Mercury-free zinc paste of button alkaline zinc-manganese dioxide cell and preparation method for mercury-free zinc paste

A zinc-manganese battery and zinc paste technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as high cost and environmental pollution, and achieve the effects of cost reduction, simple formula, and favorable battery storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1). Take 90kg of potassium hydroxide, 15kg of zinc oxide, and 95kg of pure water. First, pour 95kg of pure water into the preparation tank. Under stirring, add 90kg of potassium hydroxide into the preparation tank and let it dissolve. Add 15kg of zinc oxide into the preparation tank while it is hot under stirring, let it dissolve, filter it with a filter element with a pore size of 1 μm after cooling, and then adjust the filtered electrolyte to a potassium hydroxide concentration of 42.5%, i.e. get electrolyte;

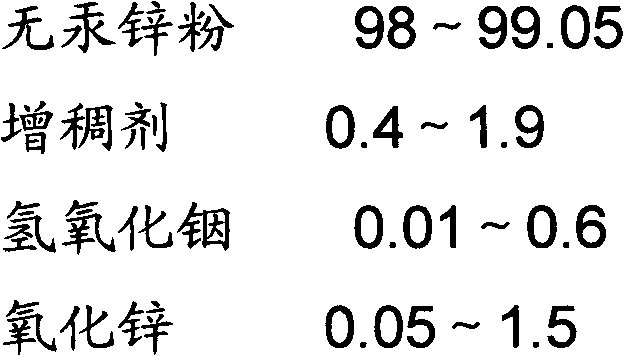

[0024] (2) Take 9,810g of mercury-free zinc powder, 60g of sodium carboxymethyl cellulose, 30g of sodium polyacrylate, 10g of indium hydroxide, and 90g of zinc oxide. After weighing each material, pour them into the agate of the three-dimensional ball mill mixing equipment Grind in the cup, start mixing for 30 minutes, slowly add 4kg of the above electrolyte into the mixing cup, vacuumize to below 1 kPa after adding, grind for 45 minutes, stop stirring, open t...

Embodiment 2

[0028] (1) Get 90kg potassium hydroxide, 15kg zinc oxide, 93kg pure water, pour 93kg pure water into the preparation tank earlier, under the state of stirring, add 90kg potassium hydroxide in the preparation tank, allow it to dissolve, then in While stirring, add 15kg of zinc oxide to the preparation tank to dissolve it while it is hot. After cooling, filter it with a filter element with a pore size of 1 μm, and then add pure water to the filtered electrolyte to adjust the concentration of potassium hydroxide to 32.5%. liquid;

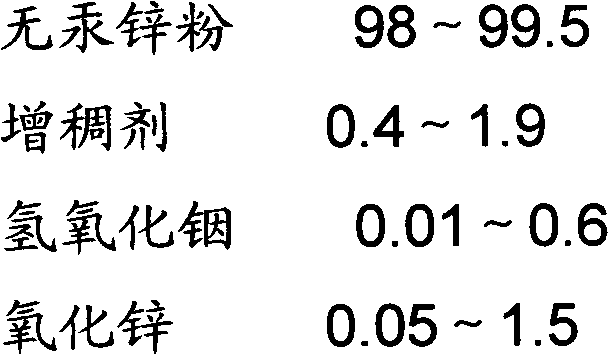

[0029] (2) Take 9.800kg of mercury-free zinc powder, 65g of sodium carboxymethylcellulose (FH9), 35g of sodium polyacrylate, 40g of indium hydroxide, and 60g of zinc oxide. After weighing each material, pour them into the three-dimensional ball mill mixture Grind in the agate cup of the equipment, start mixing for 25 minutes, slowly add 2kg of the above electrolyte into the mixing cup, vacuumize to below 1 kPa after adding, grind for 60 minutes, stop s...

Embodiment 3

[0032] (1). Take 90kg of potassium hydroxide, 15kg of zinc oxide, and 95kg of pure water. First, pour 95kg of pure water into the preparation tank. Under stirring, add 90kg of potassium hydroxide into the preparation tank and let it dissolve. Add 15kg of zinc oxide into the preparation tank while it is hot under stirring, let it dissolve, filter it with a filter element with a pore size of 1 μm after cooling, and then adjust the filtered electrolyte to a potassium hydroxide concentration of 42.5%, i.e. get electrolyte;

[0033] (2) Take 9,820g of zinc powder containing 1.5% mercury, 60g of polyacrylate, 30g of sodium polyacrylate, and 90g of zinc oxide. After weighing each material, pour them into the agate cup of the three-dimensional ball mill mixing equipment for grinding, and turn on Mix for 30 minutes, slowly add 4kg of the above electrolyte into the mixing cup, vacuumize to below 1 kPa after adding, grind for 45 minutes, stop stirring, open the air valve, take out the zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com