Capsaicin functional-group containing hydrophilic anti-biological-contamination ultrafiltration membrane and preparation method thereof

An anti-biological fouling and functional group technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane separation performance degradation, ultrafiltration membrane surface biofouling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

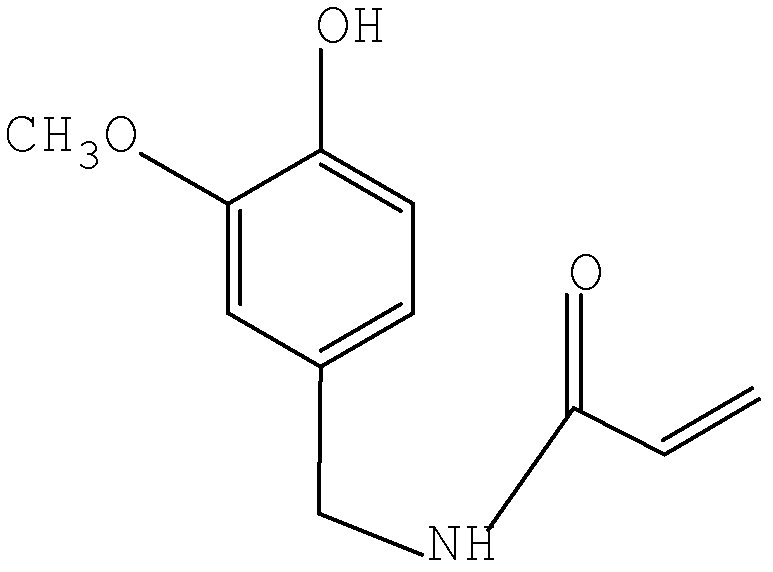

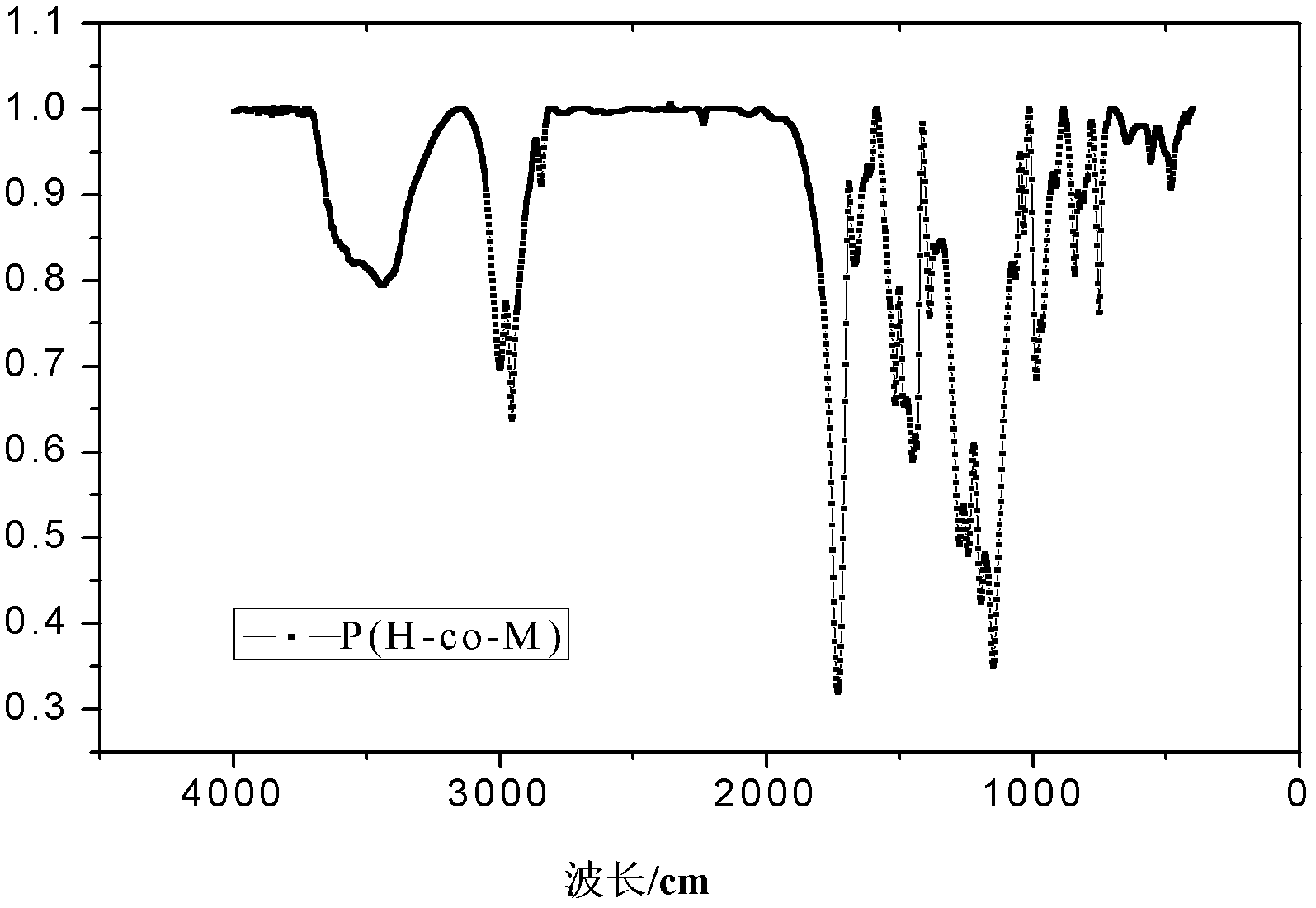

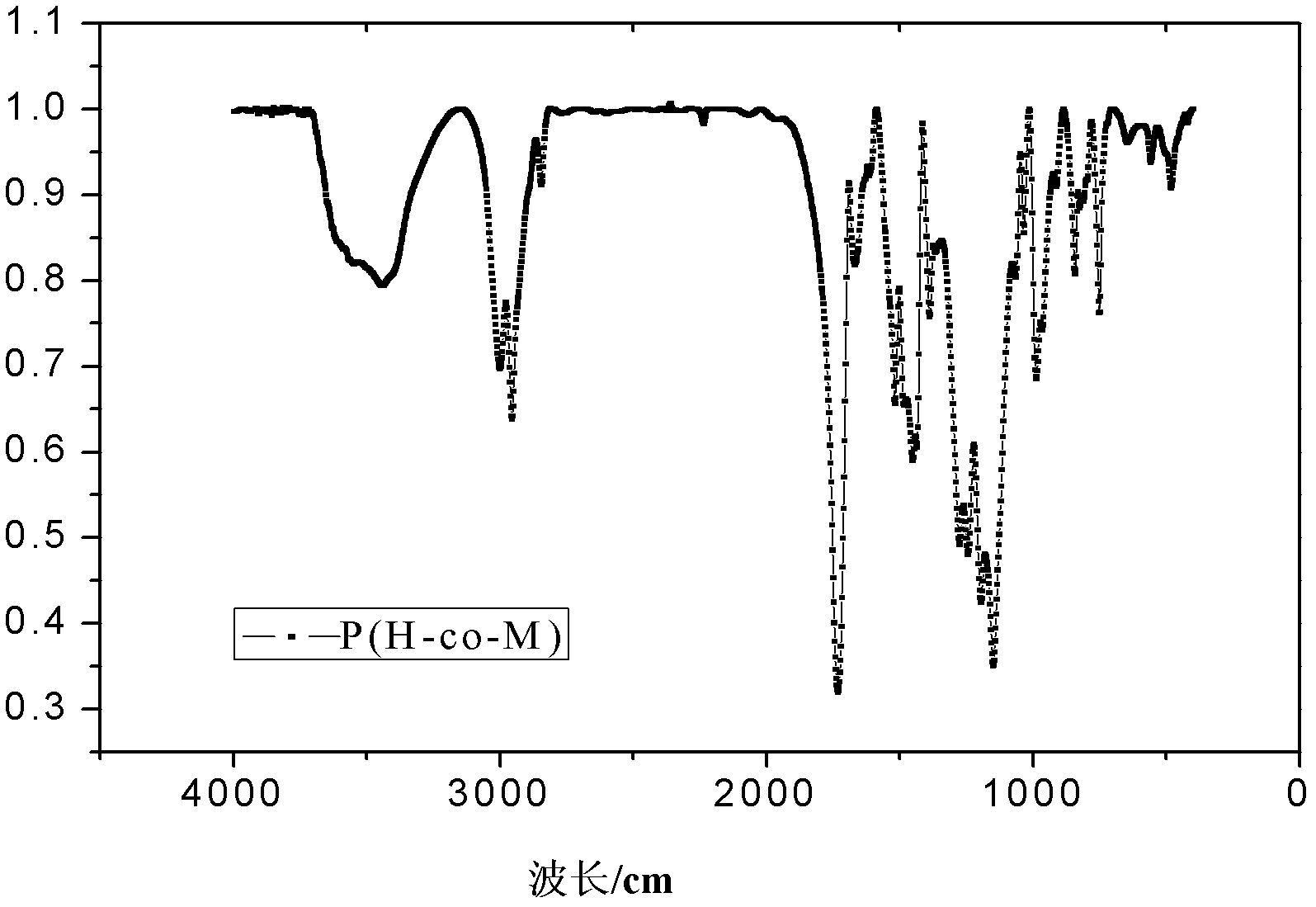

[0020] In a 10ml three-necked flask equipped with a stirring device, a thermometer, and a condenser, add 10ml N, N-dimethylformamide and 0.005mol of the compound N-(4-hydroxyl-3-methoxy-benzyl) containing capsaicin structure ) acrylamide, after mixing evenly, add 0.05mol methyl methacrylate, N 2 Stir at 80°C under protection to make it evenly mixed, then add 0.4g of initiator azobisisobutyronitrile, and react at a constant temperature of 80°C for 20 hours in an airtight chamber to obtain a polymer containing capsaicin structure. The molecular formula of the compound N-(4-hydroxyl-3-methoxy-benzyl)acrylamide containing capsaicin structure is shown in figure 1 ; The infrared