Positive photosensitive resin composite and method for forming pattern

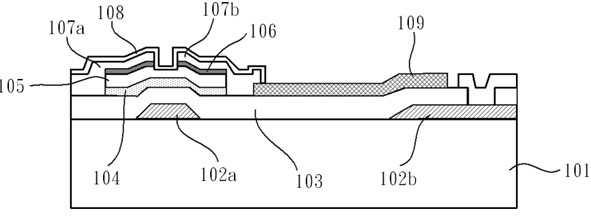

A technology of photosensitive resin and composition, which is applied in the photoplate-making process of patterned surface, optics, optomechanical equipment, etc. It can solve the problems of poor crack resistance, poor heat resistance, and failure to meet standards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

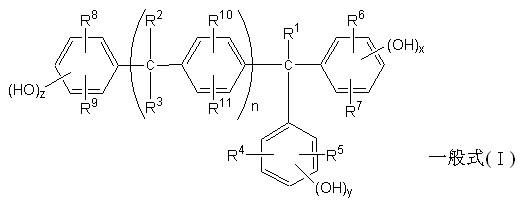

Synthetic example 1

[0088] On a four-necked conical flask with a capacity of 1000 milliliters, a nitrogen inlet, a stirrer, a heater, a condenser tube and a thermometer are set, and after introducing nitrogen, 64.89 g (0.6 mol) of m-cresol and 43.26 g (0.4 mol) of p-cresol are added. ), 55.25 g (0.4 mol) of 3,4-dihydroxybenzaldehyde and 1.80 g (0.02 mol) of oxalic acid. The temperature of the reaction solution was raised to 100°C with slow stirring, and polymerized at this temperature for 5 hours. Then, the temperature of the reaction solution was raised to 180° C., and the pressure of 10 mmHg was used for drying under reduced pressure. After the solvent was devolatilized, the hydroxyl-type novolac resin (A-1-1) was obtained.

Synthetic example 2

[0090] The hydroxy-type novolac resin (A-1-2) was prepared in the same steps as in Synthesis Example 1 above, except that 48.85 g (0.4 mol) of o-hydroxybenzaldehyde was used to replace 3,4-dihydroxybenzaldehyde.

Synthetic example 3

[0092] Hydroxy-type novolac resin (A-1-3) was prepared in the same steps as in Synthesis Example 1 above, except that 61.65 g (0.4 moles) of 2,3,4-trihydroxybenzaldehyde was used to replace 3,4-dihydroxy Benzaldehyde.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com