Dual-circulation two-grade anaerobic digestion system and application thereof

An anaerobic digestion system and anaerobic digestion technology, applied in the field of dual-cycle two-stage anaerobic digestion system, can solve the problems of poor sludge degradation, low gas production, low methane production, etc., and achieve high organic load and removal of organic matter. efficiency, biogas production and high productivity, and the effect of improving operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Take dewatered sludge (water content 77.82%) and thickened sludge (water content 95.44%) from a sewage treatment plant in a certain place to make mixed sludge with water content 88.0% in the sludge blending tank. At this time, its volatile Organic solids accounted for 33.4% of the total solids.

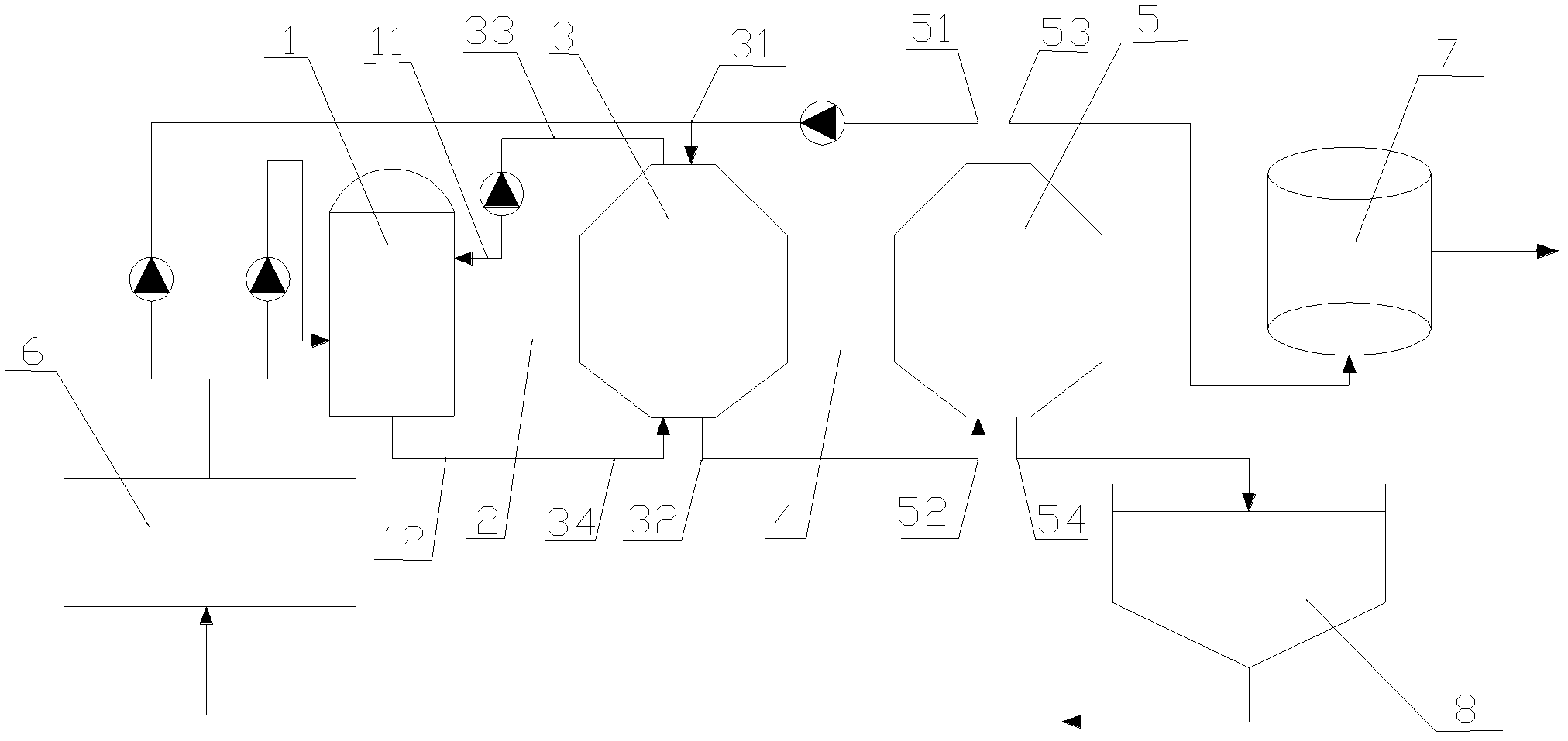

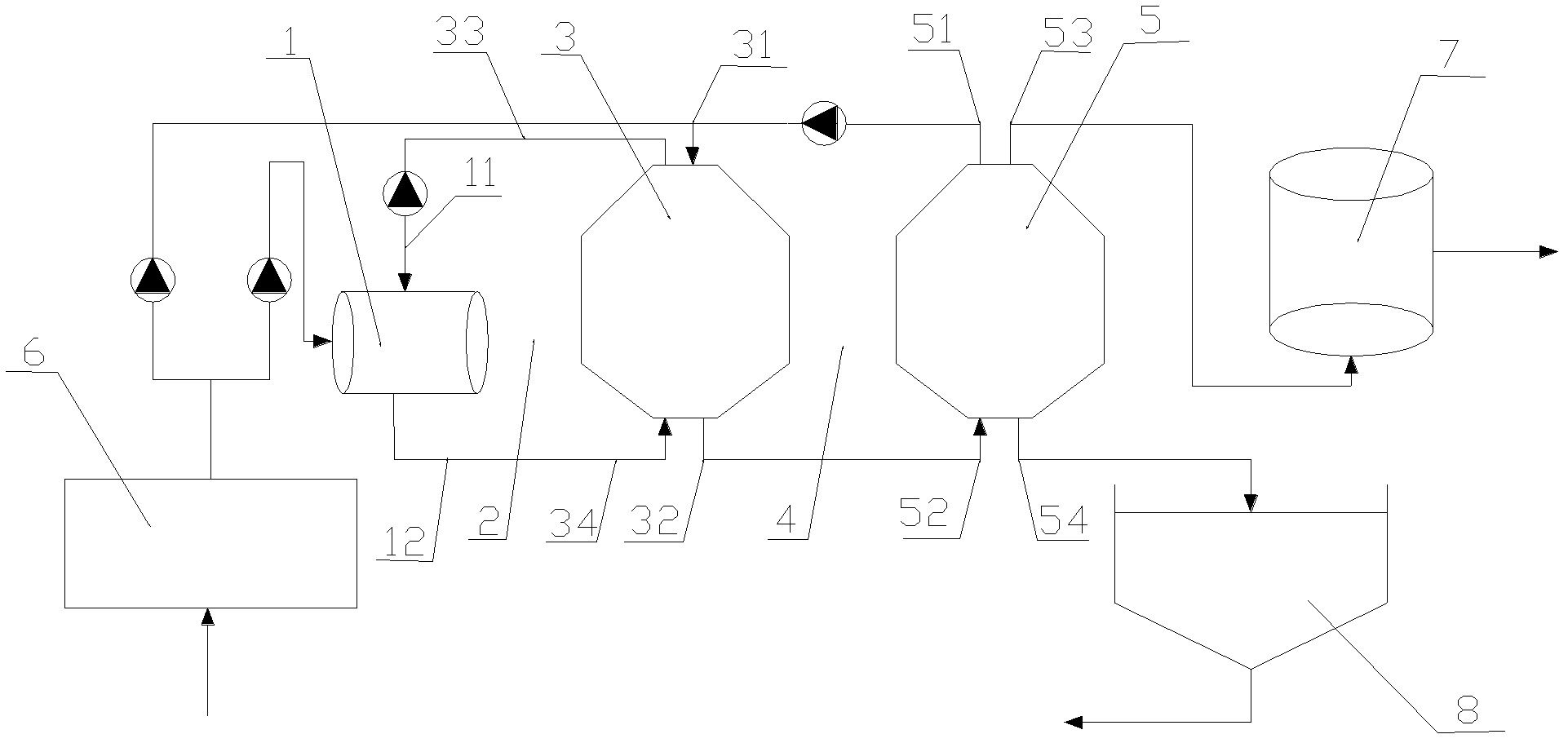

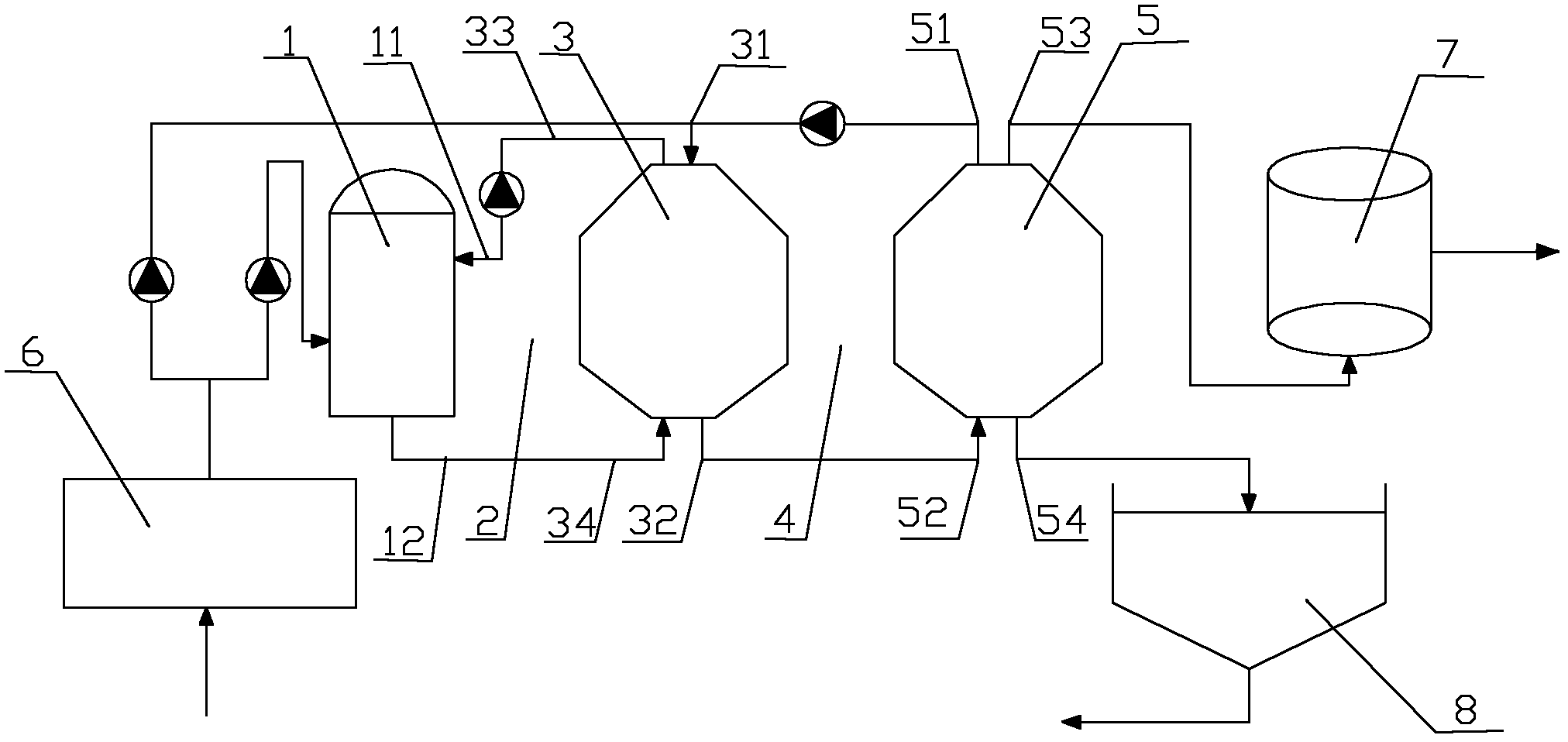

[0066] Such as figure 1 As shown, 2.5 L is pumped into the first-stage anaerobic digestion reactor 3 from the sludge blending tank 6 through the first feed port 31 by the sludge pump every day, wherein the total effective volume of the first-stage anaerobic digestion reactor 3 is 