Special halogen-free environment-friendly flame retardant for polypropylene

A polypropylene and flame retardant technology, applied in the field of flame retardants, can solve the problems of poor compatibility, large addition amount, and decline in polymer properties, and achieve the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A halogen-free environmentally friendly flame retardant applied to polypropylene, made of the following raw materials in parts by weight: epoxy resin coated ammonium polyphosphate 47, poly 2-ethylenediamine-4-phenoxy-1, 3,5-triazine 38, nano-montmorillonite 10, zinc oxide 4, pure powder polytetrafluoroethylene 1, polymethylphenylsiloxane 2.

[0017] Preparation method: Weigh the raw materials according to the above parts by weight, coat epoxy resin with ammonium polyphosphate, poly 2-ethylenediamine-4-phenoxy-1,3,5-triazine, nano-montmorillonite, oxidized Add zinc and pure powder polytetrafluoroethylene into a high-speed mixer and mix at high speed, heat up to 85°C, add polymethylphenylsiloxane, lower the temperature and cool to 40°C, crush, sieve, and pack to obtain the product of the present invention .

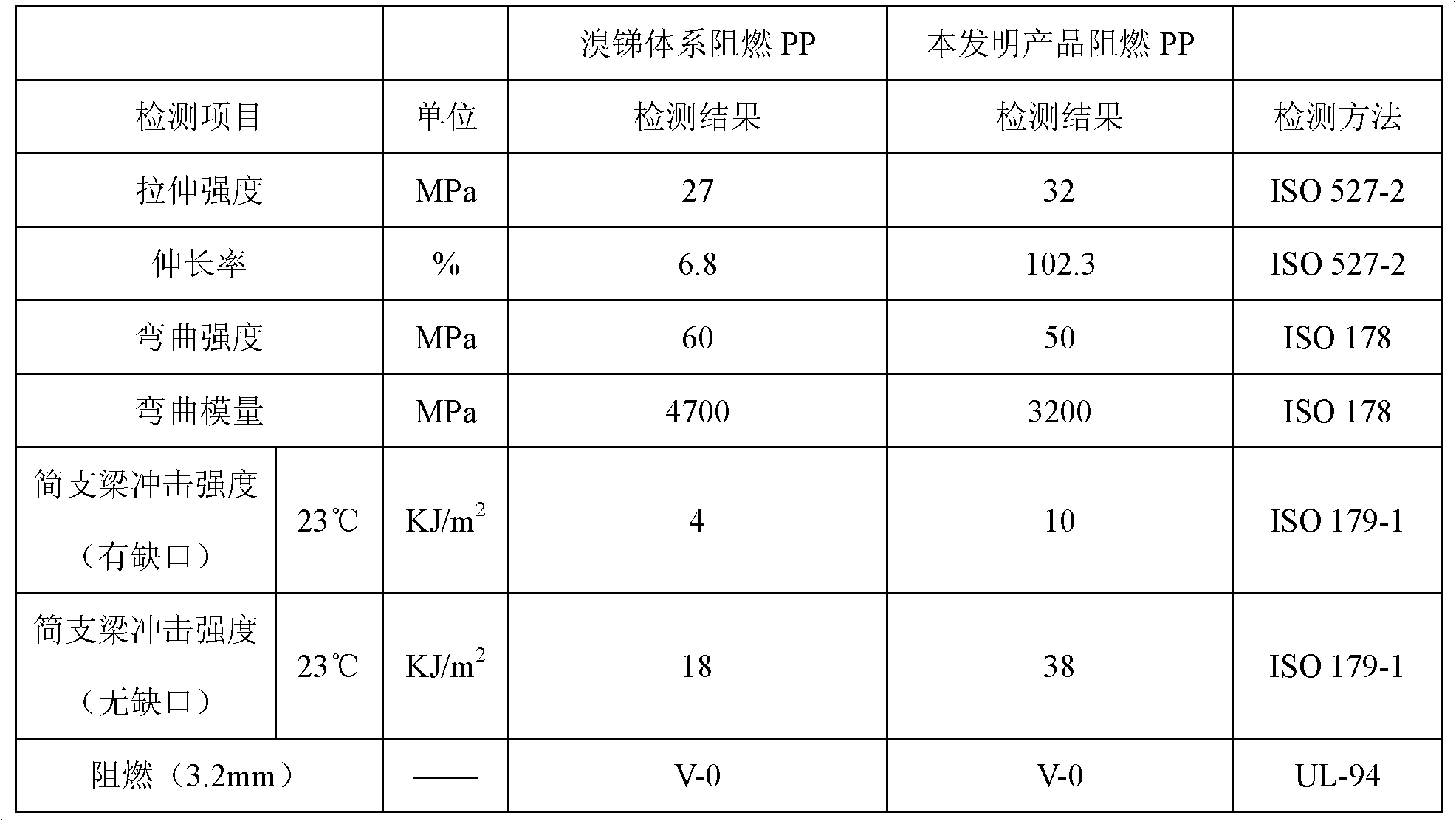

[0018] The obtained product halogen-free environmentally friendly flame retardant was applied to polypropylene, and compared with the flame retardant effect of the ...

Embodiment 2

[0024] A special halogen-free environmentally friendly flame retardant for polypropylene, made of the following raw materials in parts by weight: epoxy resin coated ammonium polyphosphate 45, polyethylene terephthalamide 37.8, 4A molecular sieve 11, magnesium oxide 5 , Pure powder polytetrafluoroethylene 1.2, polymethylphenylsiloxane 3.5.

[0025] Preparation method: Weigh the raw materials according to the above weight parts, add epoxy resin-coated ammonium polyphosphate, polyethylene terephthalamide, 4A molecular sieve, magnesium oxide and pure powder polytetrafluoroethylene into a high-speed mixer Mix, heat up to 90°C, add polymethylphenylsiloxane, lower the temperature and cool to 45°C, then pulverize, sieve, and package to obtain the product of the present invention.

Embodiment 3

[0027] A special halogen-free environmentally friendly flame retardant for polypropylene, made of the following raw materials in parts by weight: silane-coated ammonium polyphosphate 58, tripentaerythritol 30, aluminum magnesium silicate 8, zinc borate 3, pure powder type polytetrafluoroethylene Vinyl 1, Polymethylphenylsiloxane 4.

[0028] Preparation method: Weigh the raw materials according to the above weight parts, add silane-coated ammonium polyphosphate, tripentaerythritol, aluminum magnesium silicate, zinc borate and pure powder polytetrafluoroethylene into a high-speed mixer and mix at high speed, heat up to 120°C, Add polymethylphenylsiloxane, lower the temperature and cool to 50°C, then pulverize, sieve and pack to obtain the product of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com