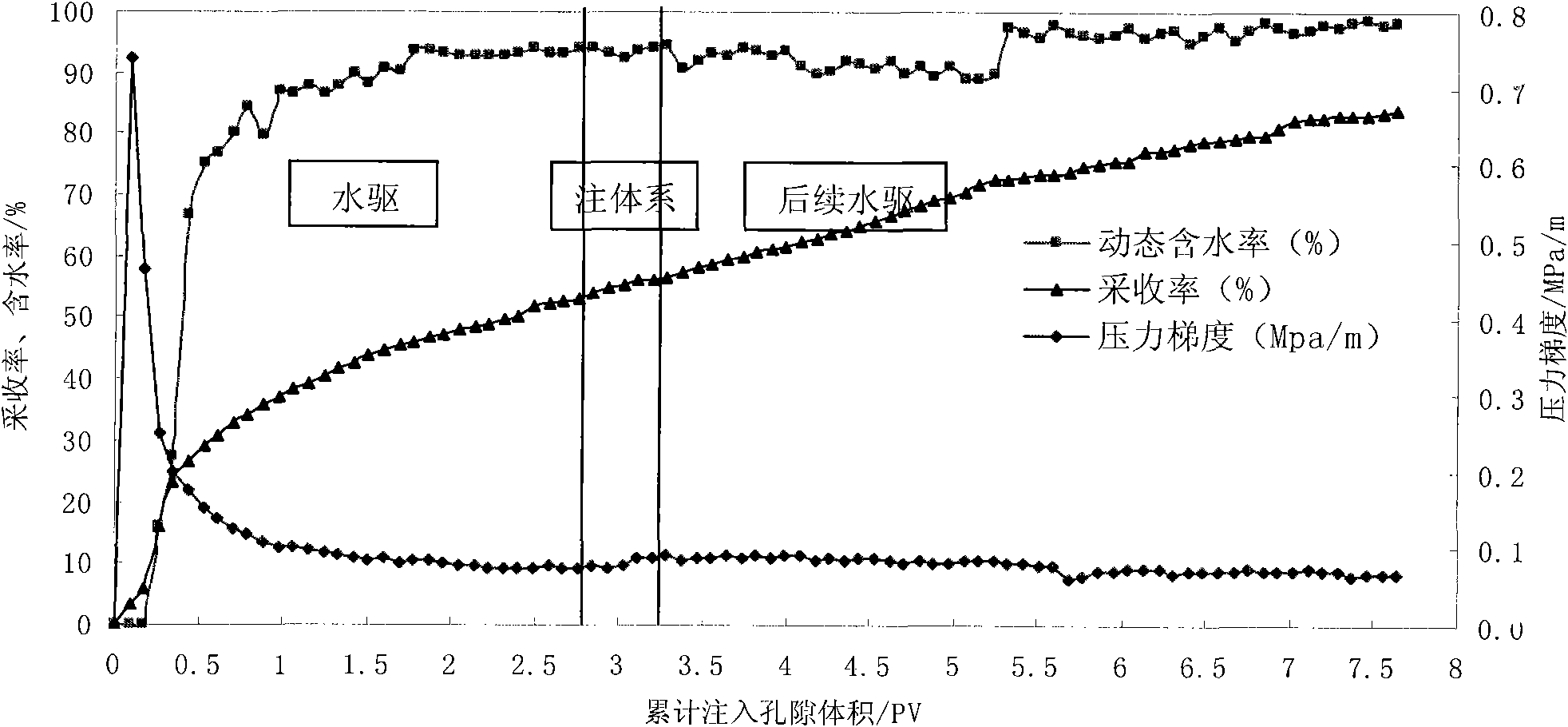

[0036] Example 1: Core flooding experiment of composite microgel control and flooding system with non-uniform man-made sand-packed pipe

[0037] Experimental conditions:

[0038] Parallel cores with non-average man-made sand-fill pipes: the permeability is 3370md and 480md respectively.

[0039] Experimental oil: degassed and dehydrated crude oil taken from Block 1 of Liaohe Oilfield, with a viscosity of 75.0 mPa s at 70°C.

[0040] Experimental water: simulated water taken from the sewage of Liaohe Oilfield Hai 4 station for liquid preparation, with a salinity of 2286.5mg / L

[0041] Composite flood control agent: 1000mg / l movable microgel (produced by Beijing Shida Wanjia Energy and Environmental Technology Co., Ltd.), 3000mg / l sodium dodecylbenzenesulfonate surfactant (ORS series of products) mixed compound system.

[0042] Experimental temperature: 70°C

[0043] Experimental steps:

[0044] (1) Evacuate the physical model for 4-5 hours, then saturate the simulated form...

