Improved diesel oxidation catalytic converter

A technology of catalyst and catalytic activity, which is applied in the field of oxidation catalyst and exhaust gas purification of heavy-duty trucks. It can solve the problem that the catalyst does not show NO-oxidation activity, and achieve the effect of improving heating-performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

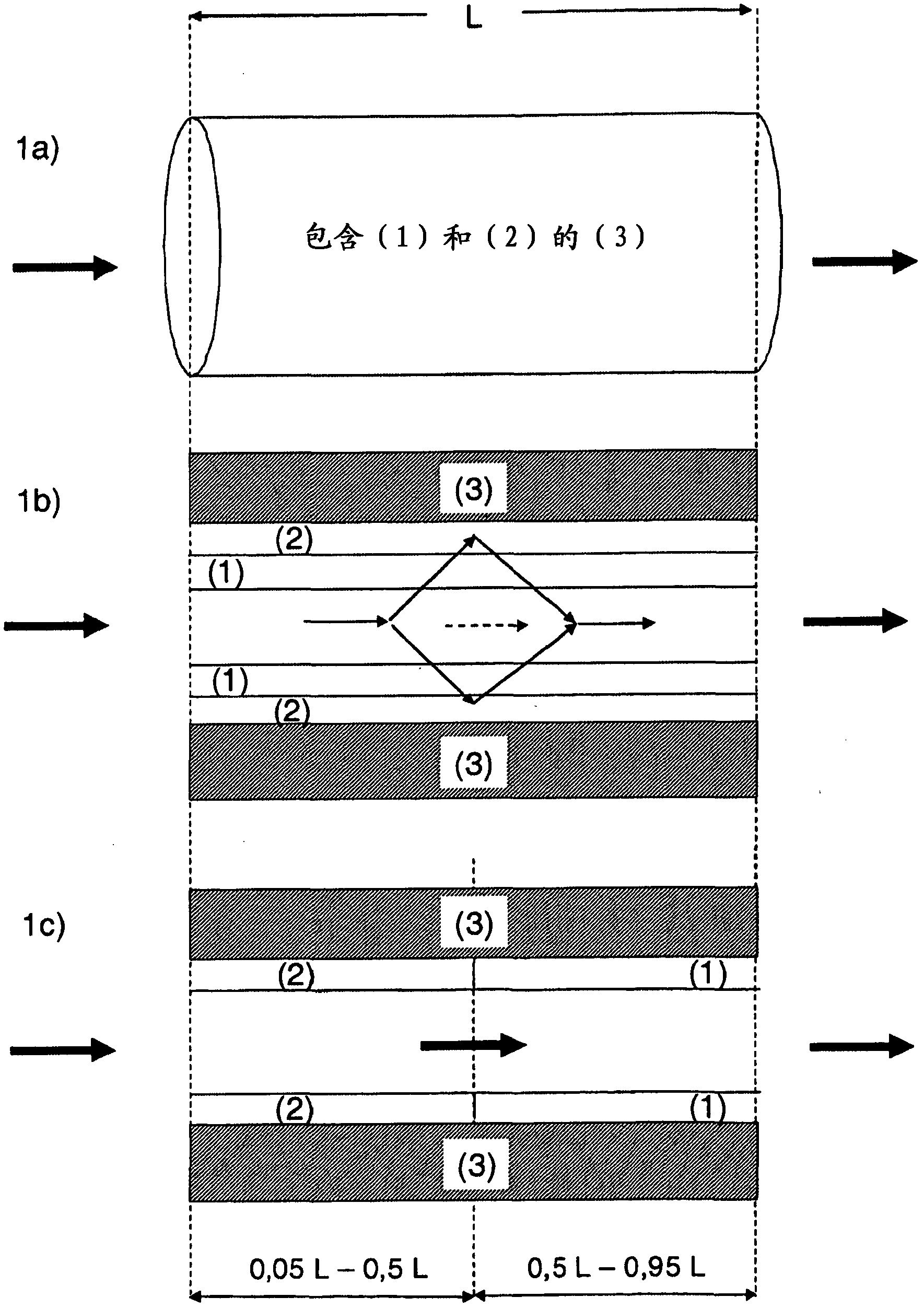

Method used

Image

Examples

Embodiment 1

[0063] A catalyst according to the invention was prepared whose total noble metal content and platinum-palladium ratio corresponded to the conventional diesel oxidation catalyst of Comparative Example 1.

[0064] To this end, a first coating is first applied to the ceramic honeycomb body, which has the following composition, based on the volume of the catalyst produced:

[0065] 40g / L silicon-aluminum-mixed oxide containing up to 20% by weight SiO 2

[0066] 0.204g / L precursor platinum nitrate solution

[0067] 0.204g / L precursor palladium nitrate solution

[0068] 15 g / L commercially available beta-zeolite

[0069] The coating represents a coating that does not come into direct contact with the exhaust gases after the catalyst has been produced.

