Production process of fluoride-free waterproof breathable knitted fabric

A technology of knitted fabrics and production technology, which is applied in textiles and papermaking, dyeing, fiber treatment, etc. It can solve the problems of non-breathable micropores, difficult care, high-temperature drying or ironing, etc., and achieve superior waterproof and breathable properties And washing resistance, long-lasting and stable function, soft and smooth hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A production process of fluorine-free waterproof and breathable knitted fabrics, including original preparation→cloth sorting→pretreatment process→dyeing process→softening→wet opening→drying process→setting finishing process→finished product inspection / packaging.

[0021] The raw material is prepared by using Italian Orli to weave the gray fabric of the single-sided sweater structure on the single-jersey circular knitting machine; the weaving raw material of the gray fabric is 100% cotton, the veil JC32S (Siro spinning), the bottom yarn C16S X2, the weaving parameters: The rough weight is 280g / m 2 , the blank width is 110×2cm, the JC32S thread length is 38cm / tie wool 45cm / 100G, and the C16S / 2 thread length is 18.5cm / 100G. 5.2.1

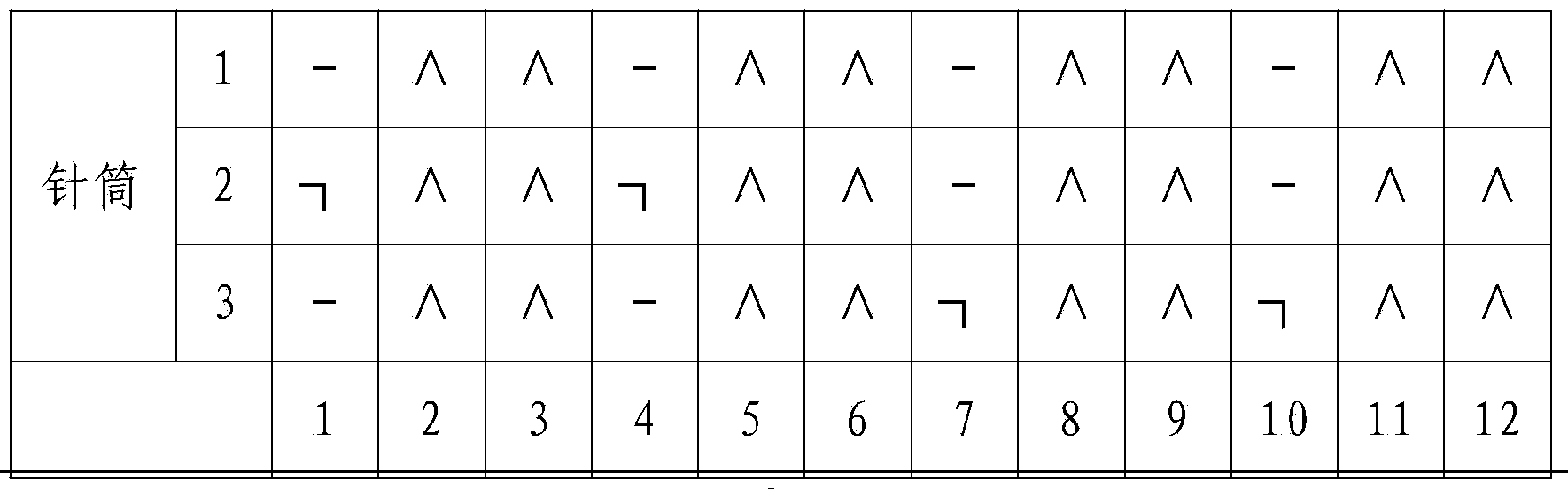

[0022] Knitting needle arrangement: needle cylinder 1213

[0023] Triangular arrangement:

[0024]

[0025] ∧: Needle cylinder loop forming triangle ┐: Needle cylinder pile loop triangle-: Needle cylinder floating thread triangle yarn arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com