Preparation method for CNT (carbon nano tube)-SAPO (silicoaluminophosphate)-5 molecular-sieve composite membrane

A -SAPO-5, carbon nanotube technology, applied in the field of preparation of new carbon nanotube-SAPO-5 molecular sieve composite membrane, can solve the problems of natural gas and biogas calorific value reduction, unfavorable transportation and storage, etc., to promote directional growth , the effect of improving completeness and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

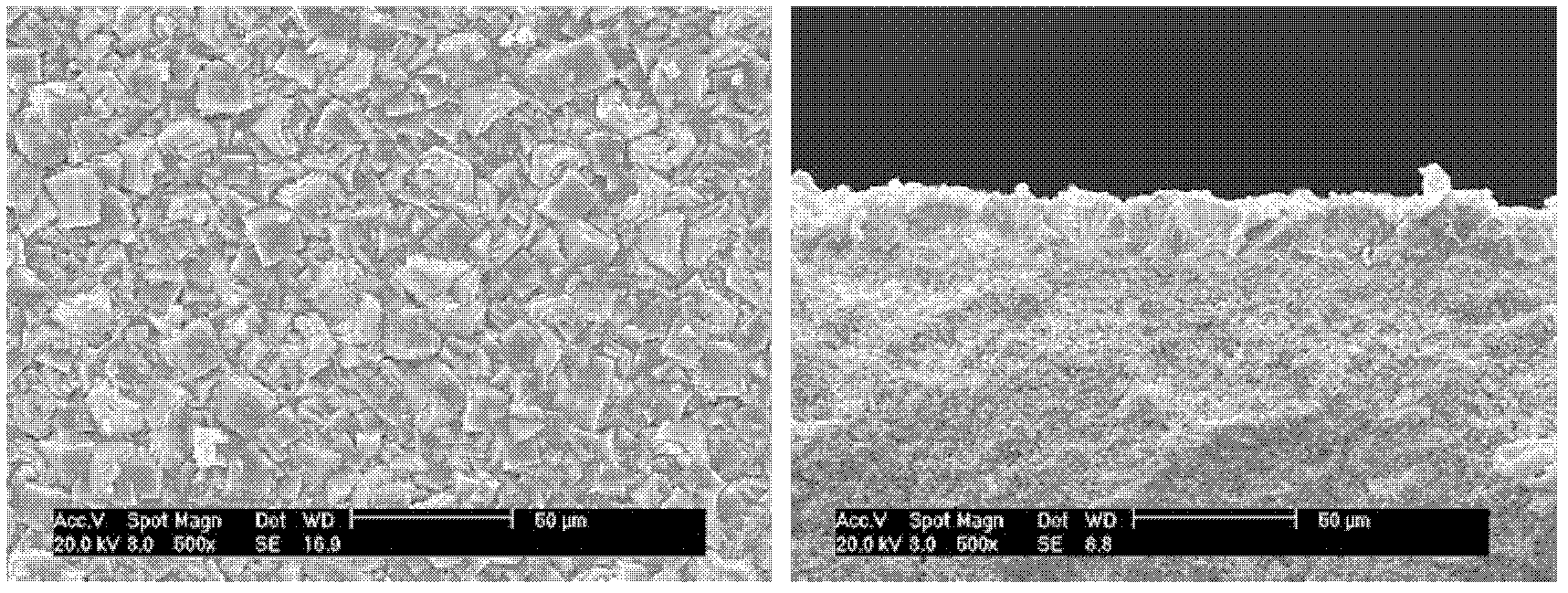

[0028] (1) Preparation of non-oriented FeSAPO-5 molecular sieve membrane on flake alumina support

[0029] According to 1Al 2 o 3 : 1.3P 2 o 5 : 0.5SiO2 2 :3TPABr:1000H 2 O:0.3FeCl 3 (mol) ratio of materials to prepare synthetic liquid. The aluminum source in the reaction is aluminum isopropoxide. In order to fully dissolve it, aluminum isopropoxide is added to an aqueous phosphoric acid solution (50%-85% by mass), and stirred and dissolved at 60°C for about 5 hours. , the dissolved aluminum isopropoxide aqueous solution is basically a transparent liquid. Then FeCl 3 It was added to an aqueous phosphoric acid solution in which aluminum isopropoxide was dissolved, and stirred at room temperature for 2 hours. Then TPABr and tetraethyl orthosilicate were gradually added dropwise to the mixed solution, and stirred for two hours. After all substances were completely dissolved, the pH of the reaction solution was adjusted to about 6. The reaction solution was aged at room ...

