Preparation method for ultrathin pigment paste used for coloring viscose filament fiber dope

A technology of dope coloring and viscose filaments, which is applied to fibrous fillers, artificial filaments made of viscose, organic dyes, etc., which can solve the problems of flocculation, uneven particle size distribution and poor filterability of viscose spinning solution and other problems, to achieve good color fastness, small particle size and adhesion, and small color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

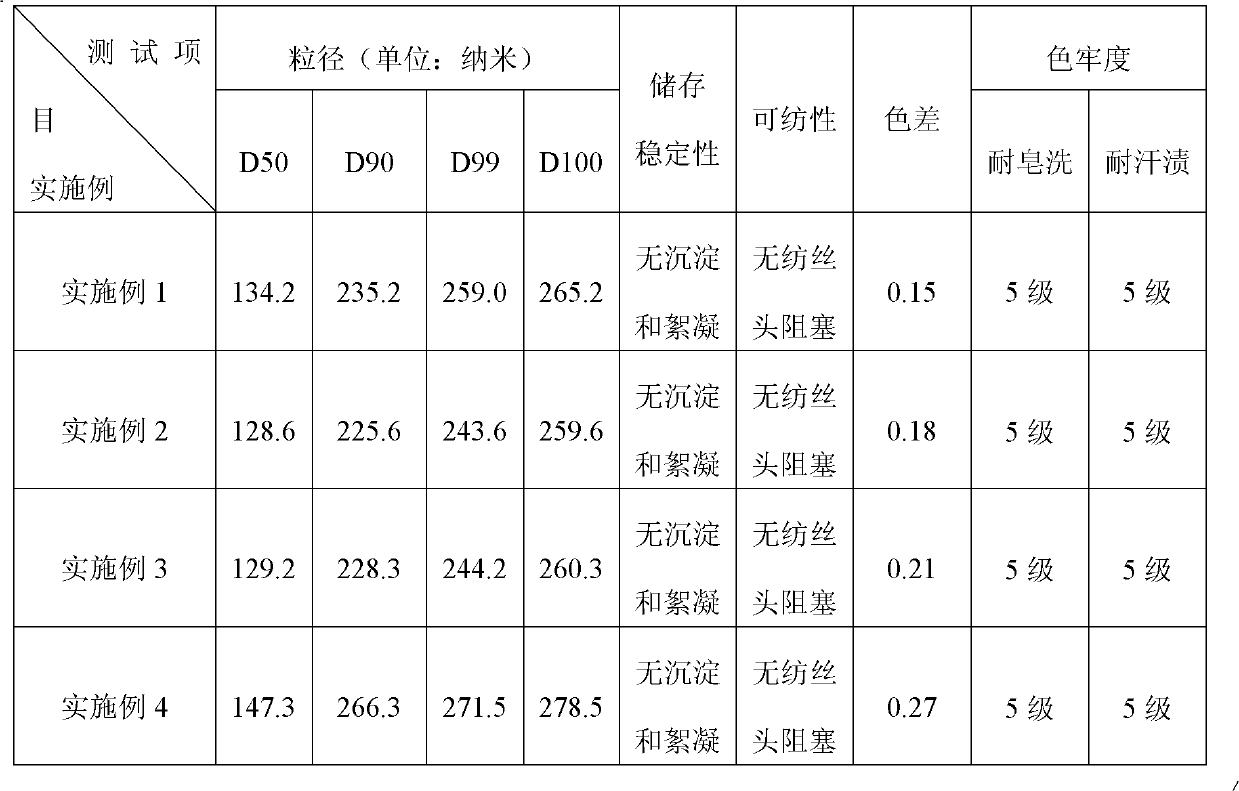

Examples

Embodiment 1

[0019] Take 20kg of carbon black, 1.2kg of polymerizable dispersant AHPS, and 178.8kg of deionized water, place them in a sand mill and grind them at a speed of 1800r / min for 3 hours to prepare a black ultrafine pigment water-based dispersion system, and then add dropwise Styrene 0.6kg continues to grind 1.5 hours, transfers in the reactor, adopts cobalt 60-gamma ray radiation, and radiation agent consumption is about 300,000 curies, and radiation time is 30 minutes, takes out material and filters with the microporous membrane of 500nm then, namely Black superfine pigment paste for viscose filament stock solution coloring can be obtained.

Embodiment 2

[0021] Take 30kg of C.I. Pigment Yellow 93 powder, 3kg of polymerizable dispersant HMPS, and 167kg of deionized water, place them in a sand mill and grind them at a speed of 2000r / min for 4 hours to obtain a yellow ultrafine pigment water-based dispersion system, and then add them to Add 1.2kg of glycidyl acrylate dropwise and continue to grind for 1.3 hours, transfer to the reactor, adopt cobalt 60-γ ray radiation, the radiation agent consumption is about 600,000 curies, and the radiation time is 120 minutes, filter with a 500nm microporous membrane, The yellow superfine pigment color paste for coloring the viscose long fiber stock solution can be obtained.

Embodiment 3

[0023] Get C.I. Pigment Blue 60 powder 40kg, polymerizable dispersant DMHB8kg, deionized water 152kg, place in a sand mill and grind for 5 hours at a speed of 2500r / min to prepare a blue ultrafine pigment water-based dispersion system, and then add it to the Add dropwise 1.5kg of methyl methacrylate, 0.5kg of lauryl acrylate, continue to grind for 1.2 hours, transfer to the reactor, and adopt cobalt 60-γ ray radiation. The radiation dose is about 20,000 curies, and the radiation time is 30 Minutes, filter with a 500nm microporous membrane to get the blue ultrafine pigment paste for coloring the viscose filament stock solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com