Coating sunshade composite material with high reflectivity and preparation method thereof

A technology of composite materials and high reflectivity, applied in the direction of reflection/signal coatings, coatings, chemical instruments and methods, etc., can solve problems such as sunshade, flame retardant and other comprehensive properties that cannot be satisfied, and achieve optimal surface area to volume ratio, surface area Small, low porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

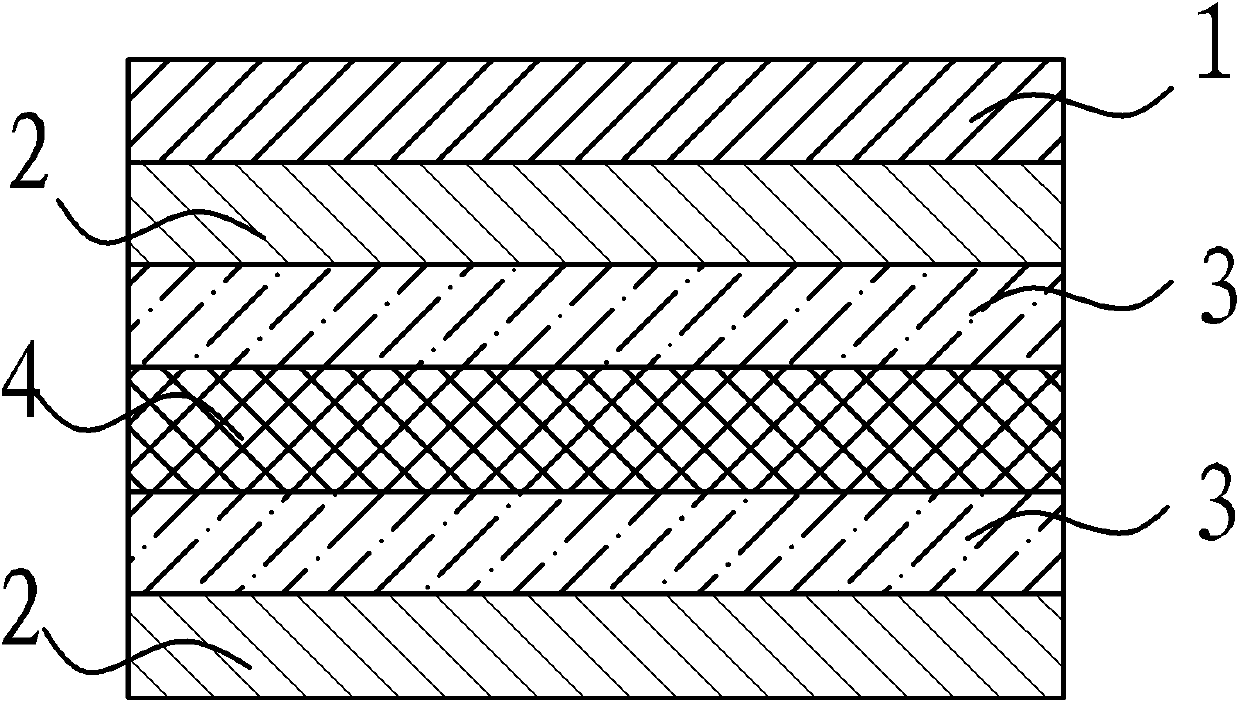

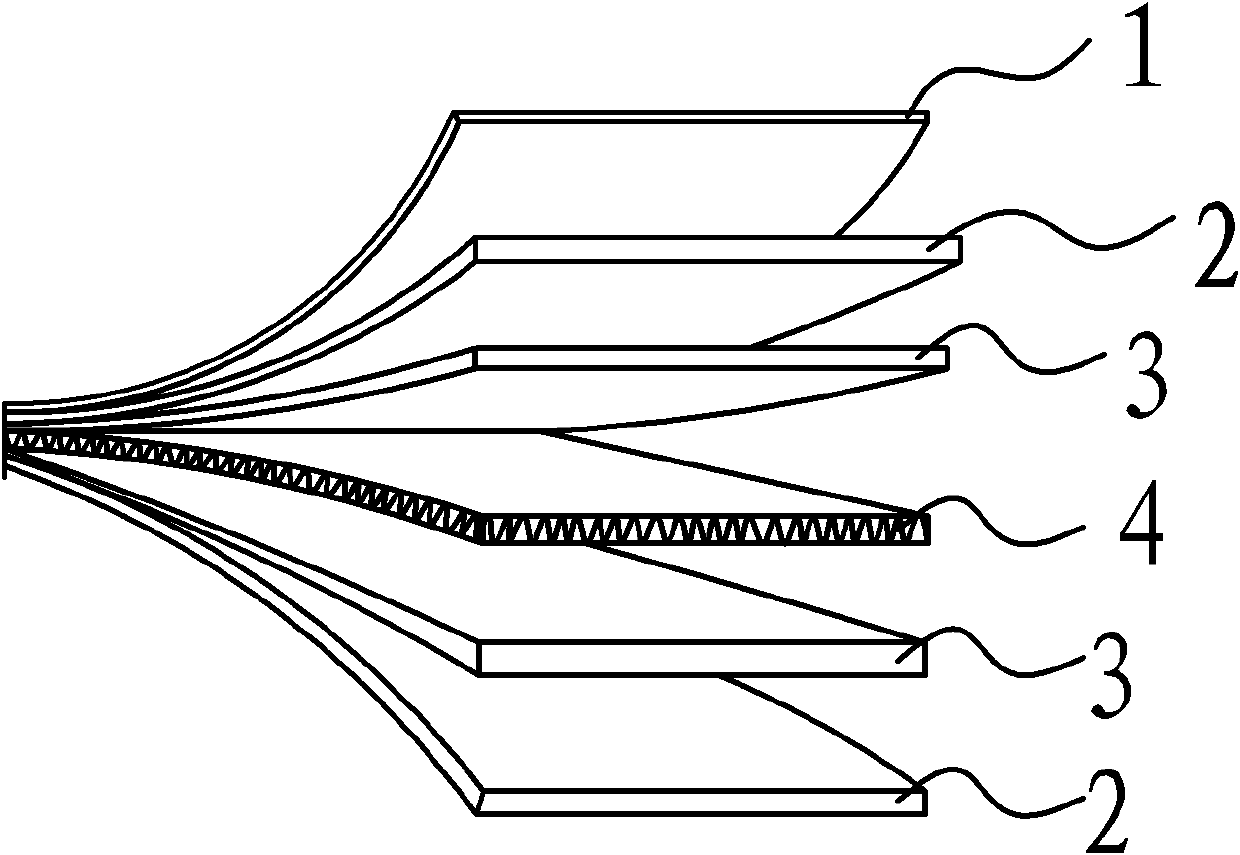

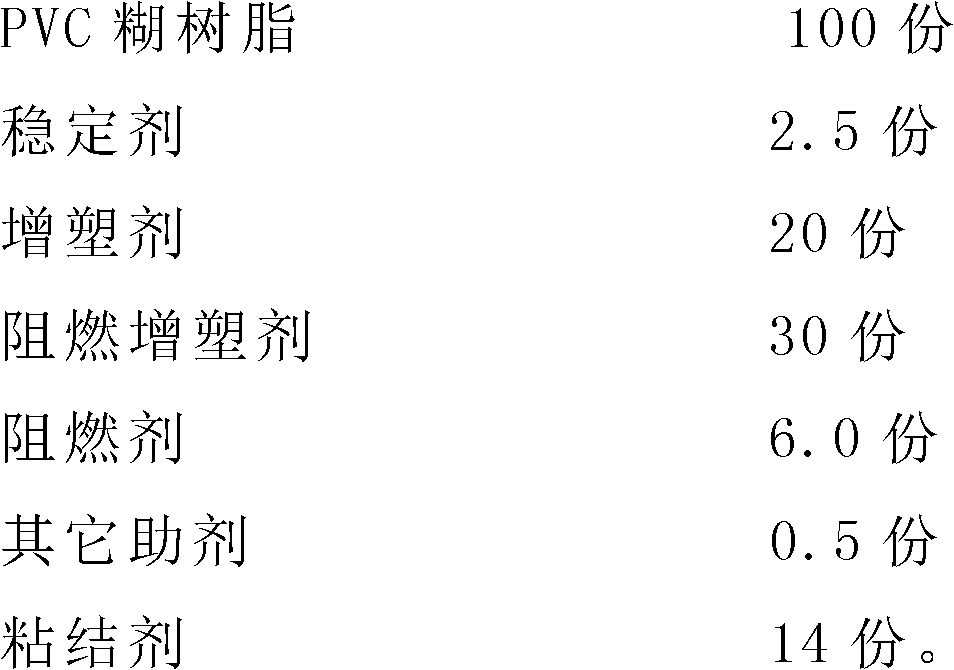

[0040] Select polyester fiber fabric, it is cut into polyester base material layer, select PVC primer composition according to following parts by weight:

[0041]

[0042] The flame retardant plasticizer is triphenyl phosphate, the flame retardant is antimony trioxide, other additives are rutile titanium dioxide, and the binder is polyisocyanurate Bonding Agent2005 .

[0043] Stirring and mixing: Mix and stir the liquid components according to the above formula, add PVC paste resin in batches and stir evenly, then add the rest of the powder components and stir evenly; first perform rapid grinding on the three-roller grinder, and then finely Grinding, add a certain amount of adhesive in proportion while stirring before primer, and then stir evenly.

