Aerodynamic engine assembly

An aerodynamic and engine technology, applied in electric vehicles, electrical components, exhaust devices, etc., can solve the problems of low utilization rate of gas distribution devices and energy, insufficient utilization of compressed air, failure to achieve energy saving, etc., to achieve maximum utilization High efficiency, low cost, and work-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

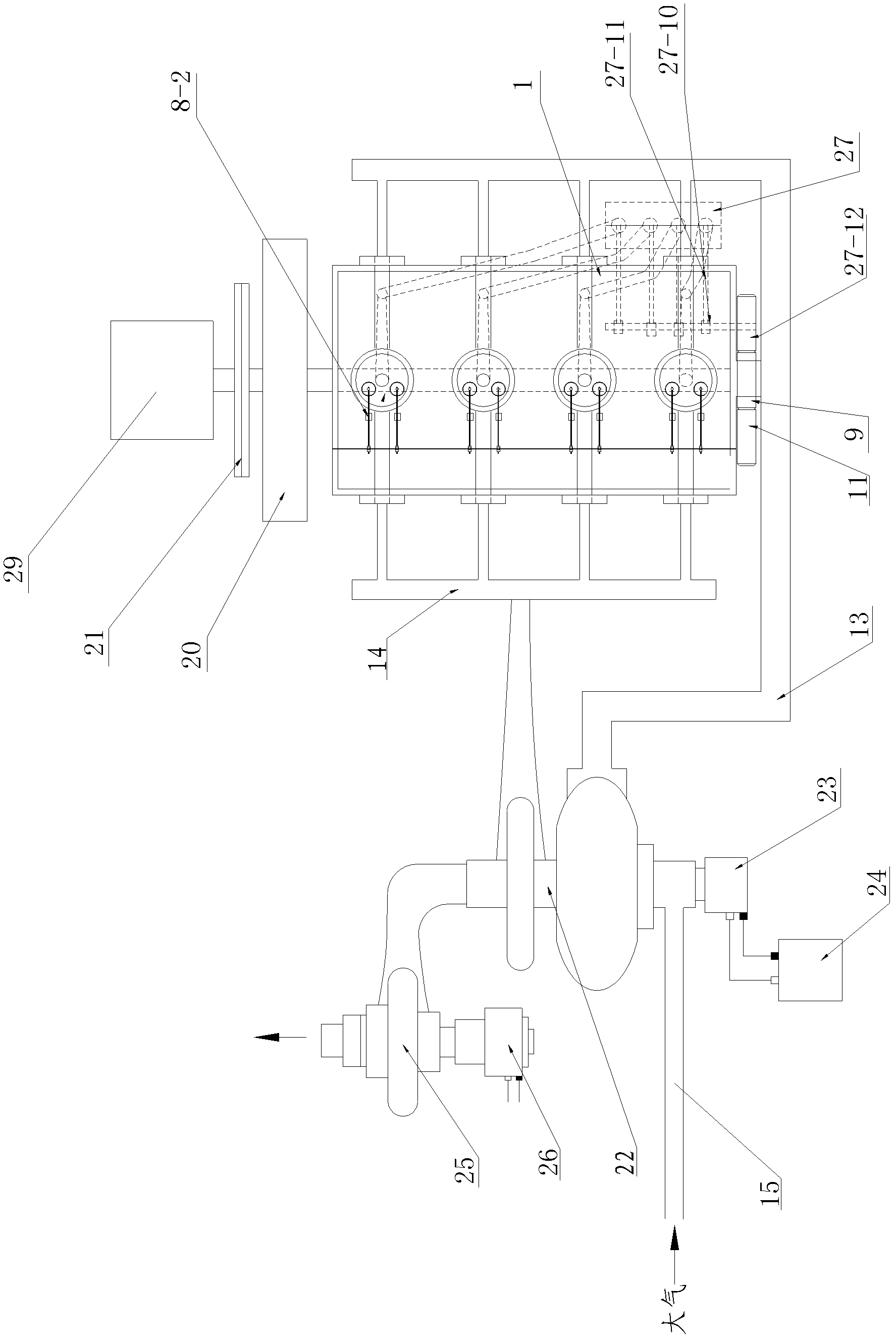