spectrum of the polymer containing capsaicin structure is shown in figure 2 . Dissolve 0.2-0.6g of the above polymer, 0.5-1.5g of polyacrylic acid, 0.4g of water, 8g of polyethylene glycol, and 18g of polysulfone in 71.5-72.1g of N,N-dimethylacetamide, and stir at 60°C for 24h. Prepare the casting soluti...

Embodiment 2

[0023] According to the same steps as in Example 1, a polymer containing capsaicin structure was prepared. Dissolve 0.6-1.0g of the above polymer, 1.5-3.5g of polyacrylic acid, 0.4g of water, 8g of polyethylene glycol, and 18g of polysulfone in 69.1-71.5g of N,N-dimethylacetamide, and stir at 60°C for 24h. Prepare the casting solution, and then vacuum degassing for 24h. At room temperature, the casting solution was cast on a non-woven support layer fixed on a glass plate to form a film; dried in air for 5 seconds; soaked in a gel bath at 20°C for 24 hours; rinsed with deionized water to obtain an ultrafiltration membrane.

[0024] The performance of the ultrafiltration membrane was measured, and the results are as follows. Measure its performance. The contact angle of the membrane surface is 43.56-49.82°; the stable flux is 119.0-126.9L / m at the concentration of 5mg / L humic acid solution, operating pressure 0.1MPa, and temperature 20°C 2 h, the retention rate of stable orga...

Embodiment 3

[0026] Add 10ml N, N-dimethylformamide and 0.005mol compound N-(4-hydroxyl-3-methoxy-benzyl) containing capsaicin structure successively in a 10ml three-neck flask equipped with a stirring device, a thermometer, and a condenser Base) acrylamide, after mixing evenly, add 0.01mol methyl methacrylate and 0.01mol ethyl acrylate, N 2 Stir at 70°C under protection to mix evenly, then add 0.4g of initiator azobisisobutyronitrile, and react at a constant temperature of 90°C for 20 hours in a closed chamber to obtain a polymer containing capsaicin structure. Dissolve 1.0g of the above polymer, 2.5-4.0g of polyethylene oxide, 0.4g of water, 8g of polyethylene glycol, and 18g of polysulfone in 73.1g of N,N-dimethylacetamide, and stir at 60°C for 24 hours to prepare a casting Membrane liquid, and then vacuum defoaming for 24h. At room temperature, the casting solution was cast on a non-woven support layer fixed on a glass plate to form a film; dried in air for 5 seconds; soaked in a gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com