[0070] After drying and calcination of the first layer, a second layer was applied thereon, having the following composition based on the volume of the catalyst produced:

[0071] 40g / L silicon-aluminum-mixed oxide containing u...

Embodiment 2

[0096] Corresponding to the procedure described in Example 1, the catalyst K2 according to the invention was prepared with two superimposed layers of the following composition:

[0097] 1st layer = lower layer = coating not in direct contact with exhaust gases:

[0098] 92g / L silicon-aluminum-mixed oxide containing up to 20% by weight SiO 2

[0099] 0.302g / L precursor platinum nitrate solution

[0100]0.302g / L precursor palladium nitrate solution

[0101] Layer 2 = upper layer = coating in direct contact with exhaust gases:

[0102] 45g / L silicon-aluminum-mixed oxide containing up to 20% by weight SiO 2

[0103] 0.706g / L precursor platinum nitrate solution

[0104] 0.101g / L precursor palladium nitrate solution

Embodiment 3

[0106] Corresponding to the procedure described in Example 1, the catalyst K2 according to the invention was prepared with two superimposed layers of the following composition:

[0107] 1st layer = lower layer = coating not in direct contact with exhaust gases:

[0108] 40g / L silicon-aluminum-mixed oxide containing up to 20% by weight SiO 2

[0109] 0.303g / L precursor platinum nitrate solution

[0110] 0.303g / L precursor palladium nitrate solution

[0111] 15 g / L commercially available beta-zeolite

[0112] Layer 2 = upper layer = coating in direct contact with exhaust gases:

