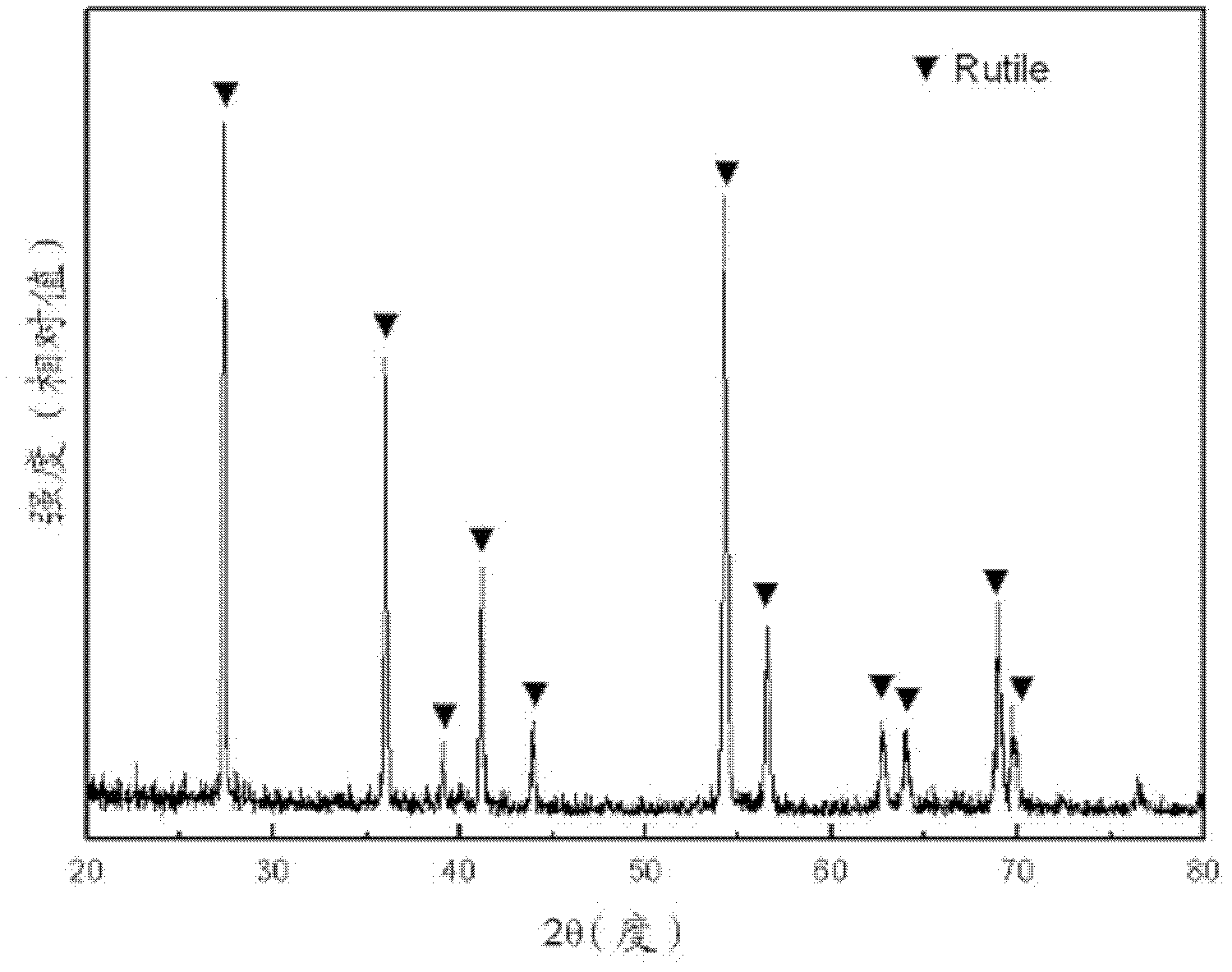

Microarc oxidation preparation method of pure rutile phase titanium dioxide electrochromism film

