Plastic septic tank

A technology of plastics and plastic boards, applied in the direction of biological sludge treatment, etc., can solve the problems of construction cost and long construction period, unfavorable protection of groundwater resources, non-compliance with environmental protection policies, etc., and achieve shortened construction period, high cost performance and convenient management Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

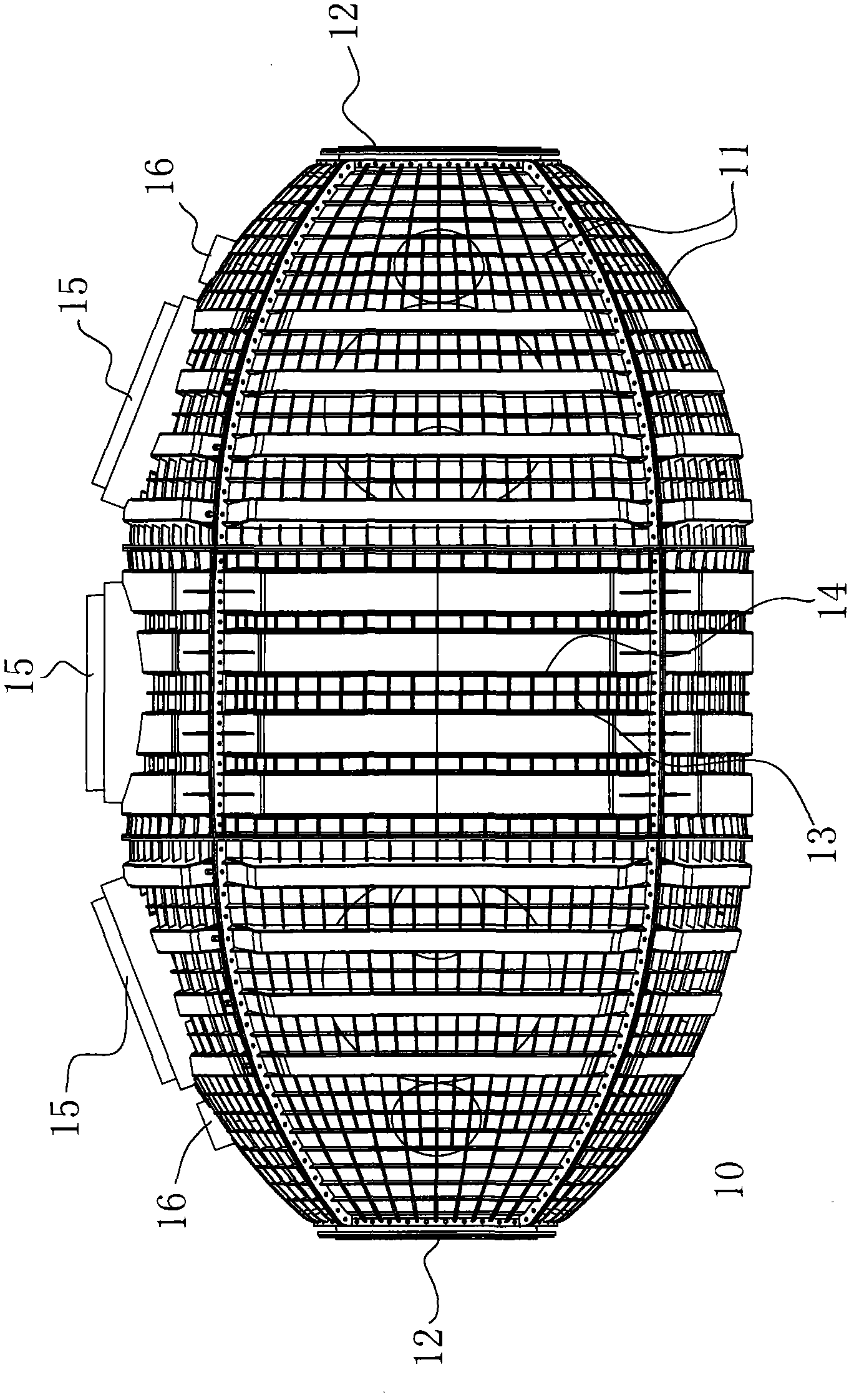

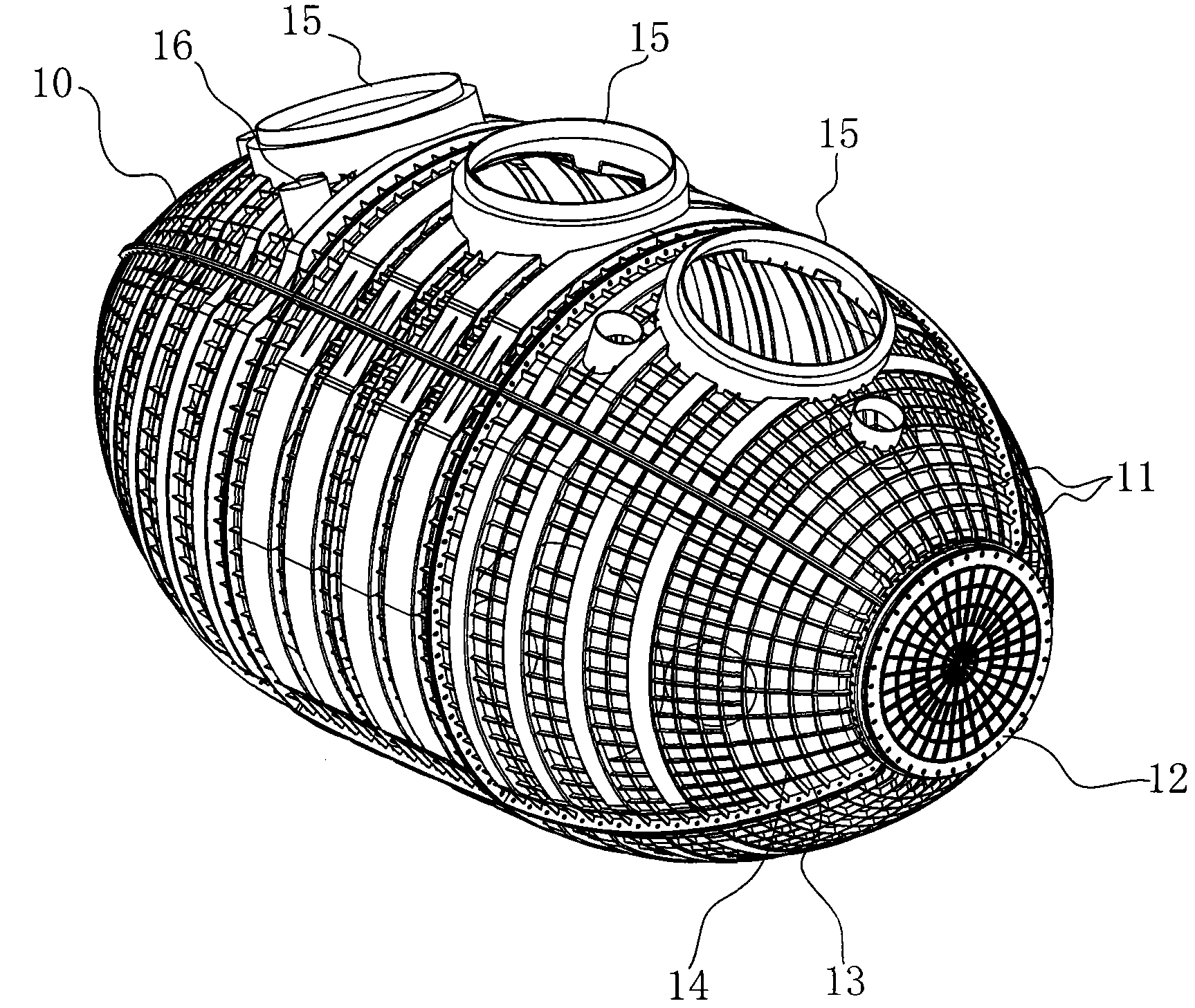

[0012] A preferred plastic septic tank, the septic tank is composed of the inner cavity of the housing 10 formed by connecting plastic plates 11, that is, the inner cavity of the housing 10 contains water and feces, and realizes anaerobic treatment of the feces. Housing 10 is provided with at least one opening for feeding and discharging. It is preferable to set the feeding port and the discharging port separately for ease of use. Larger manholes can also be provided to facilitate the cleaning of the septic tank inner cavity. The plastic plates 11 can be connected by a heat sealing process, or a flange-shaped connecting plate can be arranged on the edge of the plate body, and the plates can be screwed through the connecting plate. A sealing strip is arranged in the groove, and the sealing strip ensures that the inner cavity of the housing 10 after connection reaches the liquid-tight standard. Of course, a water-proof membrane may also be arranged in the inner cavity of the hous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com