Method for preparing UV (ultraviolet)-curable high-temperature-resistant and corrosion-resistant organic silicon/silica hybrid coating

A technology of silicon dioxide and ultraviolet light, which is applied in coatings, anti-corrosion coatings, etc., to achieve the effect of improving corrosion resistance and comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

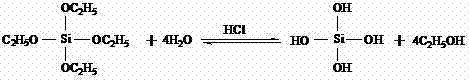

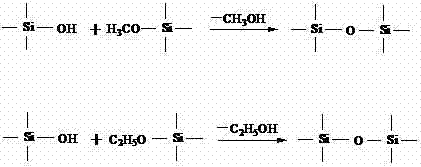

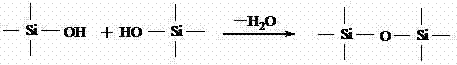

Method used

Image

Examples

Embodiment 1

[0030] At room temperature, add absolute ethanol, hydrochloric acid and distilled water dropwise to quantitative ethyl orthosilicate sequentially according to the measured number, react for 5min~85min, and then add quantitative methyltriethoxysilane, diphenyldimethylsilane The mixed solution of oxysilane, γ-methacryloxysilane and free radical photoinitiator, reacted for 25min~3h, heated to 50~80℃, condensed and refluxed for 1h~6h to obtain colorless and transparent UV-curable The organic silicon / silicon dioxide hybrid sol, after cooling to room temperature, seal and stand for later use, apply the sealed and static hybrid sol on the substrate by brush coating, and after the solvent volatilizes, carry out ultraviolet light curing to obtain organic silicon / silicon dioxide hybrid coating, and after UV curing for 60s, a silicone / silicon dioxide hybrid coating was obtained.

[0031] The properties of the coating are as follows: the hardness is 0.8513, the flexibility is 1mm, the ad...

Embodiment 2

[0033] At room temperature, add absolute ethanol, hydrochloric acid and distilled water dropwise to quantitative ethyl orthosilicate sequentially according to the measured number, react for 5min~85min, and then add quantitative methyltriethoxysilane, diphenyldimethylsilane The mixed solution of oxysilane, γ-methacryloxysilane and free radical photoinitiator, reacted for 25min~3h, heated to 50~80℃, condensed and refluxed for 1h~6h to obtain colorless and transparent UV-curable The organic silicon / silicon dioxide hybrid sol, after cooling to room temperature, seal and stand for later use, apply the sealed and static hybrid sol on the substrate by brush coating, and after the solvent volatilizes, carry out ultraviolet light curing to obtain organic silicon / silicon dioxide hybrid coating, and after UV curing for 60s, a silicone / silicon dioxide hybrid coating was obtained.

[0034]The properties of the coating are as follows: the hardness is 0.8961, the flexibility is 1mm, the adh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com