Municipal sludge pretreatment method enhancing sludge anaerobic fermentation acid production

A technology for sludge anaerobic fermentation and municipal sludge, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. It can solve the problem of limited effect, unsatisfactory effect, and affecting the effect of enzyme treatment and other problems, to achieve the effect of mild reaction conditions and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

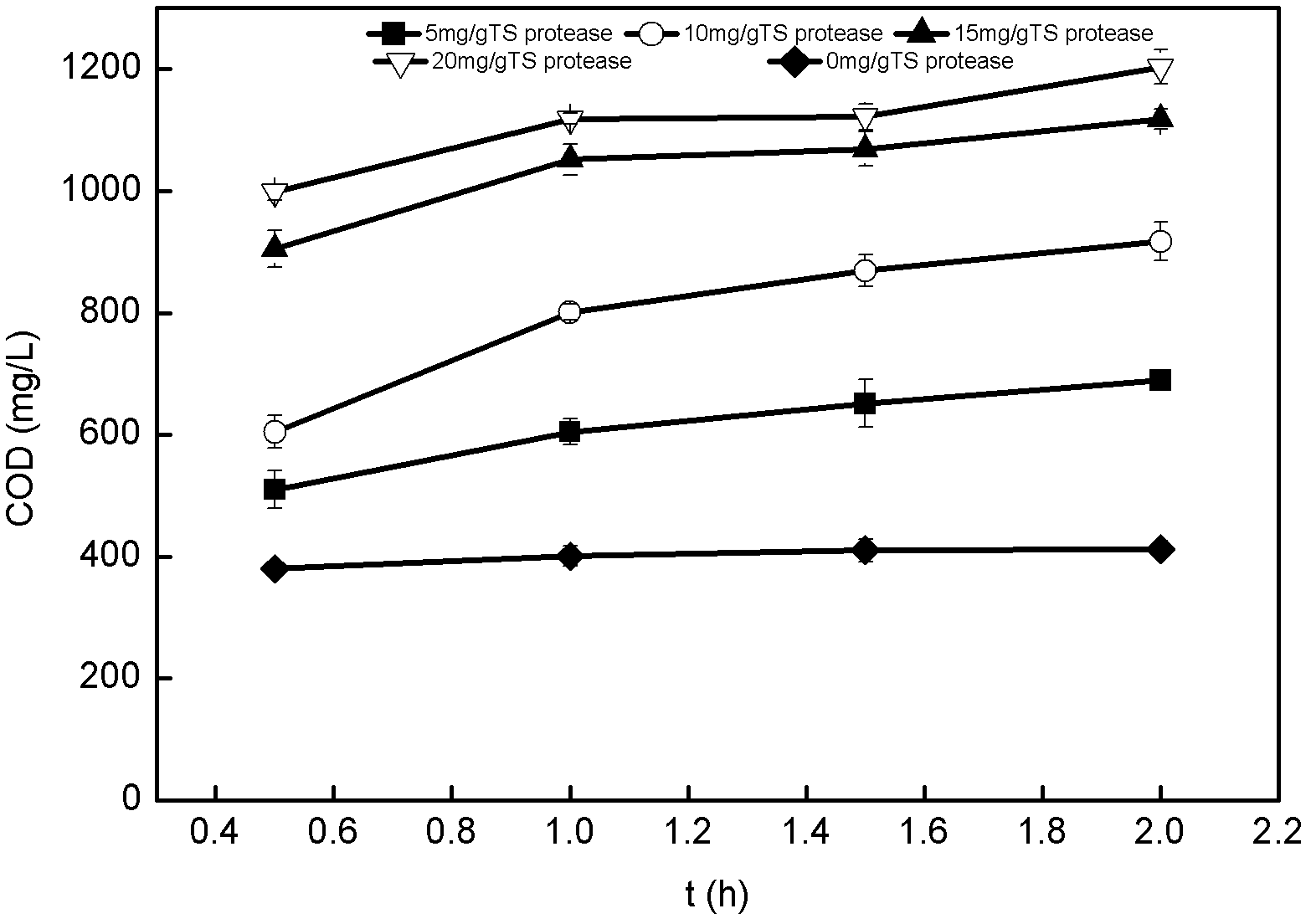

[0019] Embodiment 1, the influence of protease concentration and enzymolysis time on sludge pretreatment effect

[0020] The sludge was taken from the dewatered sludge of the secondary settling tank of Wuxi Lucun Sewage Treatment Plant. and 20mg / gTS, reacted for 2.0h under the stirring condition with a rotation speed of 120r / min, and took samples at the reaction time points of 0.5, 1.0, 1.5 and 2.0h respectively, and measured the SCOD of the water samples. The results showed that when the concentration of neutral protease was 20mg / gTS and the stirring time was 1.0h, the SCOD in the sludge supernatant could reach 1118.8mg / L, which was 1.8 times higher than that of the pretreated sludge solution.

