Wear-resistant halogen-free flame-retardant elastomer complex and preparation method thereof

A technology of elastomers and composites, applied in the direction of conductors, insulated conductors, electrical components, etc., to achieve the effects of easy extrusion molding processing, good wear resistance, and good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

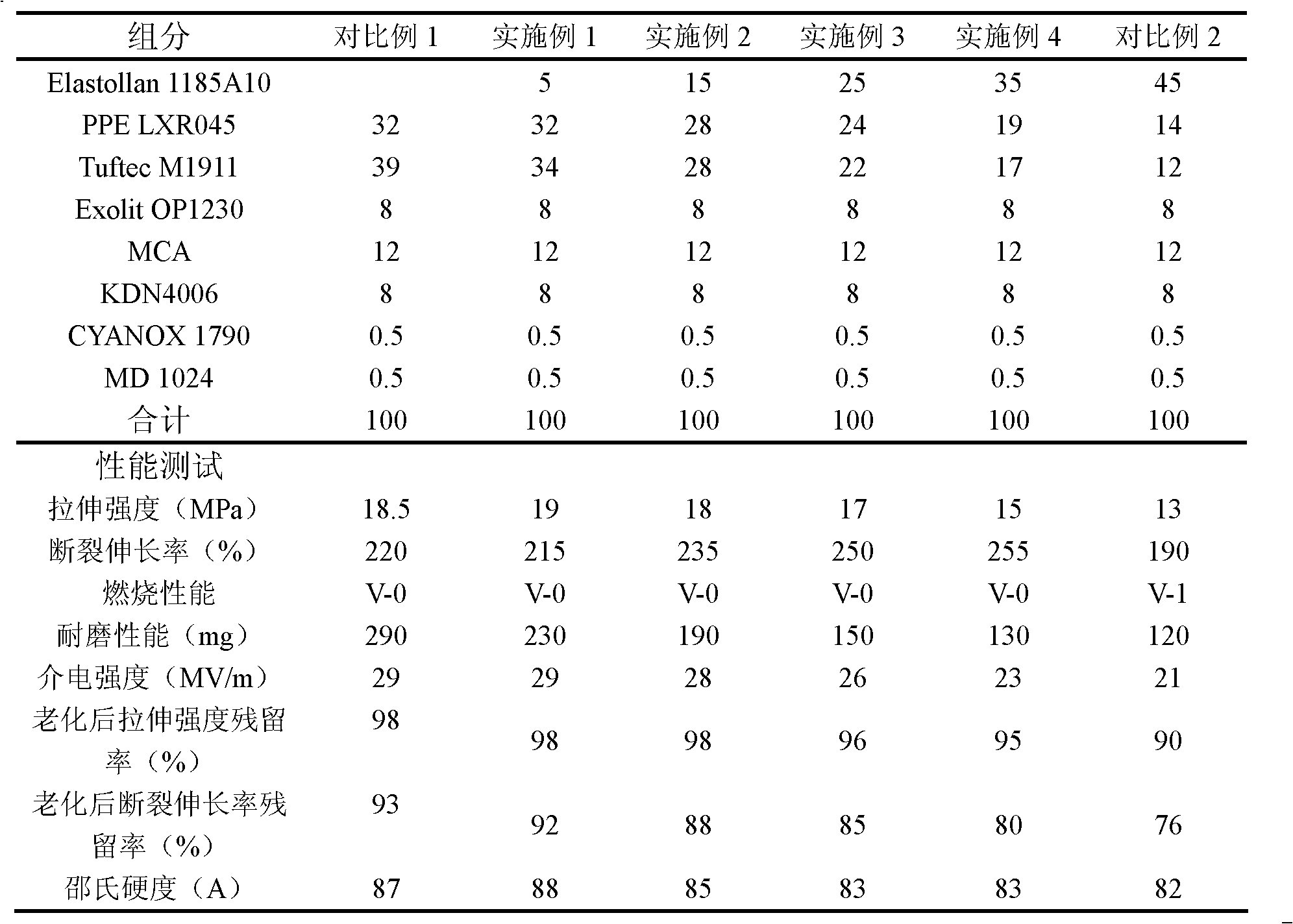

[0028] The present invention is further explained below in conjunction with the examples, but the examples do not limit the present invention in any form.

[0029] The preparation method of the halogen-free flame-retardant elastomer compound of the present invention comprises the following steps: first, the polyurethane elastomer resin, polyphenylene ether resin, compatibilizer, flame retardant, plasticizer and antioxidant are passed through a high-speed mixer After dispersion and mixing, it is melted, kneaded, extruded, cooled, dried, pelletized and packaged through a twin-screw extruder. The temperature in each zone of the screw should be kept at 245°C, the aspect ratio of the twin-screw extruder is 40, and the screw speed is 350 rpm.