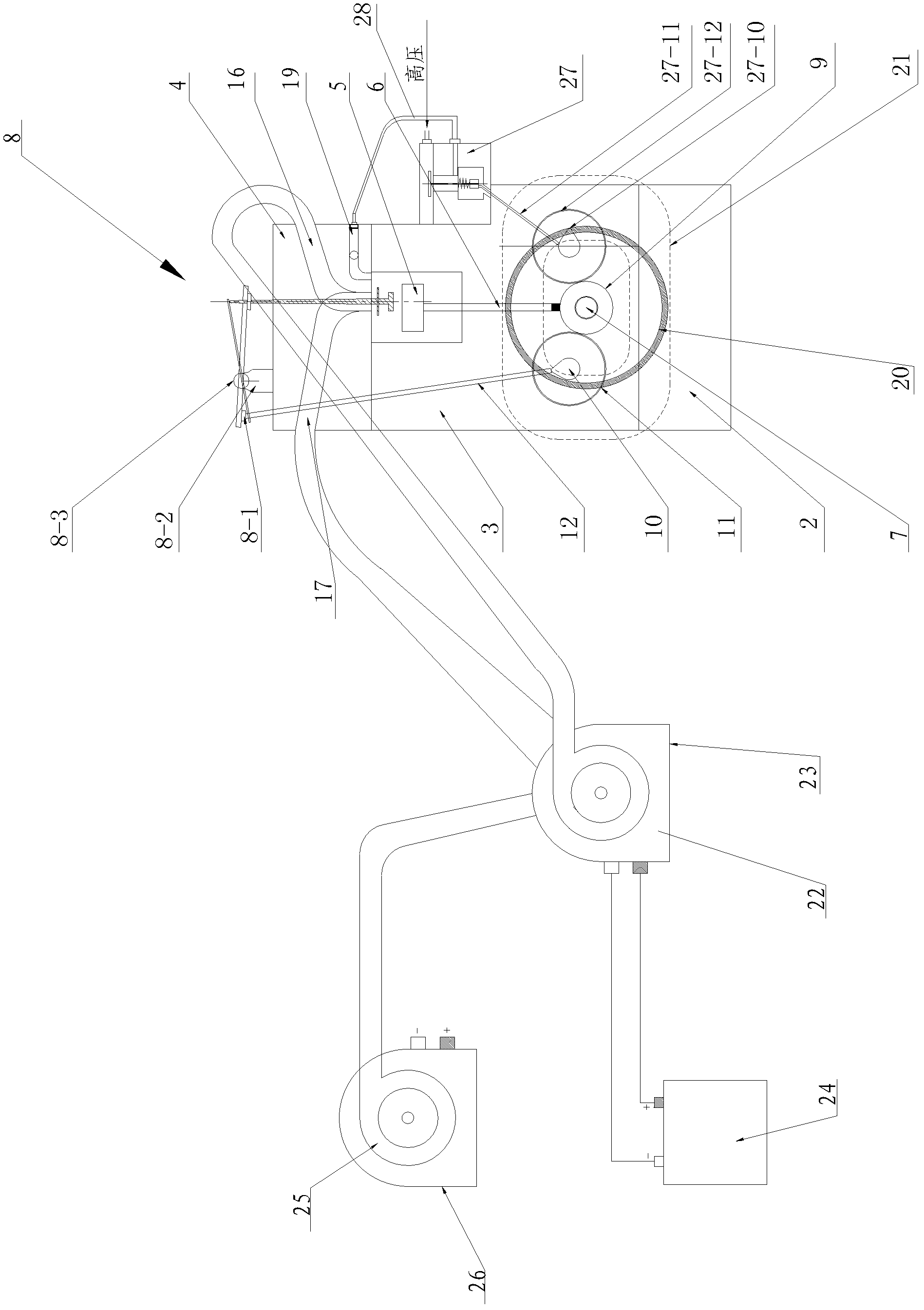

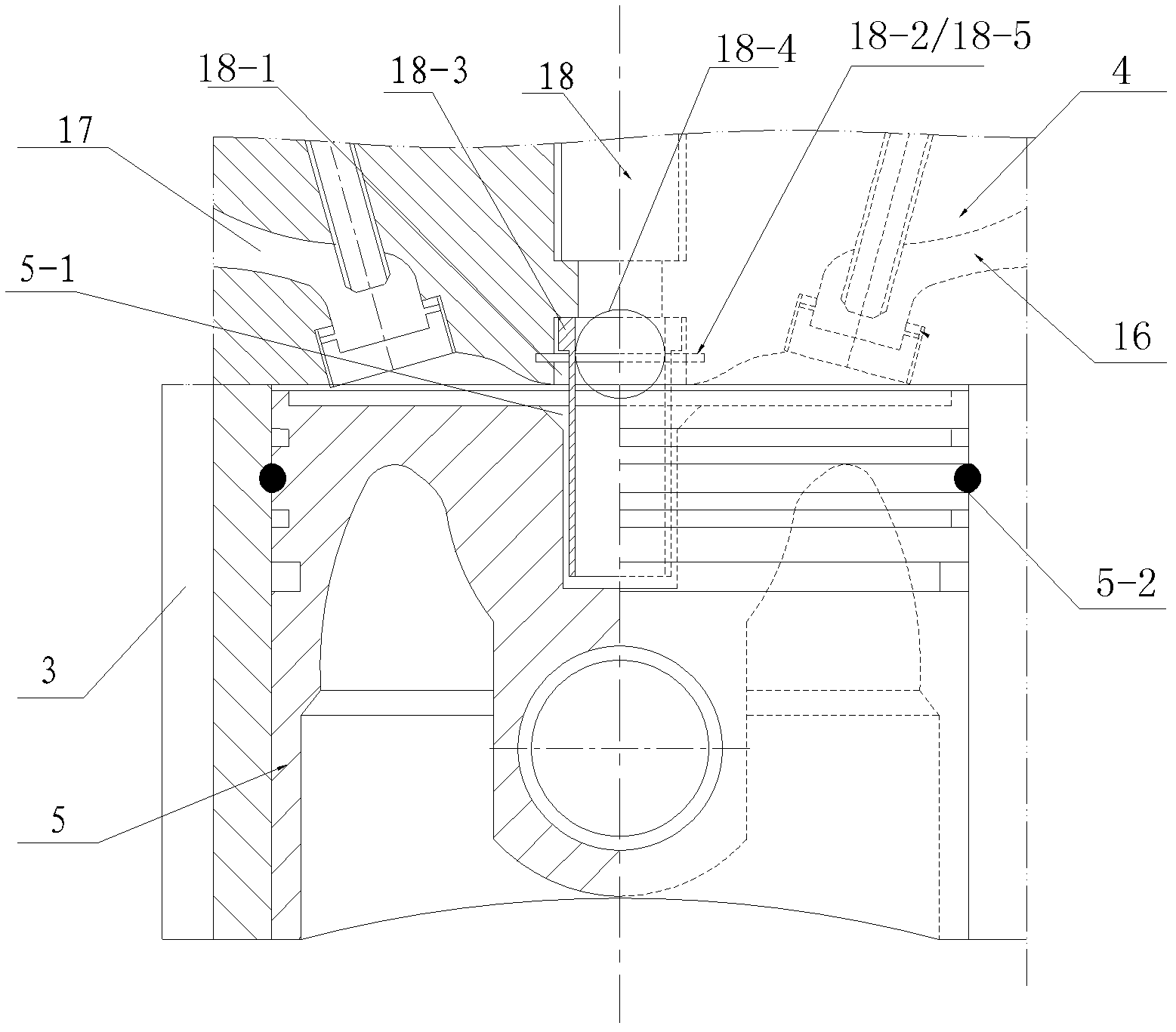

[0039] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0040] see figure 1 and figure 2 , an aerodynamic engine assembly, comprising an engine case 1, a bottom case 2, a cylinder block 3, a cylinder head 4, a piston 5 and a connecting rod 6 installed in the cylinder body, a crankshaft 7, and a valve assembly 8, on which the crankshaft 7 is installed Crankshaft timing gear 9 is arranged, and crankshaft timing gear 9 meshes with the timing gear 11 installed on the camshaft 10, and the camshaft 10 is installed on the engine housing 1, and the cam of the camshaft 10 is hinged with a push rod 12. The upper part of the ejector rod 12 is connected to the valve assembly 8, the valve assembly 8 mainly includes the rocker back 8-1 connected to the ejector rod 12, and the rocker back 8-1 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com