Ceramic column array reinforced metal based composite material or part and preparation method thereof

A technology of composite materials and ceramic columns, which is applied in heat exchange equipment, rotors, cylinders, etc., can solve the problems of complex process, reinforcement phase shedding, and difficulty in achieving a high volume fraction, and achieve simple preparation process, improved wear resistance, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

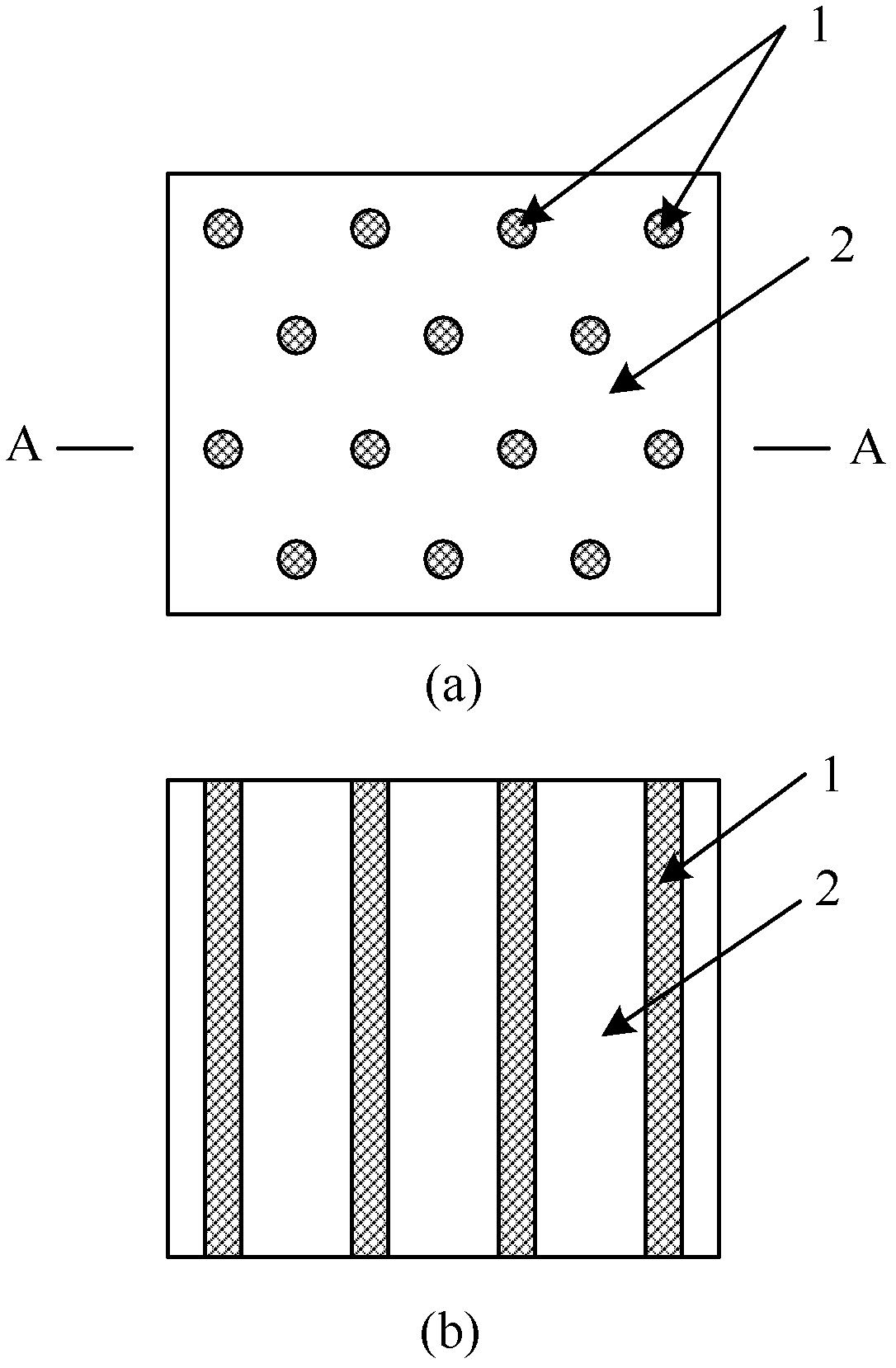

[0026] Al 2 o 3 Preparation method of ceramic pillar array integrally reinforced Al-based composite material

[0027] Step 1: Pretreatment of Ceramic Columns: First, the dimensions are Al 2 o 3 Clean the ceramic column, and then use Mo, MnO, Al with a mass ratio of 70:12:10.5:7.5 and a mass ratio of 70:12:10.5:7.5 for the mixed powder that has been ball-milled. 2 o 3 and SiO 2 Metallization mixed powder, ethylene oxalate and collodion solution in the ratio of 5g: 6ml: 5ml prepared Mo-Mn metallization paste coated on the cleaned Al 2 o 3 On the surface of the ceramic column, after drying, place it in a hydrogen furnace at 1450°C, keep it warm for 50 minutes for metallization, then perform electroplating or electroless plating of 5-10μm Ni, and finally heat it in a vacuum furnace at 1000°C for 60 minutes for sintering Ni treatment .

