Method for producing mushroom sticks by using bark waste as main material

A technology of shiitake mushroom sticks and waste, applied in botany equipment and methods, fertilizer mixture, gardening, etc., can solve the problems of poor mycelium growth and development, waste ash, many impurities, easy to puncture the outer bag, etc., and achieve color change The effect of shortening the period, saving costs and improving the cultivation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

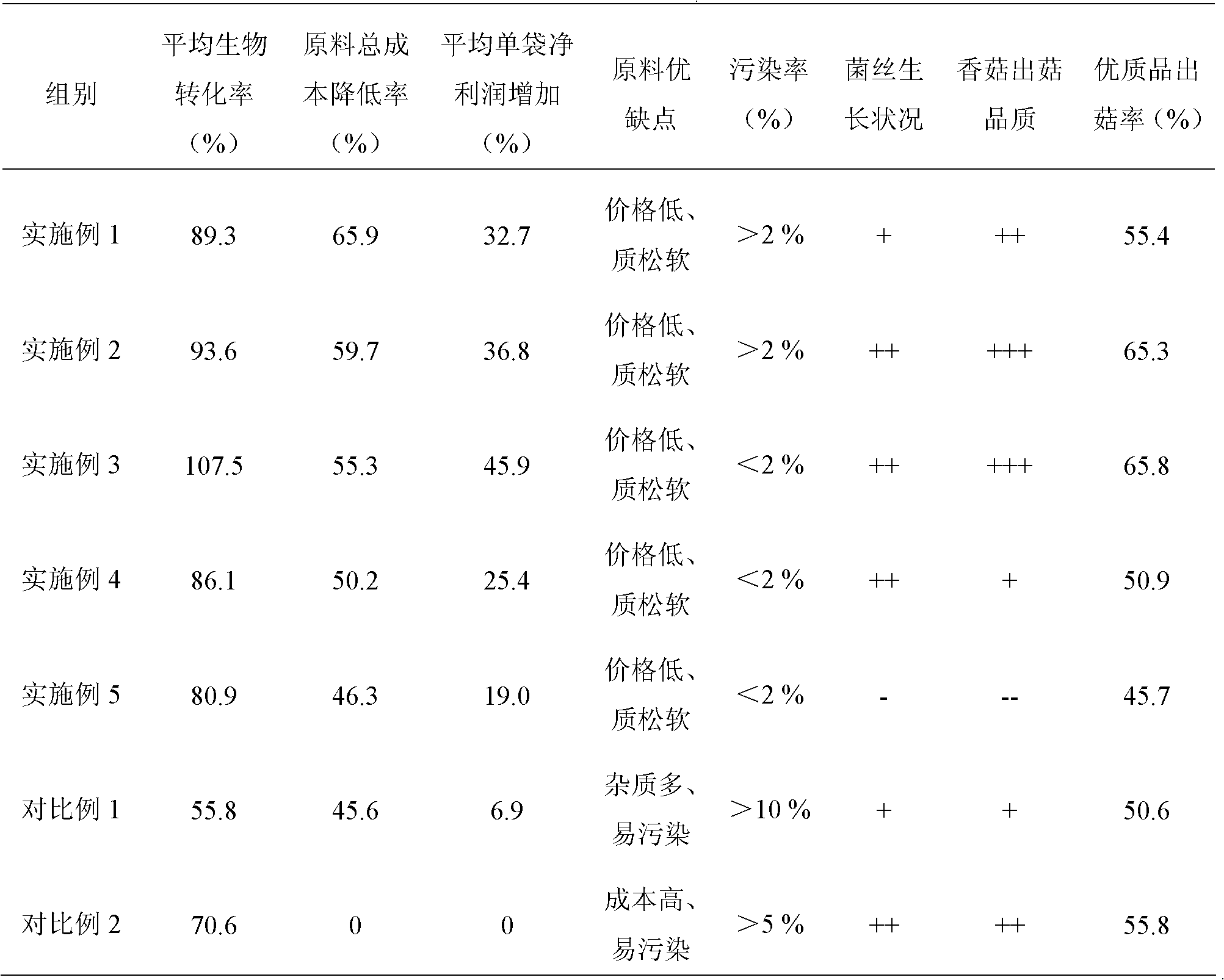

Examples

Embodiment 1

[0031] Embodiment 1: a kind of method that takes bark waste as main material to produce mushroom stick, comprises the steps:

[0032] (1) bark waste material is pulverized to 60 order, adds 1.5 kilograms of urea by every ton of bark waste material, makes its carbon-nitrogen ratio be 30: 1, stirs evenly; Chlorine dioxide disinfectant is dissolved in a certain amount of water, After stirring evenly, it is prepared into a solution with an effective concentration of chlorine dioxide of 16ppm, and then this solution is added to the water for mixing materials, and the effective concentration of chlorine dioxide in the water for mixing materials is 8ppm; then mix with water containing chlorine dioxide disinfectant Material, the water content that makes mixing material is 65wt%,

[0033] (2) The material mixed in the above step (1) is carried out to build a heap for fermentation. When the heap temperature reaches 65°C, leave it to ferment for 20 hours, turn the heap once, repeat the f...

Embodiment 2

[0036] Embodiment 2: a kind of method that takes bark waste as main material to produce mushroom stick, comprises the steps:

[0037] (1) bark waste material is pulverized to 60 order, adds 1.5 kilograms of urea by every ton of bark waste material, makes its carbon-nitrogen ratio be 30: 1, stirs evenly; Chlorine dioxide disinfectant is dissolved in a certain amount of water, After stirring evenly, it is prepared into a solution with an effective concentration of chlorine dioxide of 32ppm, and then this solution is added to the water for mixing materials, and the effective concentration of chlorine dioxide in the water for mixing materials is 16ppm; then mix with water containing chlorine dioxide disinfectant Material, the water content that makes mixing material is 65wt%,

[0038] (2) The material mixed in the above step (1) is carried out to build a heap for fermentation. When the heap temperature reaches 65°C, leave it to ferment for 20 hours, turn the heap once, repeat the ...

Embodiment 3

[0041] Embodiment 3: a kind of method that takes bark waste as main material to produce mushroom stick, comprises the steps:

[0042] (1) bark waste material is pulverized to 60 order, adds 1.5 kilograms of urea by every ton of bark waste material, makes its carbon-nitrogen ratio be 30: 1, stirs evenly; Chlorine dioxide disinfectant is dissolved in a certain amount of water, After stirring evenly, it is prepared into a solution with an effective concentration of chlorine dioxide of 48ppm, and then this solution is added to the water for mixing materials, and the effective concentration of chlorine dioxide in the water for mixing materials is 24ppm; then mix with water containing chlorine dioxide disinfectant Material, the water content that makes mixing material is 65wt%,

[0043] (2) The material mixed in the above step (1) is carried out to build a heap for fermentation. When the heap temperature reaches 65°C, leave it to ferment for 20 hours, turn the heap once, repeat the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com