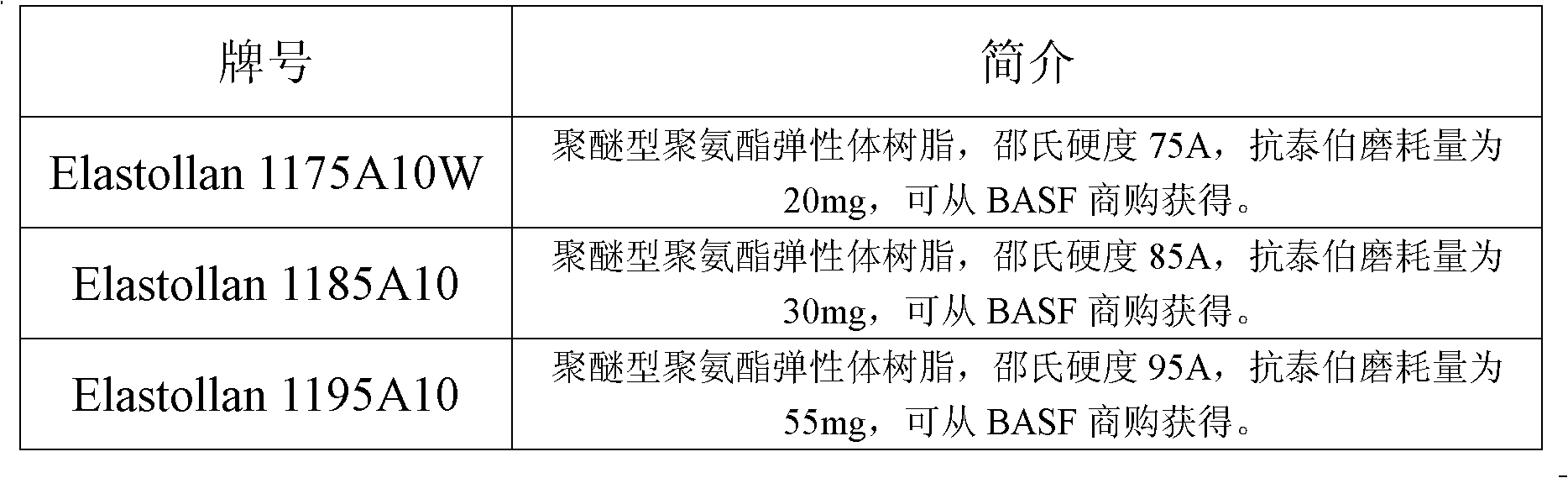

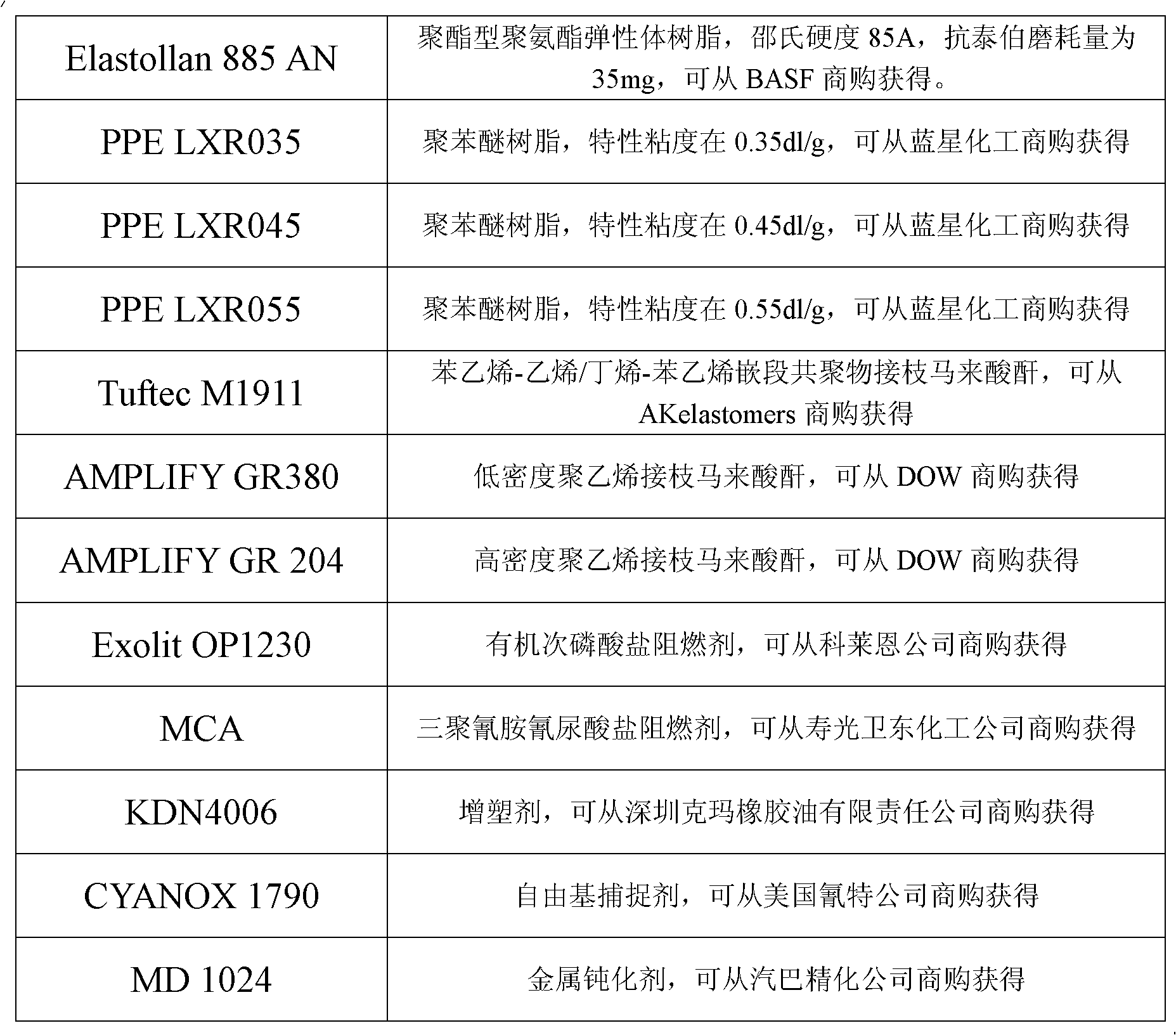

[0030] According to above-mentioned preparation method, embodiment and comparative example adopt raw material as follows:

[0031]

[0032]

[0033] Each test is carried out according to the following standards:

[0034] Tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com