Aluminium adjuvant as well as preparation method and application thereof

An aluminum adjuvant and aluminum phosphate adjuvant technology, applied in chemical instruments and methods, pharmaceutical formulations, alumina/aluminum hydroxide, etc., can solve problems such as inhomogeneous product structure and unstable adjuvant performance, and achieve antibody titer high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

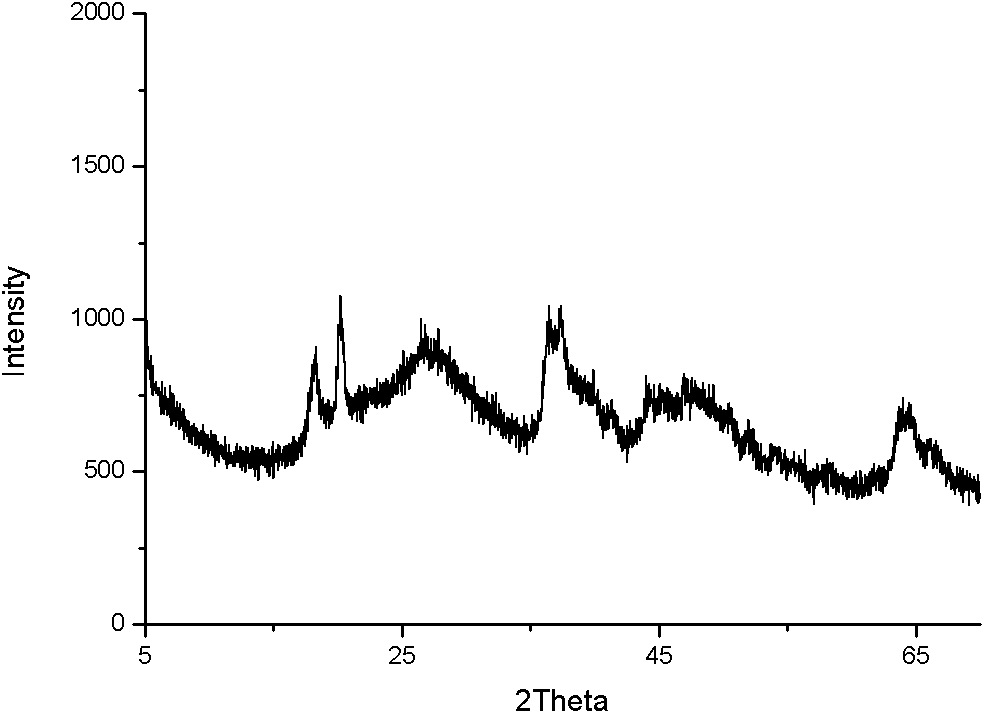

[0021] The invention provides a method for preparing an aluminum adjuvant, the method comprising contacting an aqueous solution of aluminum salt and / or phosphate with sodium hydroxide and / or ammonia solution, characterized in that the aluminum salt and / or phosphate The pH value of the whole process of contacting the aqueous solution with sodium hydroxide and / or ammonia solution is constant.

[0022] In the present invention, the constant pH value is a relative concept, that is, the above pH value can vary within a small range during actual operation, for example within ±0.1 range.

[0023] In the present invention, the mode of contacting the aqueous solution of the aluminum salt and / or phosphate with sodium hydroxide and / or ammonia solution is not particularly limited, as long as the aqueous solution of the aluminum salt and / or phosphate is mixed with hydrogen The pH value of the whole process of sodium oxide and / or ammonia solution contacting can be constant. For example, th...