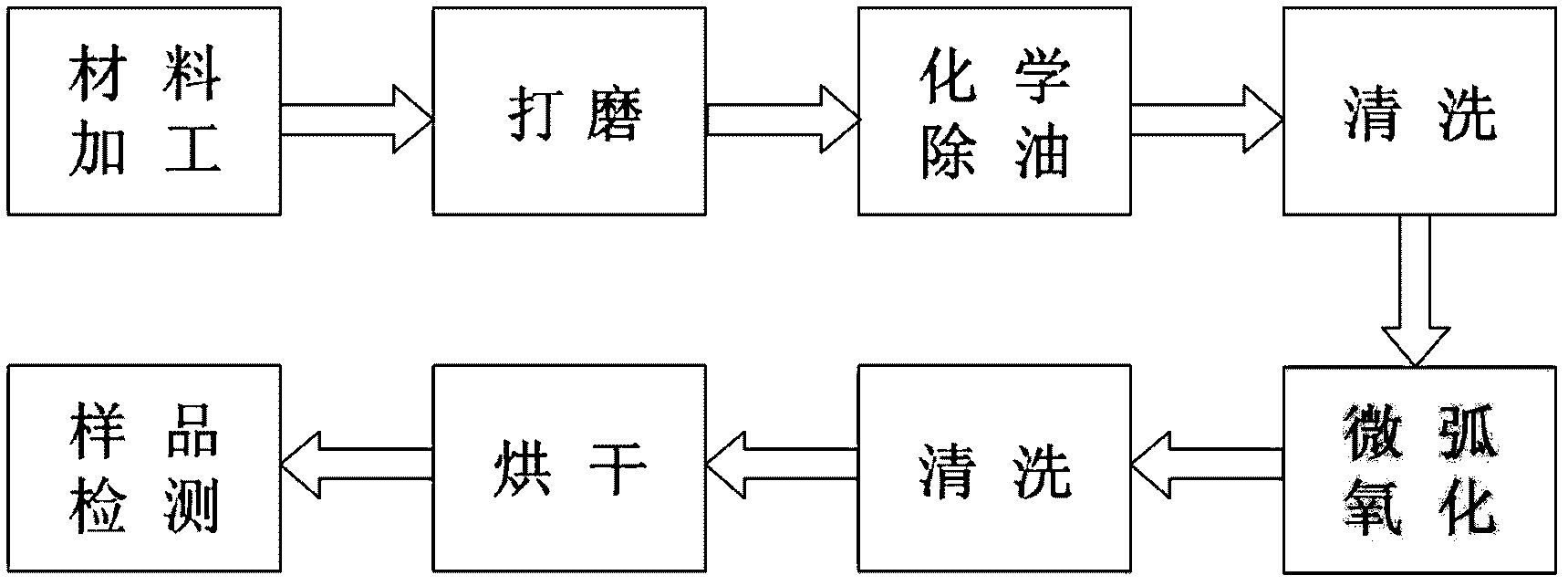

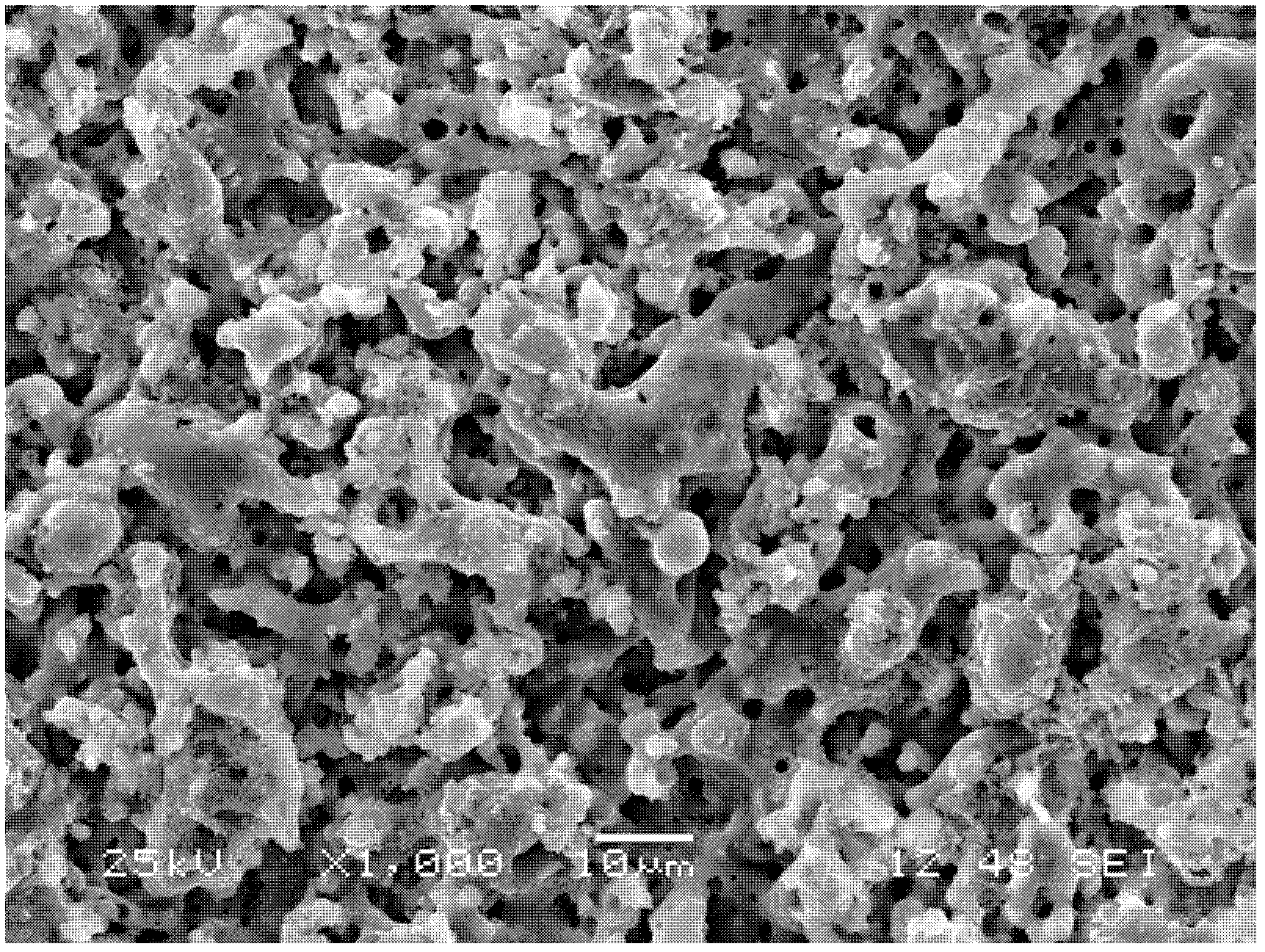

A technology of electrochromic film and micro-arc oxidation, which is applied in the field of electrochromic film layer of pure rutile phase titanium dioxide prepared by micro-arc oxidation, to achieve the effect of high thickness, short processing time and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The titanium or its alloy samples are polished and cleaned, placed in acetone for ultrasonic cleaning to degrease, washed with deionized water, and then dried for use. Take 1 L of deionized water and divide it into 3 parts, and dissolve the mixture of 0.12 mol sodium aluminate, 0.015 mol aluminum sulfate, 0.04 mol sodium phosphate and 0.03 mol sodium silicate in these 3 parts of aqueous solution respectively. Mix and stir the 3 solutions in the order of sodium aluminate, aluminum sulfate, sodium phosphate and sodium silicate to make a colloid treatment solution. The prepared solution is placed in the treatment liquid tank, and the titanium or its alloy sample is connected to the anode of the micro-arc oxidation power supply and immersed in the treatment liquid. Micro-arc oxidation for 15 minutes (electrical parameters are as follows: anode pulse voltage: 450V; pulse frequency: 1000Hz; pulse duty ratio: 20%). After the treatment, the sample was washed and dried to comple...

Embodiment 2

[0034] The titanium or its alloy samples are polished and cleaned, placed in acetone for ultrasonic cleaning to degrease, washed with deionized water, and then dried for use. Take 1 L of deionized water and divide it into 2 parts, and dissolve 0.24 mol of sodium aluminate