Preparation technology for craft paper and paint for coating craft paper

A preparation process, kraft paperboard technology, applied in paper coating, pulp raw material addition process, papermaking, etc., can solve the problems of poor printing performance, quality that cannot meet people's needs, easy to yellow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

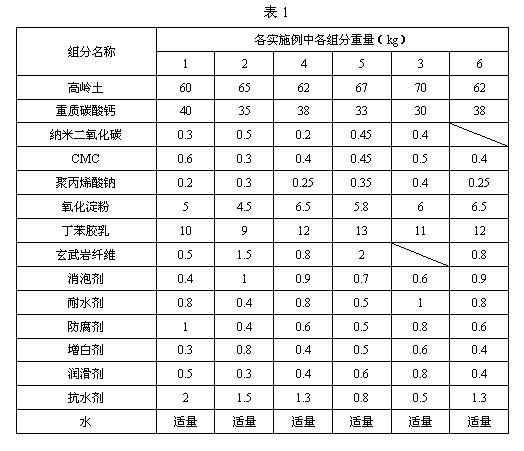

Embodiment 1

[0024] A preparation process for kraft cardboard, comprising: preparation of surface layer slurry, liner layer slurry and bottom layer slurry; surface layer slurry, liner layer slurry and bottom layer slurry are prepared by papermaking; base paper is pressed, dried and The pre-calendering process; the coating process of base paper; the post-treatment process after coating; the coating process of base paper includes the following steps:

[0025] (1) Pigment dispersion: add an appropriate amount of water into the disperser, and adjust the pH of the water to 6.0 by adding sodium hydroxide or ammonia water, then add sodium polyacrylate and stir at low speed for 7 minutes, then add kaolin and stir at high speed for 10 minutes, then add kaolin and heavy calcium carbonate totaling 100 parts, add the corresponding heavy calcium carbonate, and stir at high speed for 5 minutes, wherein the particle size of kaolin is less than or equal to 2 μm, wherein the kaolin with a particle size of l...

Embodiment 2

[0031] A preparation process for kraft cardboard, comprising: preparation of surface layer slurry, liner layer slurry and bottom layer slurry; surface layer slurry, liner layer slurry and bottom layer slurry are prepared by papermaking; base paper is pressed, dried and The pre-calendering process; the coating process of base paper; the post-treatment process after coating; the coating process of base paper includes the following steps:

[0032] (1) Pigment dispersion: add an appropriate amount of water into the disperser, and adjust the pH of the water to 6.3 by adding sodium hydroxide or ammonia water, then add sodium polyacrylate and stir at low speed for 10 minutes, then add kaolin and stir at high speed for 5 minutes, then add kaolin and heavy calcium carbonate totaling 100 parts, add the corresponding heavy calcium carbonate, and stir at a high speed for 7 minutes, wherein the particle size of kaolin is less than or equal to 2 μm, and the kaolin with a particle size of les...

Embodiment 3

[0038] A preparation process for kraft cardboard, comprising: preparation of surface layer slurry, liner layer slurry and bottom layer slurry; surface layer slurry, liner layer slurry and bottom layer slurry are prepared by papermaking; base paper is pressed, dried and The pre-calendering process; the coating process of base paper; the post-treatment process after coating; the coating process of base paper includes the following steps:

[0039] (1) Pigment dispersion: Add an appropriate amount of water into the disperser, and adjust the pH of the water to 6.6 by adding sodium hydroxide or ammonia water, then add sodium polyacrylate and stir at low speed for 5 minutes, then add kaolin and stir at high speed for 9 minutes, then add kaolin and heavy calcium carbonate totaling 100 parts, add the corresponding heavy calcium carbonate, and stir at a high speed for 10 minutes, wherein the particle size of kaolin is less than or equal to 2 μm, and the kaolin with a particle size of les...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com