[0028] Step 2: Fixing of the ceramic array: metallized Al 2 o 3 The ceramic columns are arranged regularly according to the center spa...

Embodiment 2

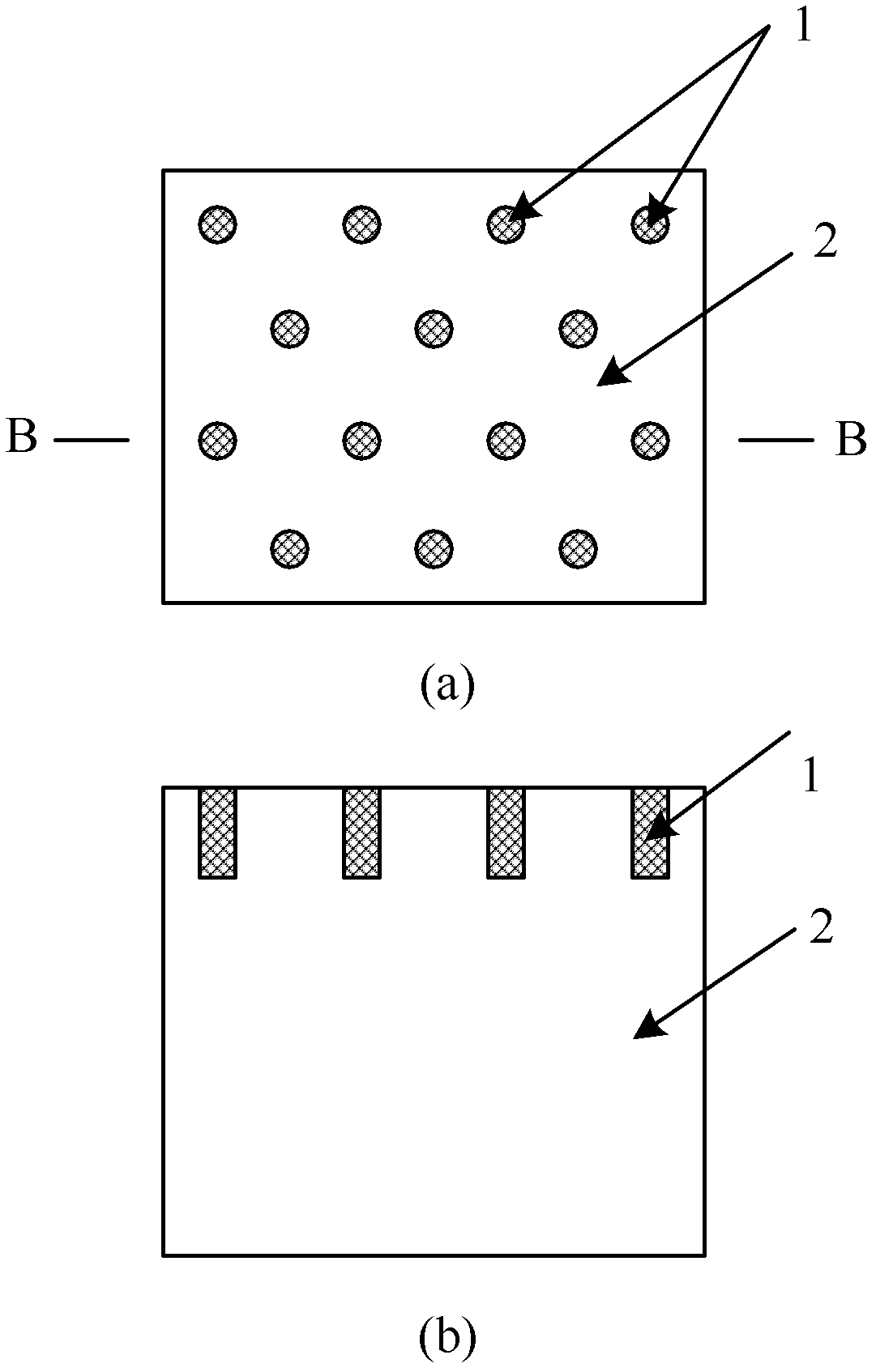

[0031] Al 2 o 3 Preparation method of ceramic pillar array integrally reinforced Al-based composite material

[0032] Step 1: Pretreatment of Ceramic Columns: First, the dimensions are Al 2 o 3 The ceramic column was cleaned, and then the ceramic column was buried in NiSO with a mass ratio of 1:1 4 ·6H 2 O and Na 2 SO 4 mixed salt, and then heated to 900 ° C for 60 minutes to make NiSO 4 Melt and decompose, then cool, and then boil to wash off the salt on the surface of the ceramic.

[0033] Step 2: Fixation of the array: the pretreated Al 2 o 3 The ceramic pillars are alternately arranged with a center distance of 10 mm, and are directly inserted and fixed at the bottom of the sand mold.

[0034] Step 3: Metal casting: At a pouring temperature of 780 ° C, the molten Al alloy (brand ZL104) is poured into a preheated metal mold with a ceramic column array by using a negative pressure casting method, and the ceramic array and Al Alloy composite as a whole.