Embodiment 2

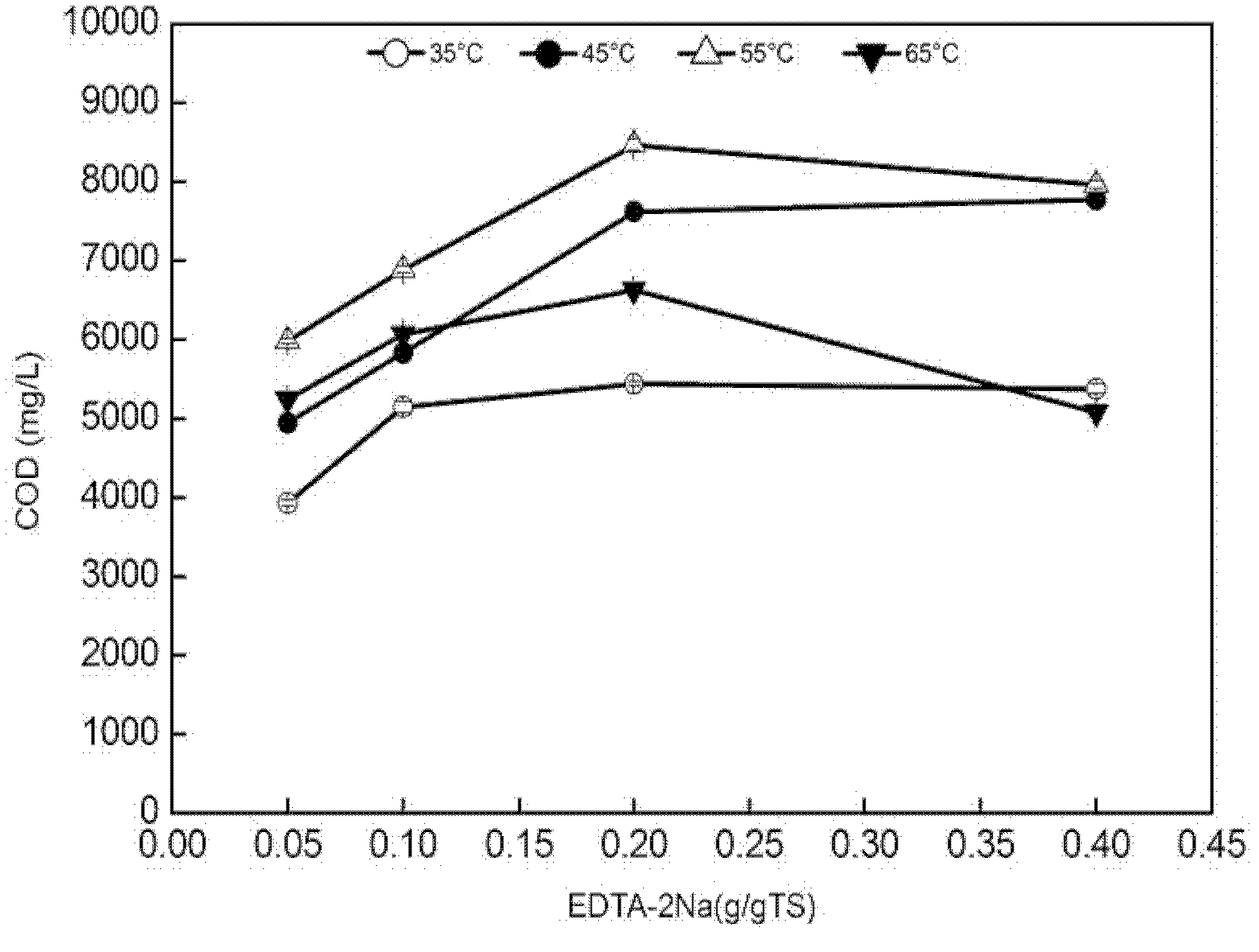

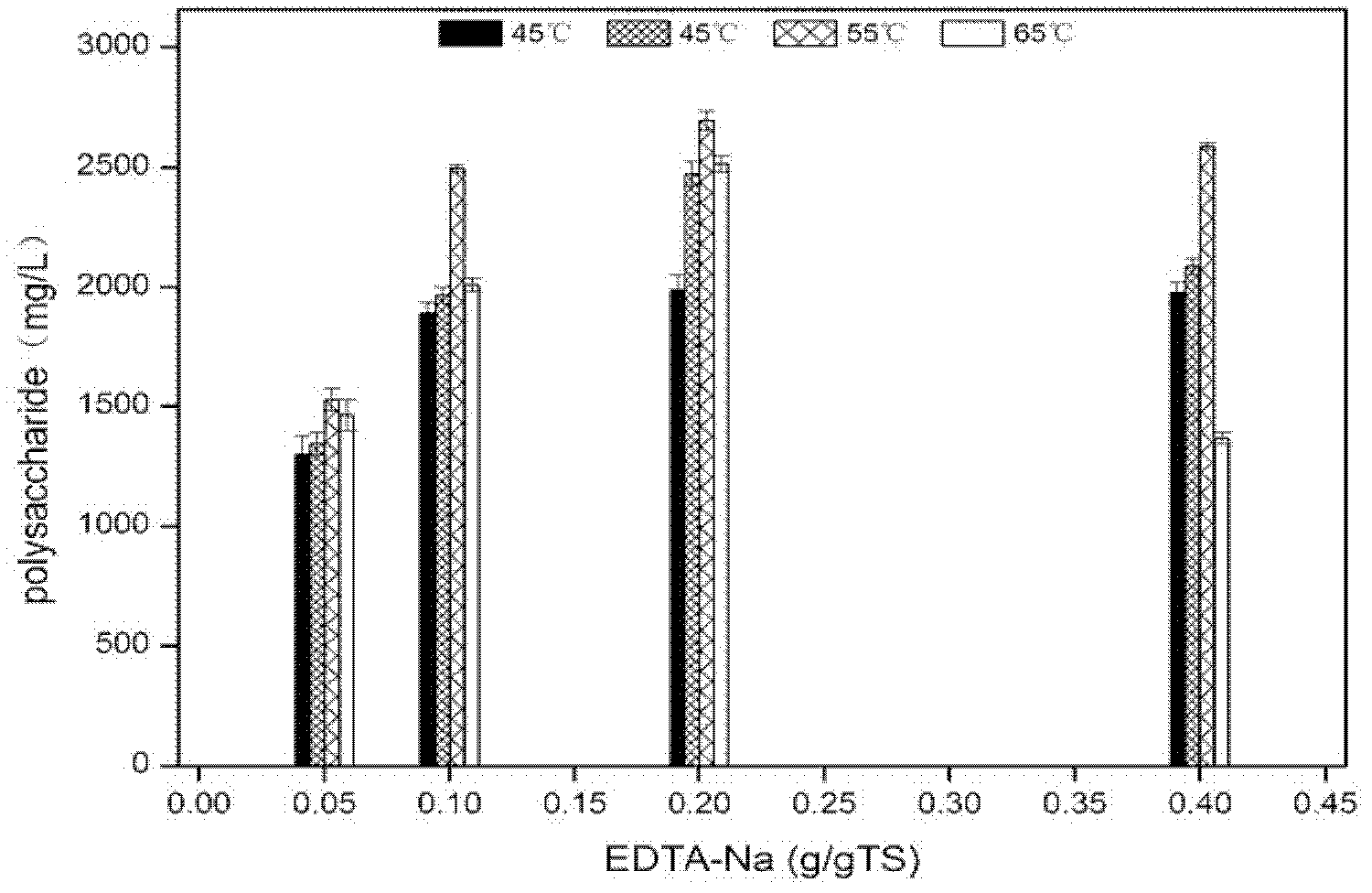

[0021] The influence of embodiment 2, temperature and EDTA-2Na salt concentration on sludge pretreatment

[0022] The source of sludge and other experimental conditions were the same as Example 1, and the enzyme concentration and stirring time were fixed at 20mg / gTS and 1.0h respectively, and the concentration of EDTA-2Na was set at five levels: 0, 0.05, 0.1, 02 and 0.4g / gTS, Each level was stirred for 1.0 h at temperatures of 35, 45, 55 and 65°C, respectively. The results show that when the concentration of EDTA-2Na is 0.2g / gTS and the temperature is 55℃, the concentration of SCOD in the sludge can reach 8470.0mg / L, the concentration of polysaccharide can reach 2695.1mg / L, and the concentration of protein can reach 156.7mg / L The pretreatment sludge solution increased by 20.0, 12.5 and 2.1 times respectively.

Embodiment 3

[0023] Embodiment 3, the influence of pH on sludge pretreatment effect

[0024] The source of sludge and other experimental conditions are the same as Example 1. The set temperature is 55°C, the concentration of EDTA-2Na salt is 0.2g / gTS, the concentration of enzyme is 20mg / gTS, and the stirring time is 1h. At different initial pH (4.0, 5.0 , 6.0, 7.0, 8.0) to pretreat sludge. The results showed that when the initial pH was 7.0, the concentration of SCOD in the sludge reached 8621.32mg / L, which was 20.4 times higher than that of the untreated sludge solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com