Preparation method of metal organic framework polyamide thin-layer nano composite membrane (UiO-66/TFN)

A metal-organic framework and nanocomposite technology, applied in the field of metal-organic frameworks, can solve the problems of unstable reverse osmosis membrane modified coating, complex and harsh modification conditions, and inability to maintain anti-adsorption performance all the time, so as to improve the anti-biological pollution. performance, the effect of improving antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

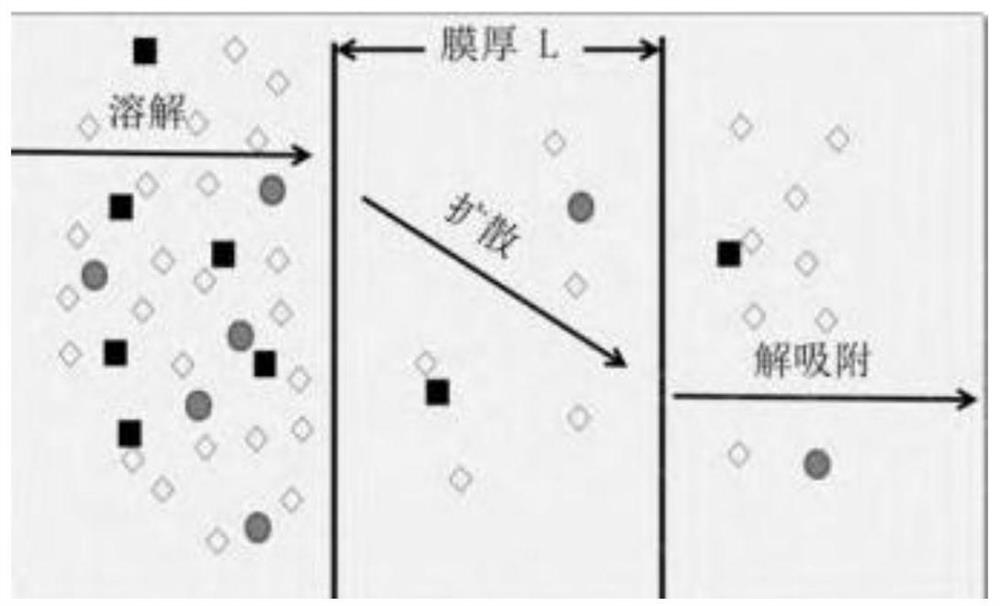

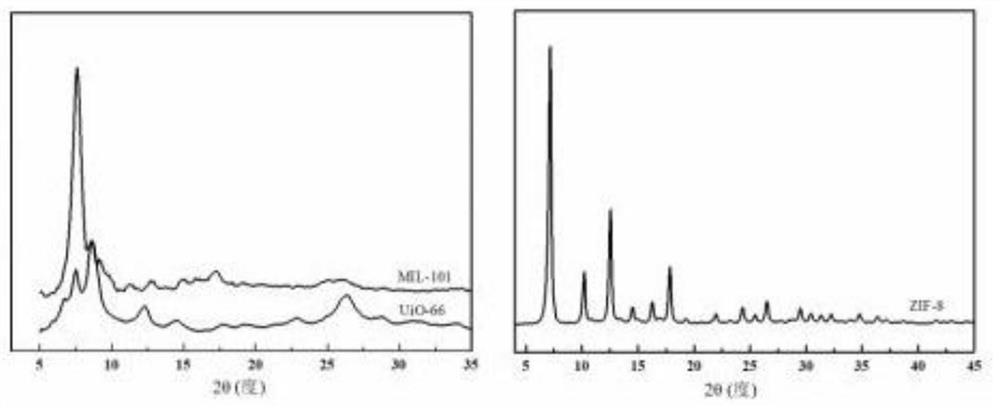

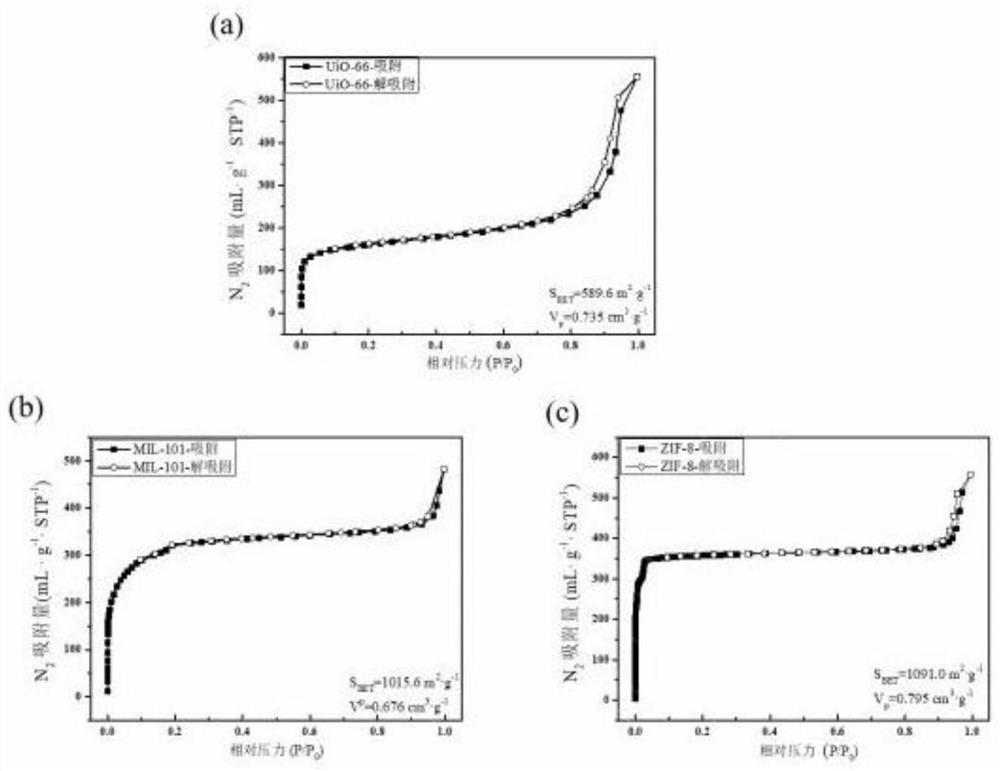

[0053] Figure 1-23 Show the preparation method of the metal-organic framework polyamide thin-layer nanocomposite film (UiO-66 / TFN) of an embodiment of the present invention, the preparation method is as follows:

[0054] Materials: polyamide thin-layer nanocomposite film (TNF); 2-methylimidazole, 2-sulfonic terephthalic acid monosodium salt, ZrCl2 and 1,2,4,5-benzenetetracarboxylic acid; Zn(NO3) 2.6H2O and CrO3; 1,4-dioxane, NaCl, KCl, MgCl2, LiCl analytically pure, concentrated HCl, methanol; ultrapure water, conductivity less than 1.0μs / cm, self-made in the laboratory, MIL-101 nanometer Particles, ZIF-8 nanoparticles.

[0055] Among them, the concentration of 2-methylimidazole is (77.2cm 3 / mol), the concentration of 2-sulfonic acid terephthalic acid monosodium salt is (50.2cm 3 / mol), ZrCl 2 The concentration of Zn(NO 3 ) 2 ·6H 2 The concentration of O is (121.1g / mol), CrO 3 The concentration of is (120.3g / mol); the concentration of 1,4-dioxane is (131.4g / mol), the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com