Method for preparing multi-metal nanoparticles by one-step coreduction

A multi-metal and nanoparticle technology, applied in nanotechnology and other directions, can solve problems such as inability to large-scale production, harsh and complex experimental conditions, application limitations, etc., to achieve good experimental repeatability, simple and fast experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

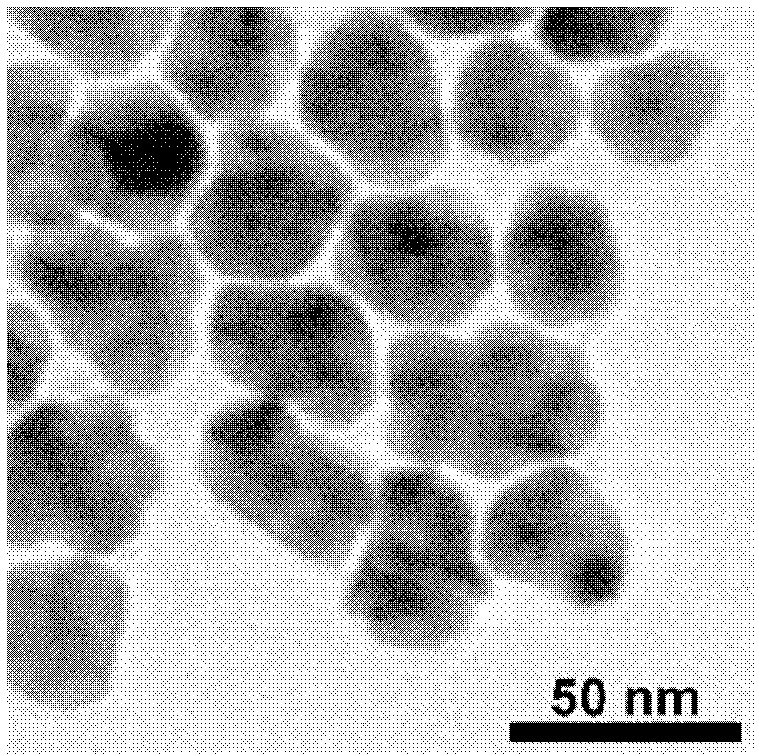

[0020] 0.0648mL concentration of 0.04g / mL of HAuCl 4 solution and 0.0625 mL of H at a concentration of 0.04 g / mL 2 PdCl 6 The solution was dissolved in 50mL deionized water, and the total concentration of metal ions was 2.5×10 -4 mol / L, HAuCl 4 with H 2 PdCl 6 The molar ratio between them is 1:1, the reaction system is stirred and heated to 100° C. to boil the solution to obtain a tan transparent solution. Then, 1 mL of 2 wt % sodium citrate solution was added to the reaction system. After keeping the solution boiling for 10 minutes, stop heating and continue stirring to cool to room temperature, such as figure 1 As shown, the spherical-like Au / Pd binary metal nanoparticles with an average particle diameter of 34.4nm were obtained.