and 0.03 mol of aluminum sulfate in these 2 parts of aqueous solution respectively. Mix the 2 parts of the solution and stir well to make a colloidal treatment solution. The prepared solution is placed in the treatment liquid tank, and the titanium or its alloy sample is connected to the anode of the micro-arc oxidation power supply and immersed in the treatment liquid. Micro-arc oxidation for 10 minutes (electric parameters are as follows: anode pulse voltage: 350V; pulse frequency: 1000Hz; pulse duty ratio: 20%). After the treatment, the sample was washed and dried to complete the preparation.

Embodiment 3

[0036] The titanium or its alloy samples are polished and cleaned, placed in acetone for ultrasonic cleaning to degrease, washed with deionized water, and then dried for use. Take 1L of deionized water and divide it into 3 parts. Dissolve 0.06mol of sodium aluminate, 0.007mol of aluminum sulfate and 0.04mol of sodium phosphate in these 3 parts of aqueous solution respectively. According to the sequence of sodium aluminate, aluminum sulfate and sodium phosphate, the 3 parts of the solution were mixed and stirred evenly to make a colloidal treatment solution. The prepared solution is placed in the treatment liquid tank, and the titanium or its alloy sample is connected to the anode of the micro-arc oxidation power supply and immersed in the treatment liquid. Micro-arc oxidation for 30 minutes (electrical parameters are as follows: anode pulse voltage: 550V; pulse frequency: 1000Hz; pulse duty ratio: 20%). After the treatment, the sample was washed and dried to complete the prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com