Greening substrate of quarry waste muck as well as preparation method and application of greening substrate

A technology of waste slag and greening matrix, applied in the field of mine ecological environment management, can solve problems such as endangering human survival and health, poor water retention capacity, barrenness, etc., to protect land and vegetation resources, reduce the amount of waste slag and soil, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The greening substrate of quarry discarded dregs of the present invention, its preferred embodiment is:

[0021] Including quarry waste residue, organic matter, water retaining agent;

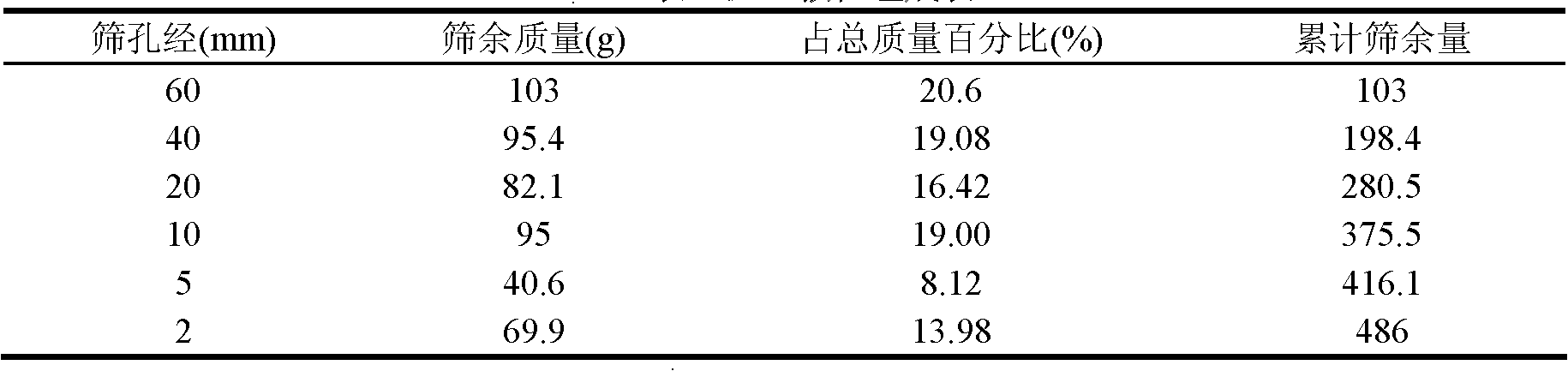

[0022] The abandoned slag in the quarry is the residual material after mining in the quarry, which is sieved manually or mechanically at 2 cm to remove the weed material;

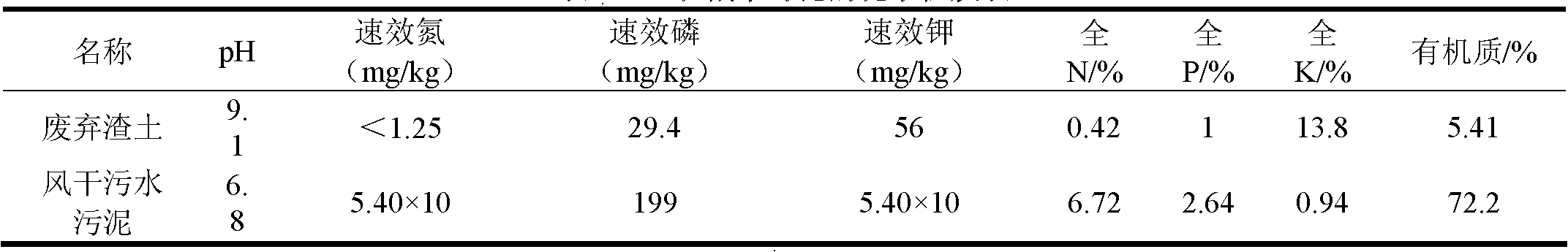

[0023] The organic matter includes one or more mixtures of sheep manure, corn stalks, Bacillus licheniformis, and air-dried sewage sludge;

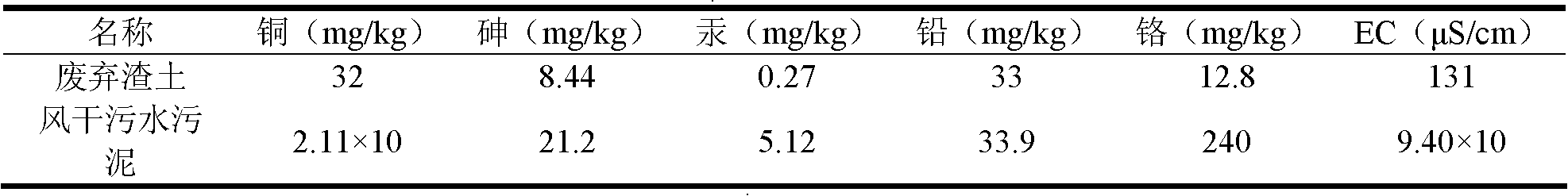

[0024] The air-dried sewage sludge is the mature sludge produced by high-temperature composting of urban sewage treatment plant sludge after secondary biological fermentation. The appearance is brown and loose, and the water content is 20-30%.

[0025] The water-retaining agent is a high-molecular polymer, and its main components are polyacrylic acid salt and polyacrylamide copolymer.

[0026] The preparation method of the greening matrix of above-mentioned quarry waste dregs o...

specific Embodiment

[0081] Experimental demonstration project in Huangyuan Village, Zhoukoudian Town, Fangshan District, Beijing——Application of quarry waste residue greening matrix on waste residue slopes and platforms.

[0082] The waste residue slope and platform of the Huangyuan quarry in Zhoukoudian Town, Fangshan District are formed by the natural accumulation of discarded loose deposits left over from quarrying. The slope is between 30° and 40°, and the application area is 10,000m 2 , The construction season is June-July.

[0083] The composition of the greening matrix of the improved dregs is: waste dregs: sewage sludge: straw = 50:40:10, and the amount of sheep manure is 70g / m 2 , water retaining agent 4g / m 2 , Bacillus licheniformis fertilizer 30g / m 2 , plant Amorpha fruticosa, tall fescue, and alfalfa, adopt the method of whole, partial greening and planting bag greening on the slope and platform of the waste residue to prepare the mixture of matrix and seeds according to the above m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com