Embodiment 2

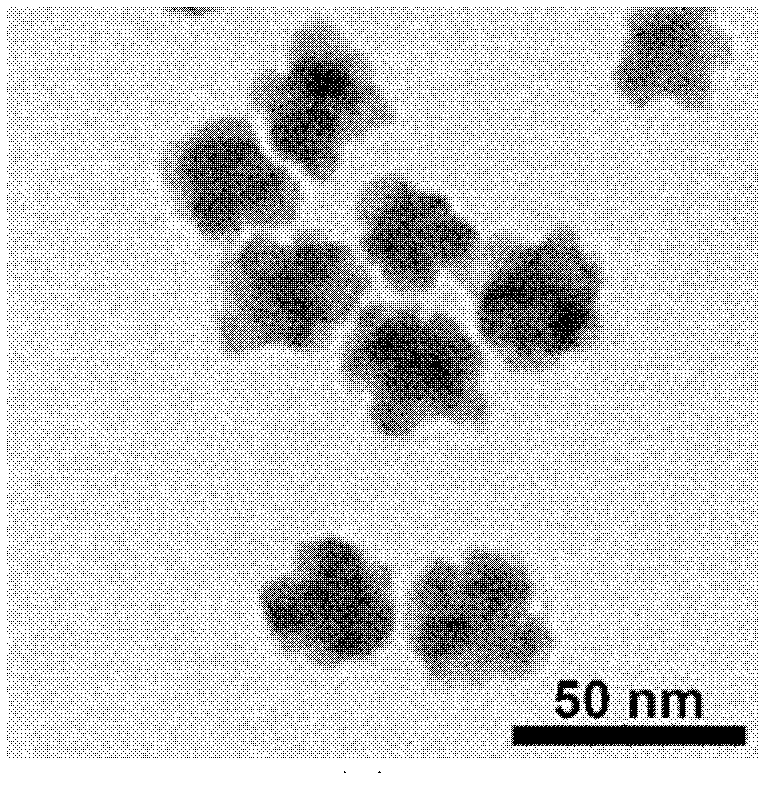

[0022] 0.0648mL concentration of 0.04g / mL of HAuCl 4 solution and 0.0625 mL of H at a concentration of 0.04 g / mL 2 PdCl 6 The solution was dissolved in 50mL deionized water, and the total concentration of metal ions was 2.5×10 -4 mol / L, HAuCl 4 with H 2 PdCl 6 The molar ratio between them is 1:1, the reaction system is stirred and heated to 100° C. to boil the solution to obtain a tan transparent solution. Then, 3 mL of sodium citrate solution with a concentration of 2 wt % was added to the reaction system. After keeping the solution boiling for 10 minutes, stop heating and continue stirring to cool to room temperature, such as figure 2 As shown, flower-shaped Au / Pd binary metal nanoparticles with an average particle diameter of 28.6 nm were obtained.

Embodiment 3

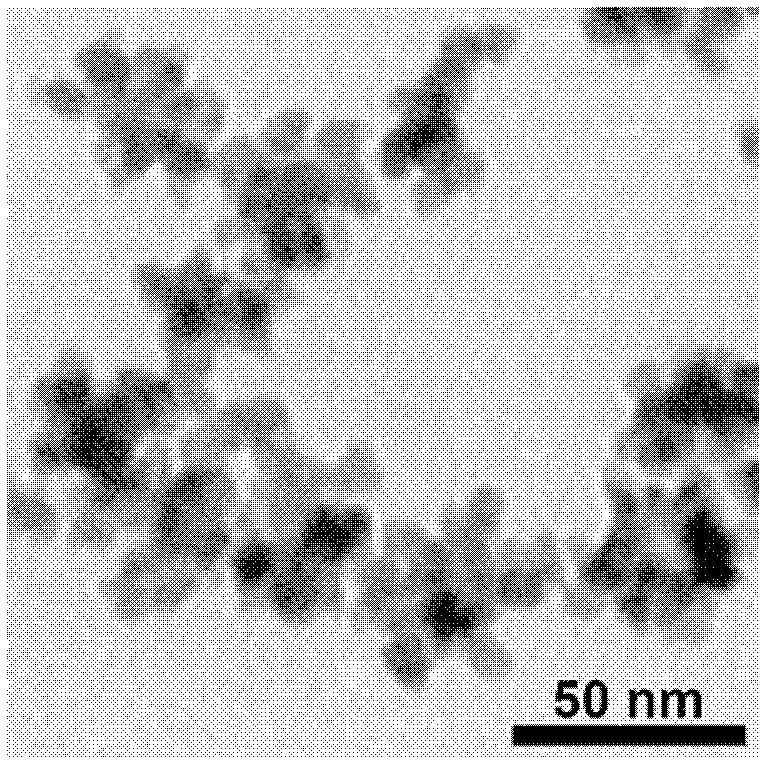

[0024] 0.0648mL concentration of 0.04g / mL of HAuCl 4 solution and 0.0625 mL of H at a concentration of 0.04 g / mL 2 PdCl 6 The solution was dissolved in 50mL deionized water, and the total concentration of metal ions was 2.5×10 -4 mol / L, HAuCl 4 with H 2 PdCl 6 The molar ratio between them is 1:1, the reaction system is stirred and heated to 100° C. to boil the solution to obtain a tan transparent solution. Then, 4 mL of 2 wt % sodium citrate solution was added to the reaction system. After keeping the solution boiling for 10 minutes, stop heating and stir to cool to room temperature, such as image 3 As shown, dendritic Au / Pd binary metal nanoparticles were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com