Preparation method for mesoporous electrode and application thereof

An electrode and mesoporous technology, applied in the field of preparation of water treatment electrode materials, can solve the problems of weak material strength, high preparation cost, and limitations, and achieve the effect of improving conductivity, improving conductivity, and realizing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

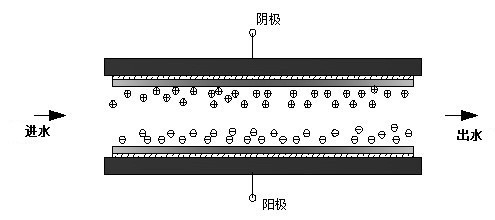

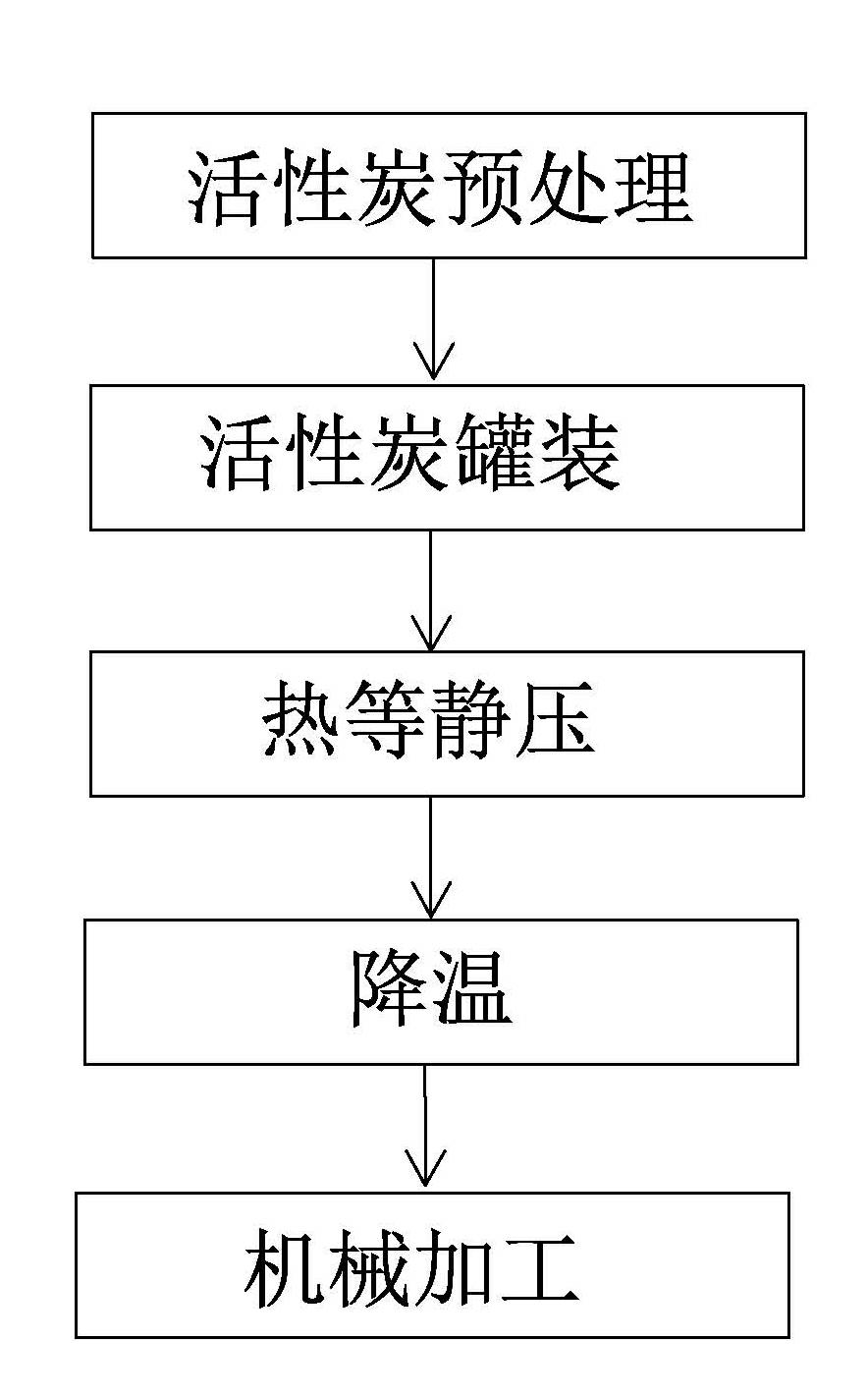

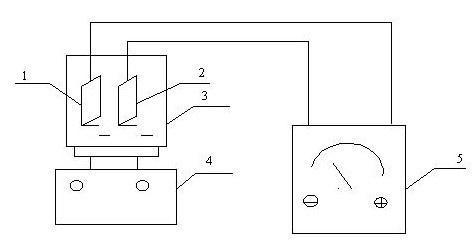

[0032] Such as figure 2 Shown in the flow chart of the preparation of the mesoporous electrode of the present invention, the specific surface area is 1500m 2 / g, activated carbon particles with an average pore size of 2nm were added with 500-mesh graphite powder during the grinding process (the mass ratio of activated carbon:graphite powder was 2:1), ground into 70-1000 mesh, passed through a 1000-mesh sieve, and washed with water at 100 Dry at -150°C for 3h. Put the pretreated activated carbon into a container, vacuumize and degas at 100-300°C for 1-2h, and then seal it, then carry out hot isostatic pressing at a temperature of 900°C and a pressure of 4000psi for 0.5- After 2 hours, cool down at a rate of 100-500°C / h, and then machine it into an electrode sheet of the desired shape. Use this example to prepare an electrode sheet image 3 Schematic diagram of the device for electro-adsorption desalination experiments.

example 2

[0034] The difference between Example 2 and Example 1 is that Example 2 adds carbon fiber (activated carbon: carbon fiber mass ratio is 2:1) in the activated carbon grinding process, and then prepares the electrode by the method of Example 1, and uses this example to prepare the electrode according to image 3 Schematic diagram of the device for electro-adsorption desalination experiments.

Embodiment 3

[0036] The difference between Example 3 and Example 1 is that in Example 3, no graphite powder or carbon fiber is added during the grinding process of activated carbon, and then the electrode is prepared by the method of Example 1. Use this example to prepare electrodes by image 3 Schematic diagram of the device for electro-adsorption desalination experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com