Embodiment 2

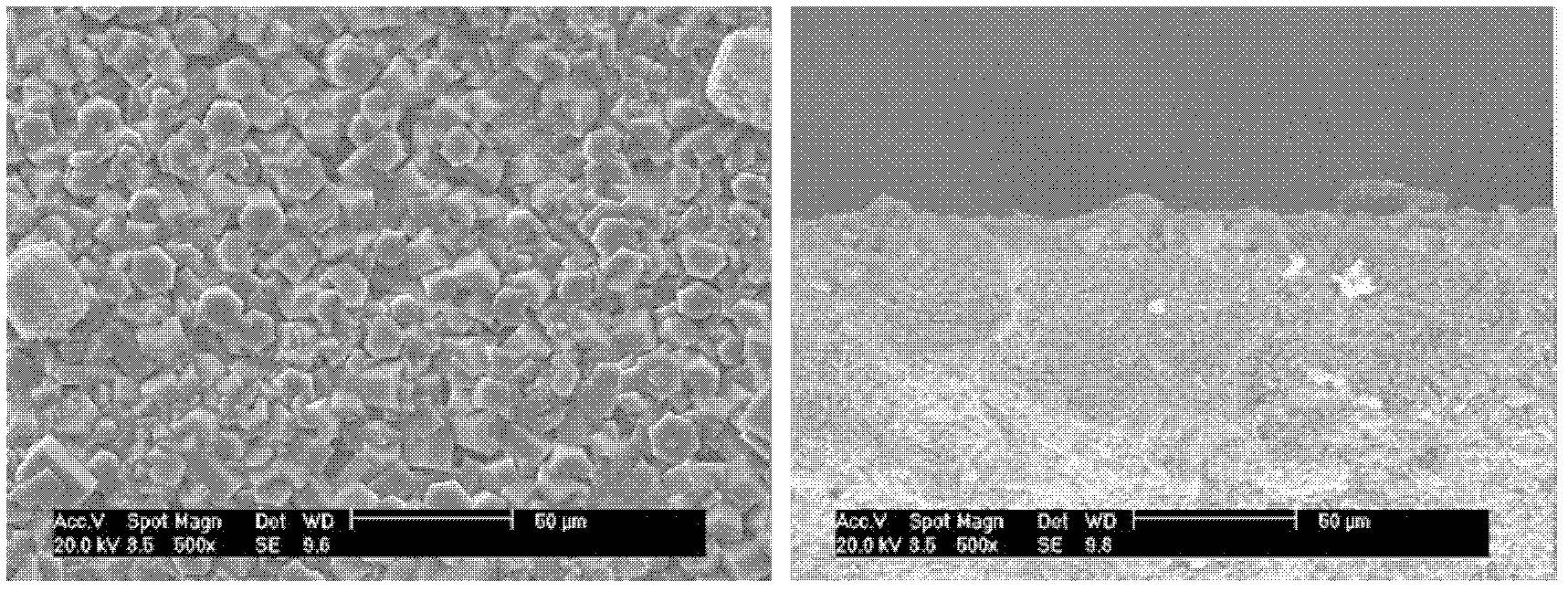

[0039] (1) Preparation of NiSAPO-5 molecular sieve membrane on a sheet-like alumina carrier

[0040] According to 1Al 2 o 3 : 0.8P 2 o 5 : 0.05SiO2 2 : 0.5TPAOH : 45H 2 O: 0.075Ni(NO 3 ) 2 (mol) ratio of materials to prepare synthetic liquid. The aluminum source in the reaction is sodium aluminate, and the fully dissolved sodium aluminate aqueous solution is basically a transparent liquid. Then, phosphoric acid dissolved with a certain amount of nickel nitrate was added dropwise to the sodium aluminate aqueous solution, and stirred at room temperature for 24 hours. Then TPAOH and silica sol were gradually added dropwise to the mixed liquid in sequence, and the stirring was continued for 2 hours. After all the substances were completely dissolved, the pH of the reaction liquid was adjusted to about 2. The reaction solution was aged at room temperature for 20 hours before being added to the reactor. Then 30ml of synthetic solution and α-Al 2 o 3 The carrier is placed...

