Process for synthesis of polyalphaolefin

A technology for olefins and olefin monomers, which is applied in chemical instruments and methods, hydrocarbons, lubricating compositions, etc., and can solve the problems of wasting water and complicated washing methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

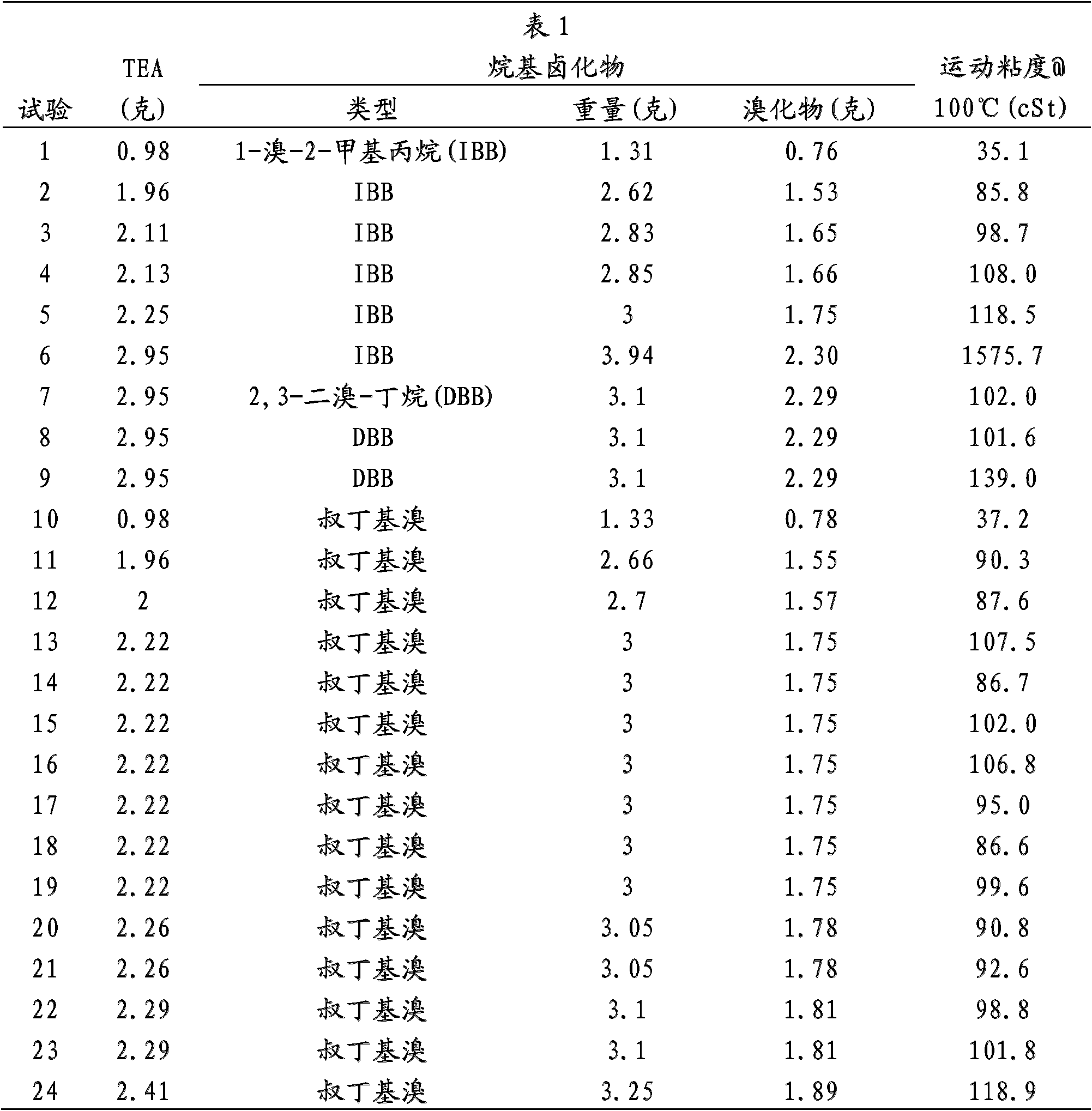

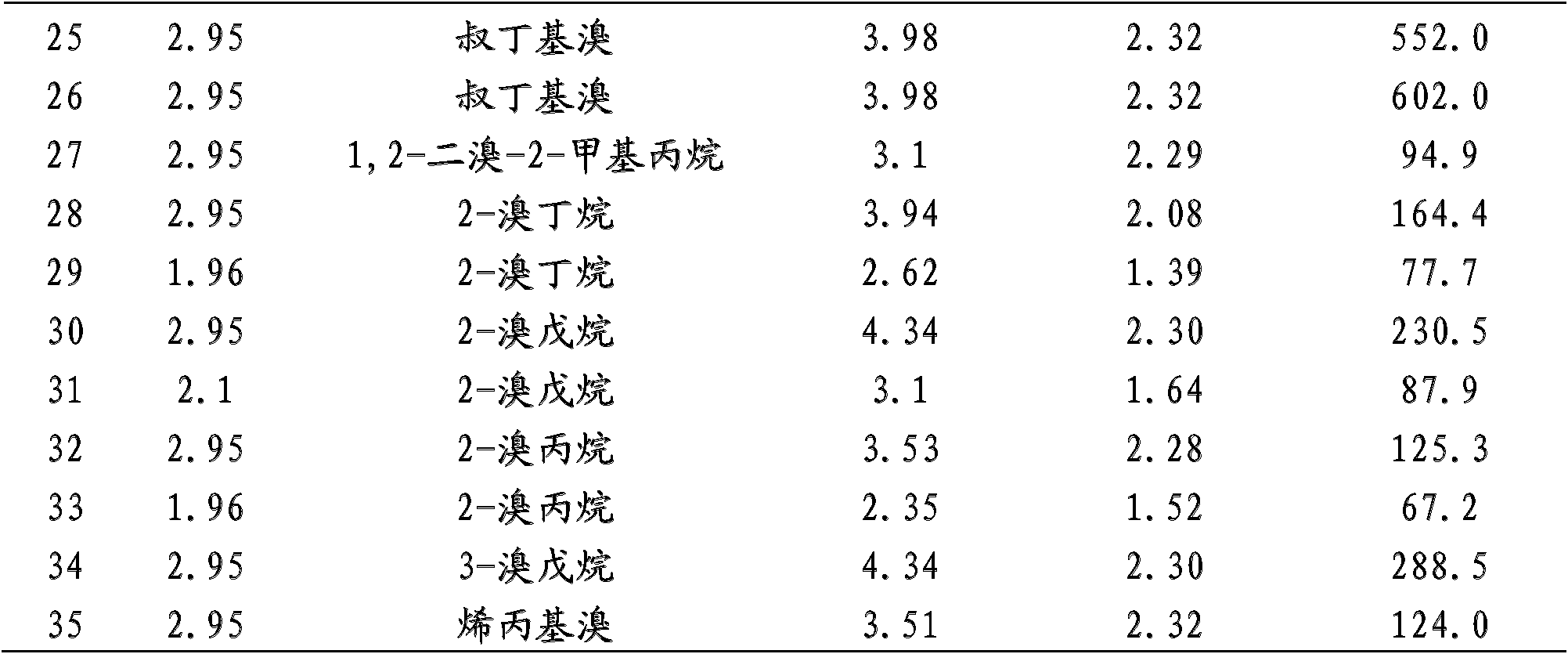

Embodiment 1

[0035] Polymerization of 1-decene in a continuous reactor. The reaction temperature was 40°C and the residence time was 2.8 hours. The mixed feed rate of TEA prediluted in decene and alkyl halide prediluted in decene was 6.0 g / min. The TEA used was a solution containing 25 wt% TEA and 75% decene. The molar ratio of bromide to aluminum for each run 1-37 in Table 1 was 3.3:1 and the weight amounts indicated in Table 1 were used. The gram numbers provided in Table 1 are based on 100 grams of decene. Table 1 shows the viscosities of the PAO products produced.

[0036]

[0037]

[0038] Trials 1-6 correspond to exemplary embodiments of the present invention. In comparing the amount of bromide equivalents from Run 6 with Runs 7, 8, 9, 24, 25, 27, 30, 32, 34 and 36, Run 6 surprisingly and unexpectedly produced greater Viscosity of any one of tests 7, 8, 9, 24, 25, 27, 30, 32, 34 and 36 of halides. Thus, 1-halo-2-methylpropanes, such as 1-bromo-2-alkylpropanes (IBB), use l...

Embodiment 2

[0040] 150 g of crude polydecene material prepared according to Experiment 5 was diluted with 50 g of decene and treated with 5 g of CaO (20 mesh) in a beaker with magnetic stirring at 50° C. for 15 minutes. The crude material was filtered with a 10 micron asbestos pressure filter using 20-80 psi nitrogen pressure to reduce the levels of aluminum and bromine in the polydecene material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com