[0044] The PVC primer sol is penetrated into the inside of the polyester substrate by means of dipping and rubber wheel rolling, and the polyester substrate layer and the PVC primer are bonded by the above-mentioned adhesive. ...

Embodiment 2

[0053] Prepare PVC coating according to the method for embodiment 1, difference is:

[0054] The components and parts by weight of the PVC base coat are:

[0055]

[0056]

[0057] The flame retardant plasticizer is tricresyl phosphate; the flame retardant is antimony pentoxide, and the other additives are 4 parts of antioxidant and 4 parts of rutile titanium dioxide; The agent is Polyisocyanurate Bonding Agent2001.

[0058] The components of the top coat and parts by weight thereof are:

[0059]

[0060] The flame retardant plasticizer is tricresyl phosphate; the flame retardant is antimony trioxide, and the other additives are 6 parts of ultraviolet absorbers and 4 parts of rutile titanium dioxide.

[0061] The control parameters in the PVC coating preparation method are shown in Table 1.

[0062] Table 1

[0063]

[0064] Prepare the aluminum-containing reflective layer according to the method of Example 1 to obtain composite material A2, the difference is t...

Embodiment 3

[0069] Prepare PVC coating according to the method for embodiment 1, difference is:

[0070] The components and parts by weight of the PVC base coat are:

[0071]

[0072] The flame retardant plasticizer is toluene diphenyl phosphate; the flame retardant is antimony trioxide; the binder is polyisocyanurate Bonding Agent TP LXS51066; other additives are rutile type of titanium dioxide.

[0073] The components of the top coat and parts by weight thereof are:

[0074]

[0075] The flame retardant plasticizer is toluene diphenyl phosphate; the flame retardant is antimony trioxide, and other additives are rutile titanium dioxide.

[0076] The control parameters in the PVC coating preparation method are shown in Table 3.

[0077] table 3

[0078]

[0079] Prepare the reflective layer containing aluminum according to the method of Example 1 to obtain composite material A3, the difference is that: the porosity of the composite material is 3%, and the reflective layer cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com