Embodiment 3

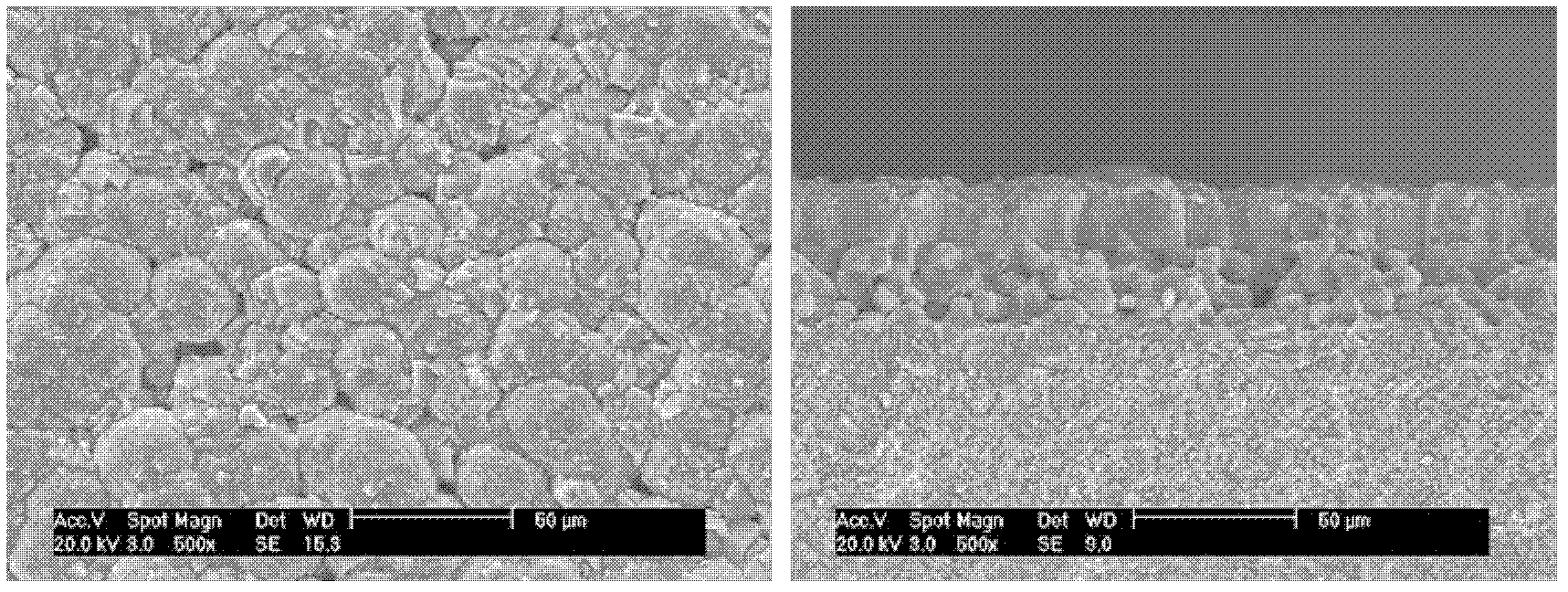

[0047] (1) Preparation of NiSAPO-5 molecular sieve membrane on tubular alumina carrier

[0048] Using the prior art-low-speed pulling method, first use 0.1-1.5wt% PVA aqueous solution to make the prepared NiSAPO-5 molecular sieve small particles (synthesized by microwave method) into 0.5-1wt% seed liquid; then The tubular alumina carrier is immersed in the seed liquid, and the carrier is pulled at a constant speed of 0.1-1cm / min; after standing for 1 hour at room temperature and in a low-dust environment, it is dried in an oven at 80°C for 24 hours. Repeat this operation 1-2 times, and a denser NiSAPO-5 molecular sieve seed layer can be prepared. Then, according to the steps described in Example 2, a complete tubular NiSAPO-5 molecular sieve membrane was prepared, the Ph value of the synthesis solution was adjusted to 4.5, and the mixed solution of tetraethylorthosilicate and silica sol was used as the silicon source of the synthesis solution.

[0049] (2) Detection of the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com