10L, discharge 500mL from the second outlet 33 every day to the heating pretreatment device 1 (reflux ratio is 5%), heat at 120 degrees for 10min, and then circulate through the second inlet 34 into the primary anaerobic digestion reaction device 3. Simultaneously in the secondary anaerobic digestion reactor 5, discharge 5L every day by the first discharge port 32; The 2.5 L feed is circulated back ...

Embodiment 2

[0068] Take dewatered sludge (water content 82.11%) and thickened sludge (water content 96.23%) from a sewage treatment plant in a certain place to make mixed sludge with water content 92.0% in the sludge blending tank. At this time, its volatile Organic solids accounted for 45.2% of the total solids.

[0069] Such as figure 1 As shown, 2.0 L is pumped into the first-stage anaerobic digestion reactor 3 from the sludge adjustment tank 6 through the first feed port 31 every day to the primary anaerobic digestion reactor 3, wherein the total effective volume of the primary anaerobic digestion reactor 3 is 6L, 700mL is discharged from the second outlet 33 every day to the heating pretreatment device (reflux ratio 12%), heated at 100 degrees for 30min, and then circulated into the primary anaerobic digestion reactor 3 through the second inlet 34 middle. Simultaneously, discharge 4L every day from the first outlet 32 to the secondary anaerobic digestion reactor 5; Circulate bac...

Embodiment 3

[0071] Take dewatered sludge (water content 79.23%) and thickened sludge (water content 99.12%) from a sewage treatment plant in a certain place to make mixed sludge with water content 98.0% in the sludge blending tank. At this time, its volatile Organic solids accounted for 60.2% of the total solids.

[0072] Such as figure 1 As shown, 2.0 L is pumped into the first-stage anaerobic digestion reactor 3 from the sludge adjustment tank 6 through the first feed port 31 every day to the primary anaerobic digestion reactor 3, wherein the total effective volume of the primary anaerobic digestion reactor 3 is 10.0L, discharge 2L per day from the second discharge port 33 into the pretreatment device (reflux ratio is 20%), heat at 90 degrees for 60 minutes, and then circulate through the second feed port 34 into the primary anaerobic digestion In reactor 3. Simultaneously, discharge 4L every day from the first outlet 32 to the secondary anaerobic digestion reactor 5; Circulate bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com