Embodiment 3

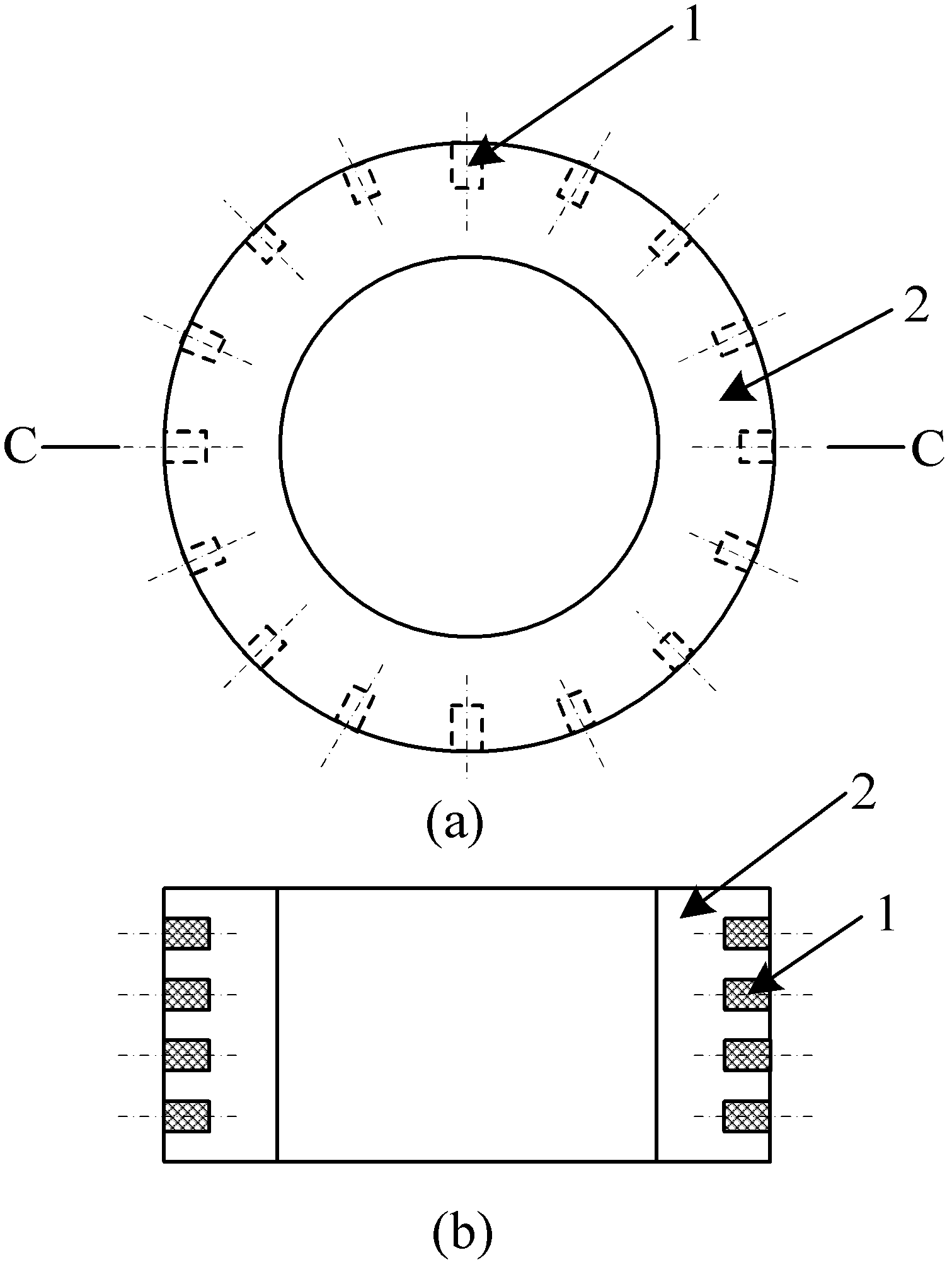

[0036] Al 2 o 3 , ZrO 2 and SiO 2 Preparation method of ceramic pillar array integrally reinforced Mg-based composite material

[0037] Step 1: Pretreatment of Ceramic Columns: First, the dimensions are Al 2 o 3 , ZrO and SiO 2 The ceramic column is cleaned, and then the ball-milled TiH with a median diameter of 2.785 microns is used 2 Powder, ethylene oxalate and collodion solution in the ratio of 5g: 4ml: 4ml prepared TiH 2 The ointment was applied to the surfaces of the three kinds of ceramic columns after cleaning, and after drying, they were placed in a vacuum furnace at 1000°C and kept warm for 30 minutes.

[0038] Step 2: Fixation of the array: the pretreated Al 2 o 3 , ZrO 2 and SiO 2 The ceramic pillars are alternately arranged with a center distance of 10 mm, and are directly inserted and fixed at the bottom of the sand mold.

[0039] (3) Metal casting: At a pouring temperature of about 700 ° C, the molten Mg alloy (brand AZ91D) is poured into a preheat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com