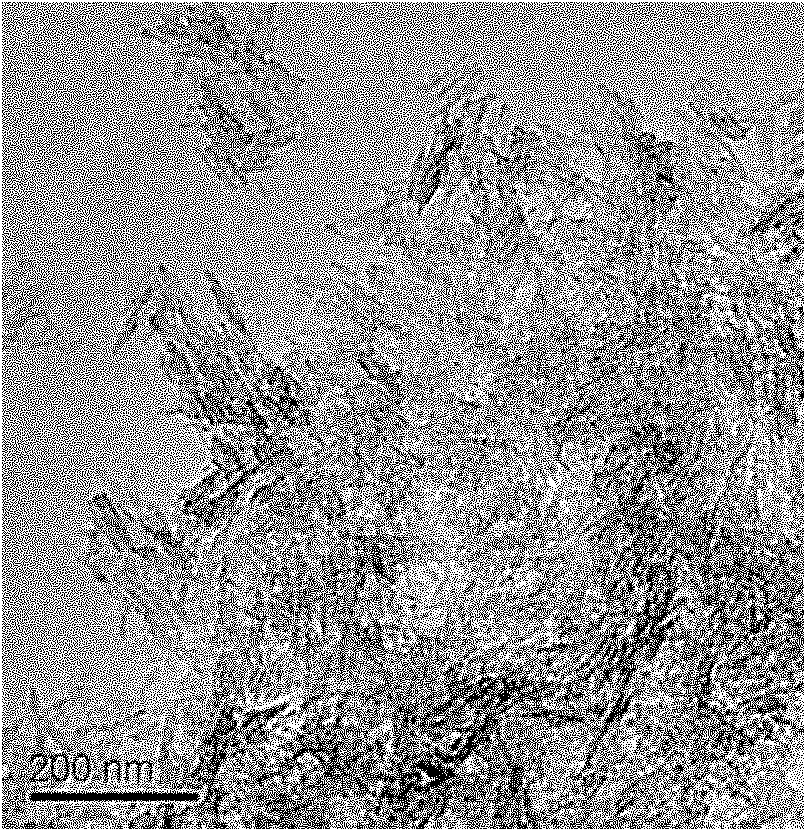

Embodiment 1

[0046] Weigh a certain amount of AlCl 3 ·6H 2 O, dissolved in distilled water, and prepared into an aqueous solution with an aluminum ion concentration of 0.05 mol / L; weigh a certain amount of NaOH, dissolve it in distilled water, and obtain a 0.5 mol / L NaOH aqueous solution. Using a peristaltic pump, the AlCl 3 ·6H 2 O solution and NaOH solution were pumped into the bottom of the 2L reactor, stirred, AlCl 3 ·6H 2 The flow rate of O is 50ml / min, the flow rate of NaOH solution is 15ml / min, the pH value of the reaction solution in the reactor is controlled at 10±0.1, and the reaction temperature is 25°C. When the aqueous solution passed into the reactor is full of overflow, the suspension is discharged from the overflow port into the receiving tank. After discarding the initial 2L of suspension, collect the suspension, and after standing for 5 hours, discard the supernatant solution, centrifuged to obtain a precipitate, and washed 3 times with distilled water. The precipit...

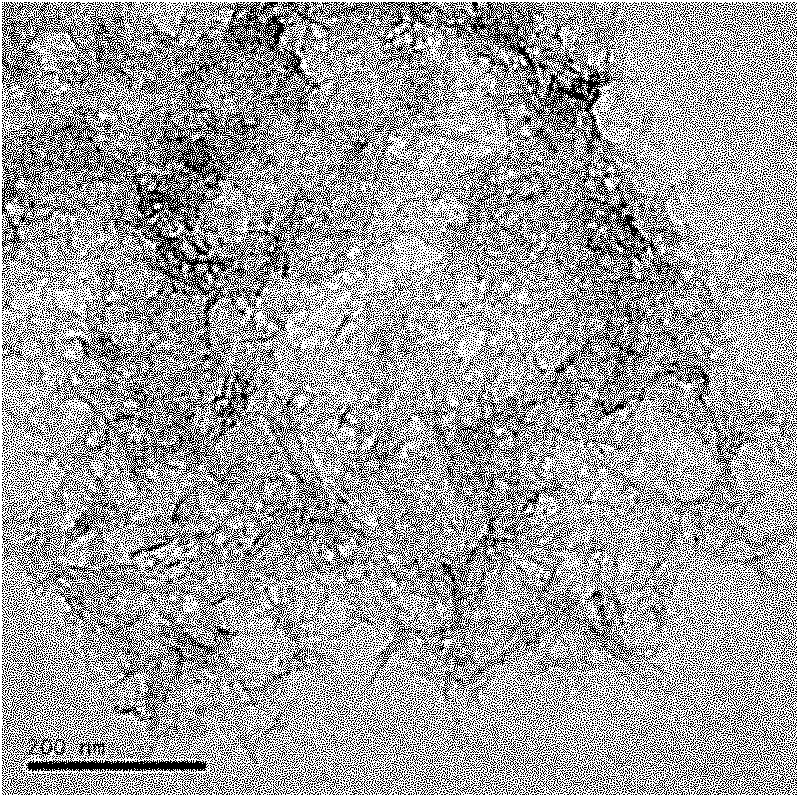

Embodiment 2

[0048] Weigh a certain amount of aluminum sulfate, dissolve it in distilled water, and prepare an aqueous solution with an aluminum ion concentration of 0.025mol / L; weigh a certain amount of NaOH, dissolve it in distilled water, and obtain a 0.21mol / L NaOH aqueous solution. Using a peristaltic pump, the AlCl 3 ·6H 2 O solution and NaOH solution were pumped into the bottom of the 2L reactor, stirred, AlCl 3 ·6H 2 The flow rate of O is 100ml / min, the flow rate of NaOH solution is 30ml / min, the pH value of the reaction solution in the reactor is controlled at 9.5±0.1, and the reaction temperature is 25°C. When the aqueous solution passed through filled the reactor, it began to overflow, and the suspension was discharged from the overflow port into the receiving tank. After discarding the initial 1L suspension, the suspension was collected, and after standing for 5 hours, the supernatant was discarded. , and centrifuged to obtain a precipitate, which was washed 3 times with dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com