[0113] 45g / L silicon-aluminum-mixed oxide containing up to 20% by weight SiO 2

[0114] 0.706g / L precursor platinum nitrate solution

[0115] 0.101g / L precursor palladium nitrate solution

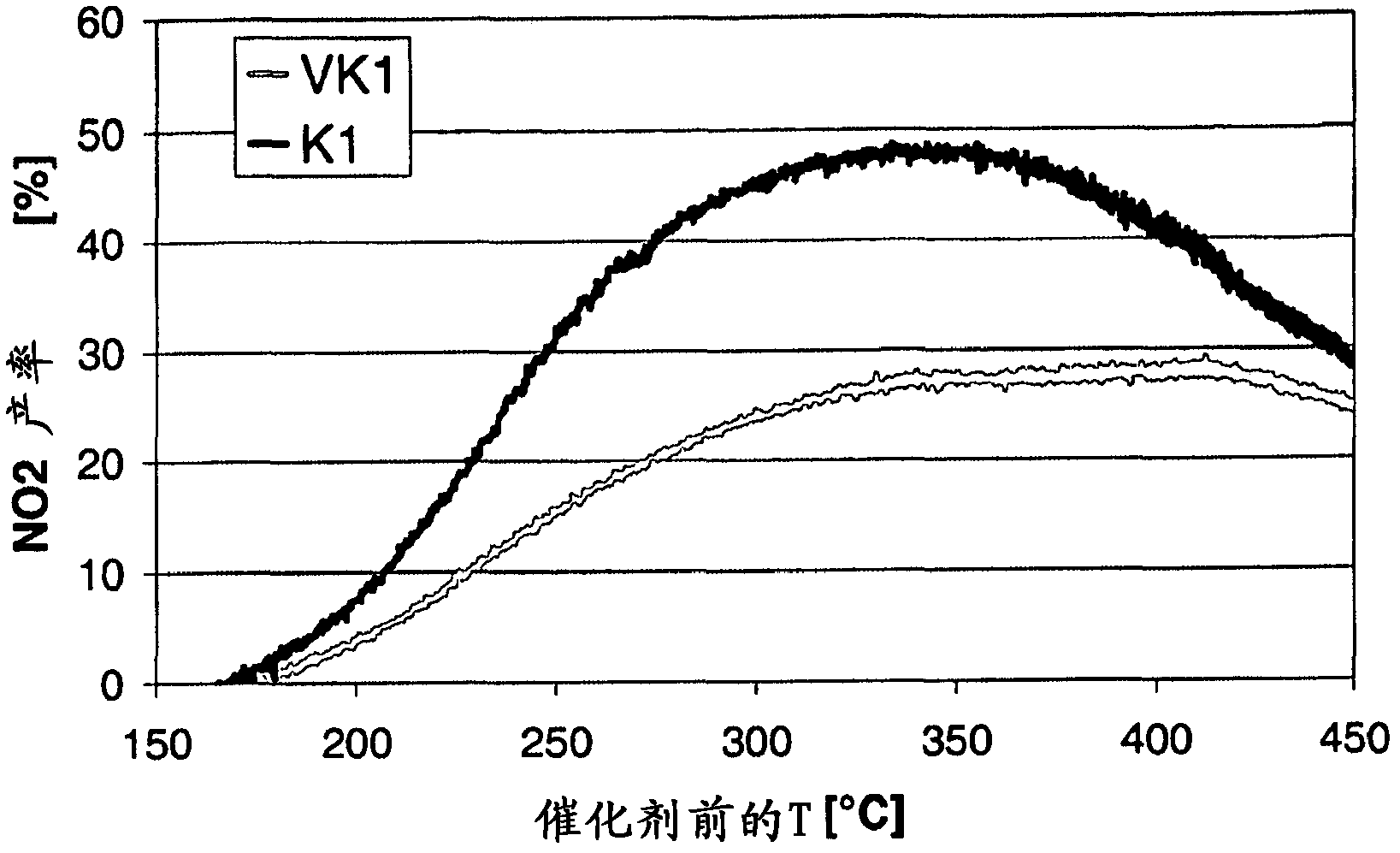

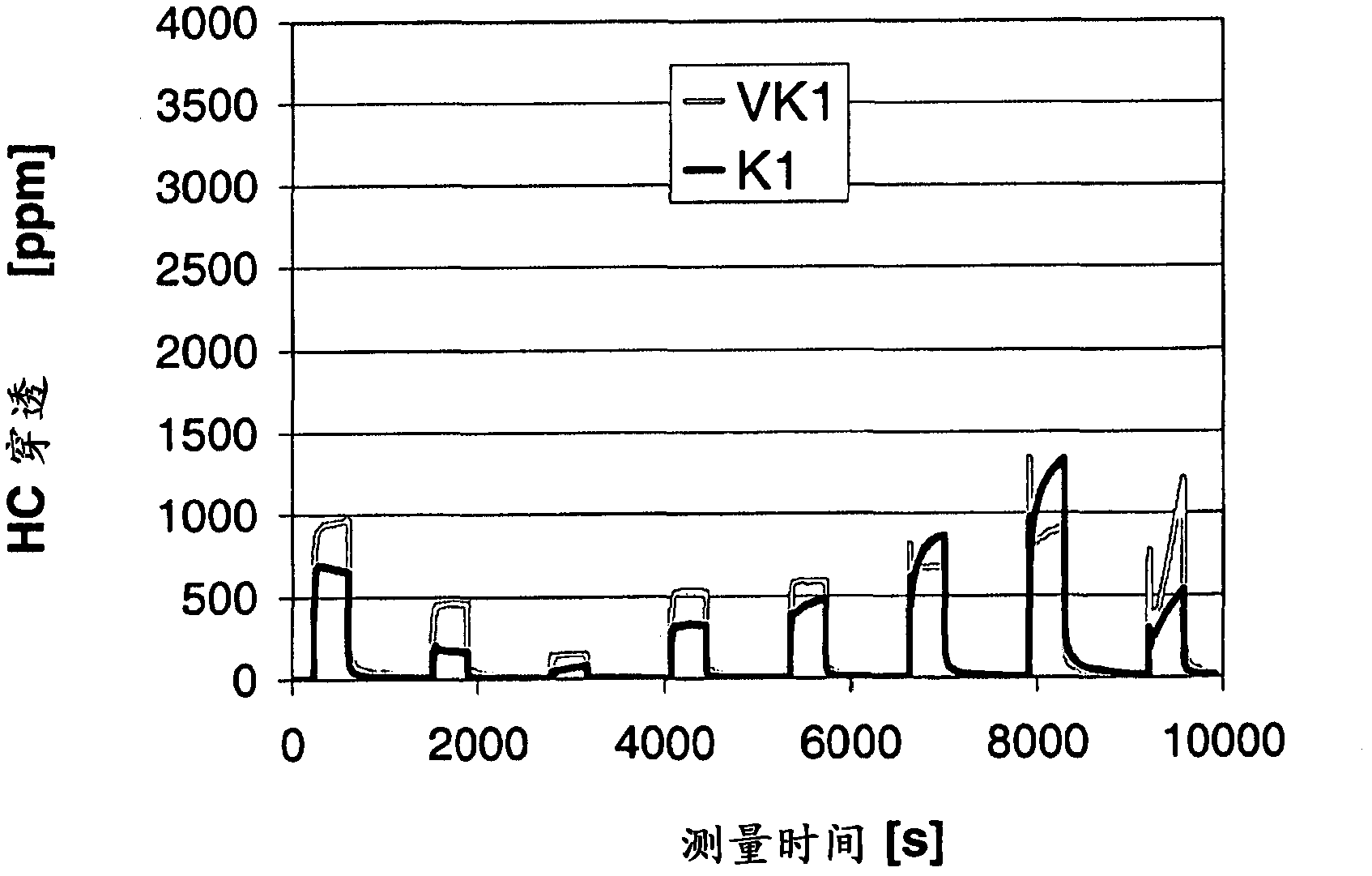

[0116] Figure 6 shows that the addition of zeolite to the coating not in direct contact with the exhaust gas has an effect on the NO of the catalyst 2 - Yield was not significantly affected.

[0117] Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com