Polymer-based composite structure diffuse reflection material

A polymer-based, composite structure technology, applied in the direction of diffusion elements, etc., can solve the problems of inability to produce lighting effects and low diffuse reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

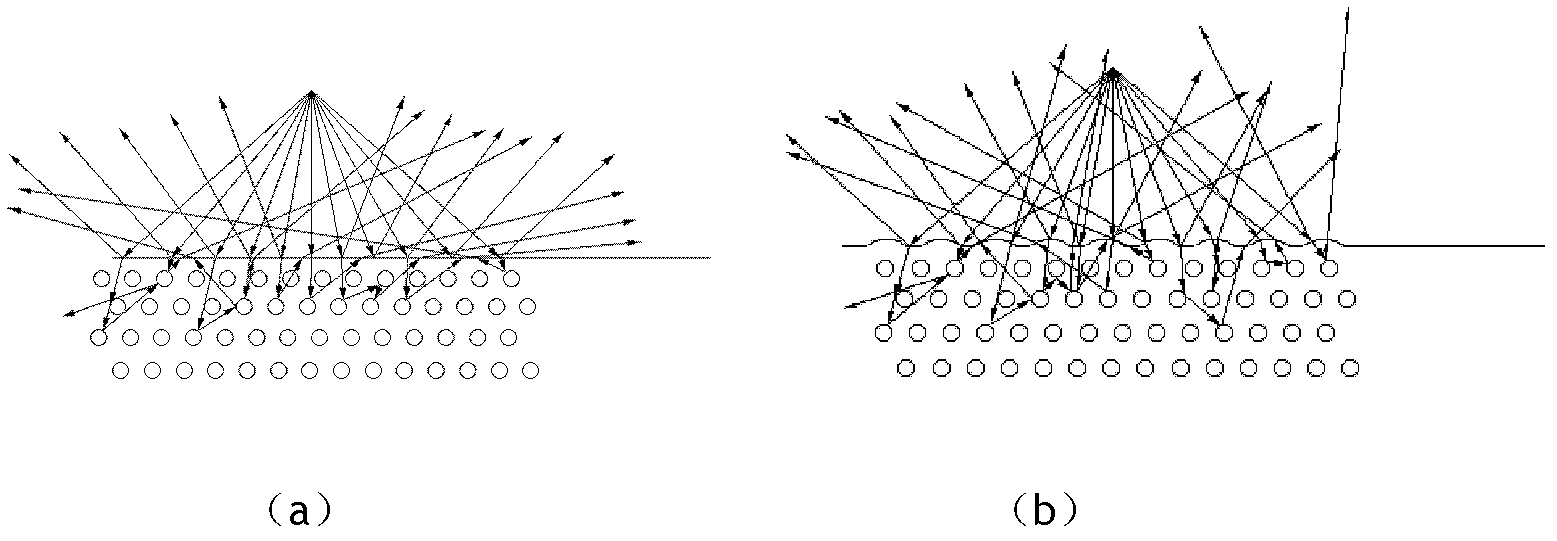

Problems solved by technology

Method used

Image

Examples

Embodiment 1

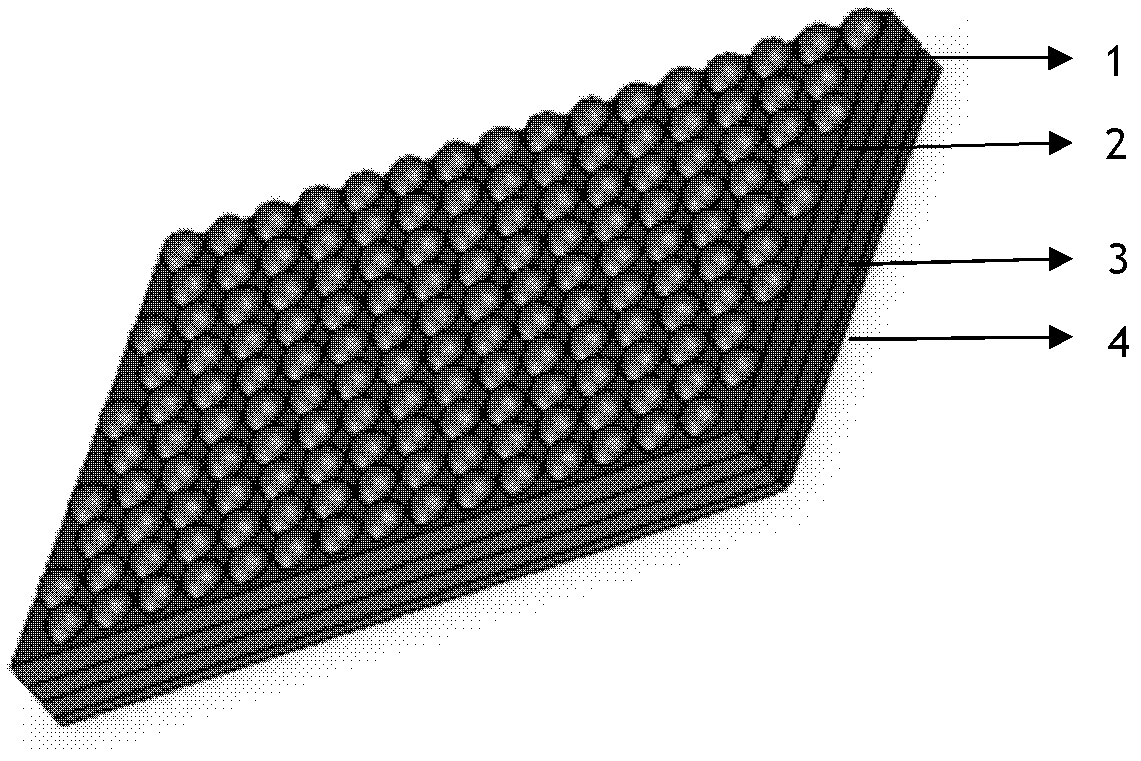

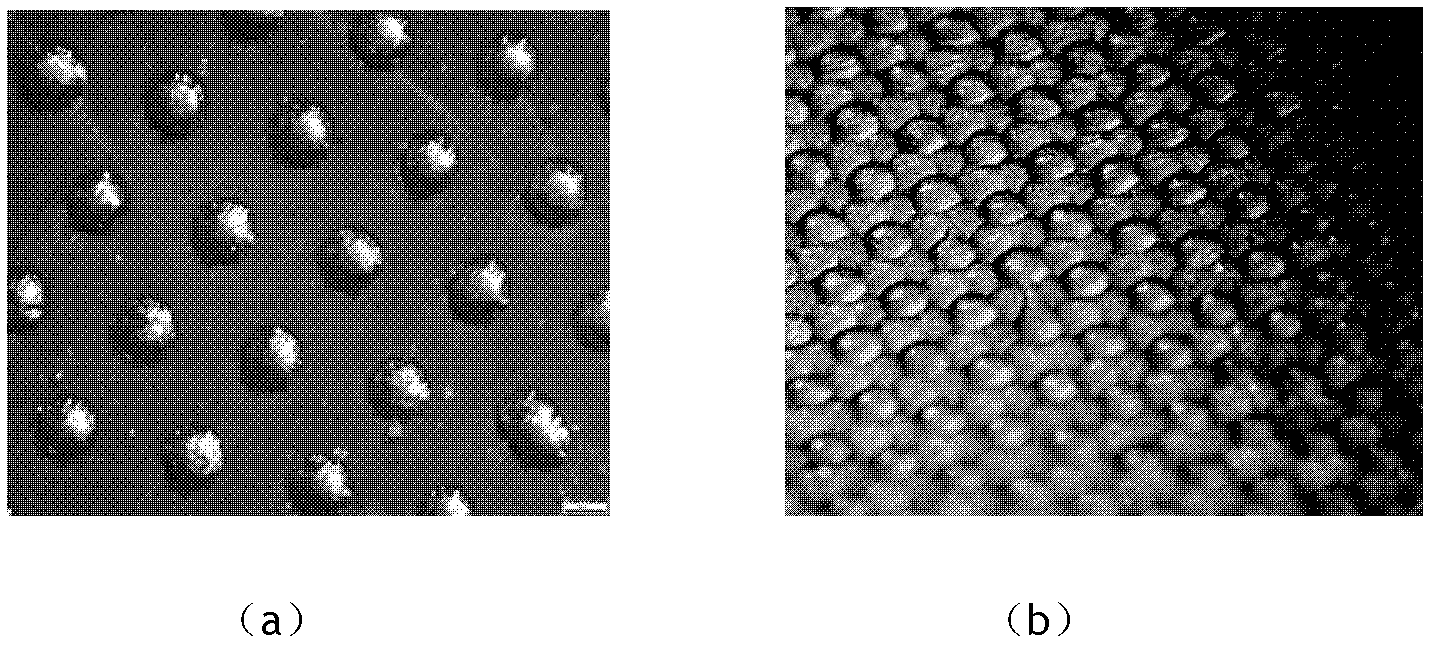

[0038] Example 1, using the method of co-extrusion micro-imprinting to prepare a composite structure diffuse reflective polymer material, a brief introduction of a polypropylene PP and polyethylene terephthalate PET polymer material with a hemispherical microstructure Preparation of Composite Structures. In the first step, the temperature of the two single-screw extruders is raised separately. The temperature of the first heating zone of the first single-screw extruder is set at 190°C, the temperature of the second heating zone is set at 200°C, and the temperature of the third heating zone is set at Set at 200°C, and set the temperature of the sheet die head at 205°C. For the second single-screw extruder, the temperature of the first heating zone is set at 245°C, the temperature of the second heating zone is set at 250°C, the temperature of the third heating zone is set at 250°C, and the temperature of the sheet die head is set at 260°C. In the second step, when the temperatu...

Embodiment 2

[0039]Example 2 Prepare a composite structure diffuse reflective polymer material by coating, select polypropylene PP as the surface material, the first step is to prepare a surface unit with a microstructure, the specific method is to use an extruder to produce a PP sheet, The temperature of the first heating zone of the single-screw extruder is set at 190°C, the temperature of the second heating zone is set at 200°C, the temperature of the third heating zone is set at 200°C, and the temperature of the sheet die head is set at 205°C. When the temperature of the extruder rises to the set value, the prepared polypropylene PP is added to the screw extruder to extrude the sheet, and the sheet is embossed on the twin rollers with microstructure. At this time, the number of revolutions of the double rollers is set at 100-200r / min, which is more appropriate, so that the surface material with microstructure can be prepared. In the second step, the prepared surface unit is coated with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com