Box for rapidly determining formaldehyde in indoor air, and passive absorption manufacturing method

A technology for indoor air and formaldehyde absorption, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the impact on chemical indicators, etc. It can solve the problems of slow absorption and reaction speed, poor consistency of detection reagents, and production Process complexity and other issues, to achieve the effect of reducing absorption time, solving pollution problems, and preventing powder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

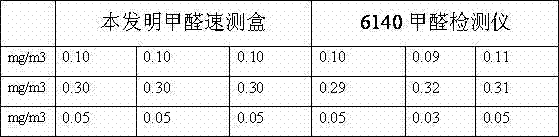

Examples

example

[0013] First, use a balance to accurately weigh 1.30 grams of sodium metabisulfite (Na2S2O5) into a 100 ml beaker, add 20 ml of pure water, stir and dissolve with a stirring bar, then add 20.0 g of glycerin, then add 80 ml of pure water, and stir completely Dissolved, this solution acts as a formaldehyde absorption solution. Use a pipette to take 1.50ml of formaldehyde absorbent solution and inject it into the bottom of the plastic formaldehyde absorption box, then place it in an oven with a constant temperature of 100°C, take it out after 13 minutes, and make the formaldehyde absorbent form a film (thickness 1-2um) in the absorption box At the bottom of the box, cover the upper cover of the plastic formaldehyde absorption box and store it at room temperature.

[0014] When using, first place the plastic absorption box at any horizontal position in the room to be tested, open the plastic sealing cover, inject 1.50ml of aqueous solution, stir gently for 5 seconds to dissolve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com