Embodiment 2

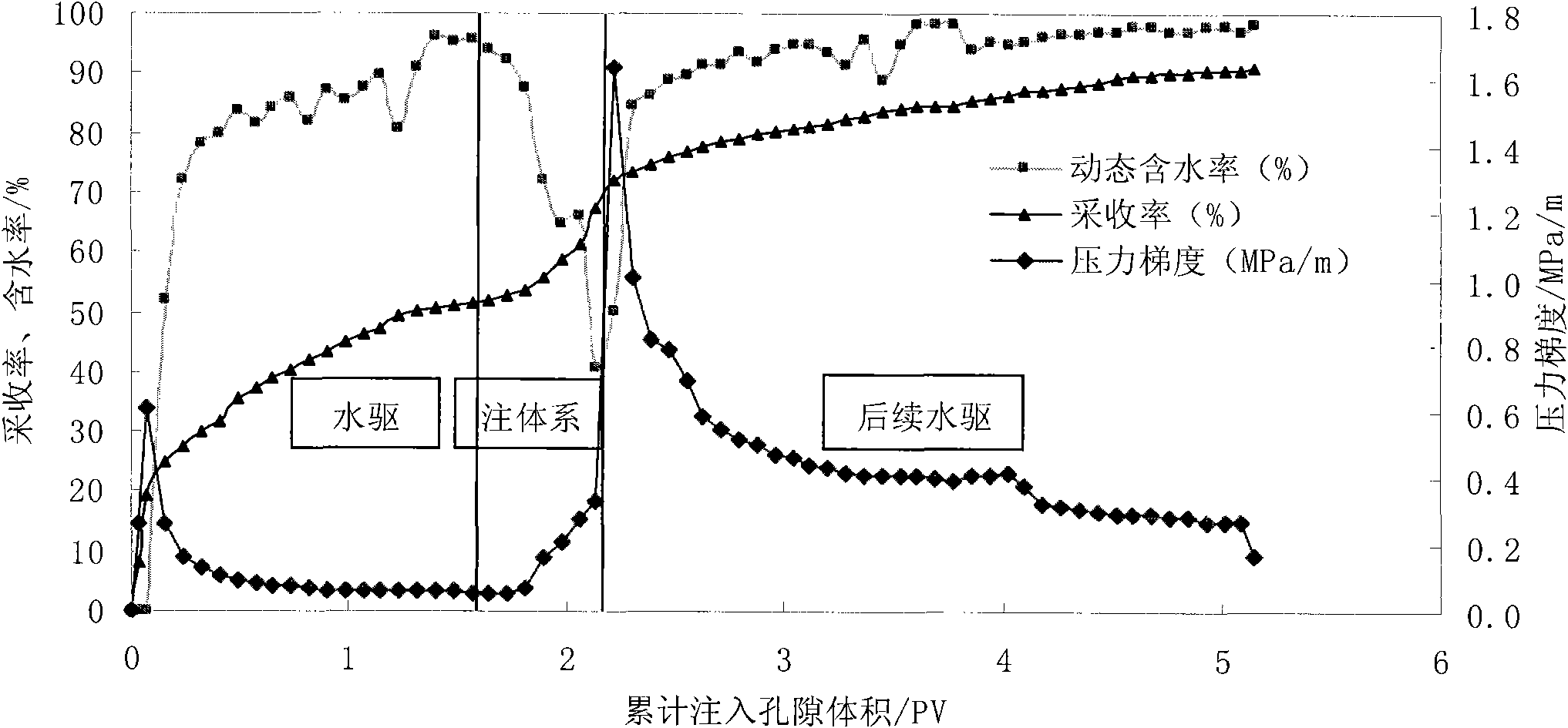

[0053]Example 2: Core flooding experiment of composite microgel control and flooding system with non-uniform man-made sand-packed pipe

[0054] Experimental conditions:

[0055] Parallel cores with non-average man-made sand-fill pipes: the permeability is 2810md and 510md respectively.

[0056] Experimental oil: degassed and dehydrated crude oil taken from Block 1 of Liaohe Oilfield, with a viscosity of 75.0 mPa s at 70°C.

[0057] Experimental water: simulated water taken from the sewage of Liaohe Oilfield Hai 4 station for liquid preparation, with a salinity of 2286.5mg / L

[0058] Composite flood control agent: 1000mg / l movable microgel (produced by Beijing Shida Wanjia Energy and Environmental Technology Co., Ltd.), 3000mg / l ammonium dodecylbenzenesulfonate surfactant (ORS series of products) mixed compound system.

[0059] Experimental temperature: 70°C

[0060] Experimental steps:

[0061] (1) Evacuate the physical model for 4-5 hours, then saturate the simulated for...

Embodiment 3

[0070] Example 3: Field Implementation of Composite Microgel Control and Flood System

[0071] (1) First, the submillimeter-scale movable microgel is pumped into the water injection pipeline through a well pump, and configured as a pre-blocking slug with a concentration of 1000 mg / l, and the injection volume is 0.08 times the pore volume of the oil layer.

[0072] (2) Then mix the micron-scale movable microgel and surfactant according to the ratio of 4:1, pump it into the water injection pipeline through the well pump, and configure it as a main slug for regulating and driving with a concentration of 2000mg / l, and the injection volume is 0.1 times Oil layer pore volume.

[0073] (3) Finally, the submillimeter-scale movable microgel is pumped into the water injection pipeline through the well pump, configured as a post-sealing slug with a concentration of 1000 mg / l, and the injection volume is 0.02 times the pore volume of the oil layer.

[0074] The microgel in this embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com