P-type heavily-doped silicon carbide film extension preparation method

A technology of silicon carbide and heavy doping, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of satisfying heavy doping of devices, high doping concentration, and improving device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

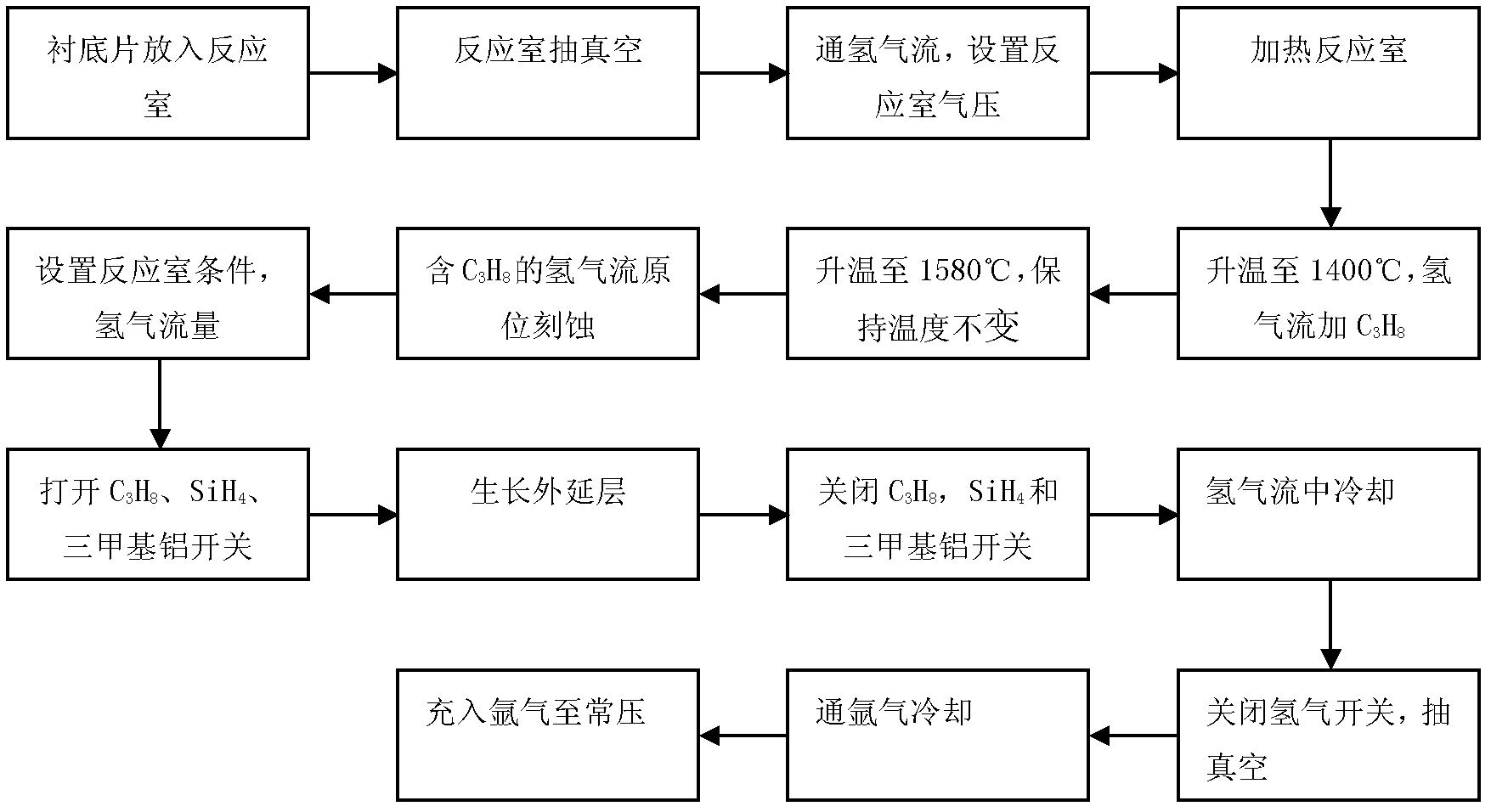

Embodiment 1

[0034] Step 1, placing the silicon carbide substrate into the reaction chamber of the silicon carbide CVD equipment.

[0035] (1.1) Selection bias A 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment;

[0036] (1.2) Vacuumize the reaction chamber until the pressure in the reaction chamber is lower than 1×10 -7 mbar.

[0037] Step 2, heating the reaction chamber in the hydrogen flow.

[0038] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 20L / min;

[0039] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure in the reaction chamber at 100mbar;

[0040] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reaction chamber.

[0041] Step 3, performing in-situ etching on the substrate.

[0042] (3.1) When the reaction chamber temperature...

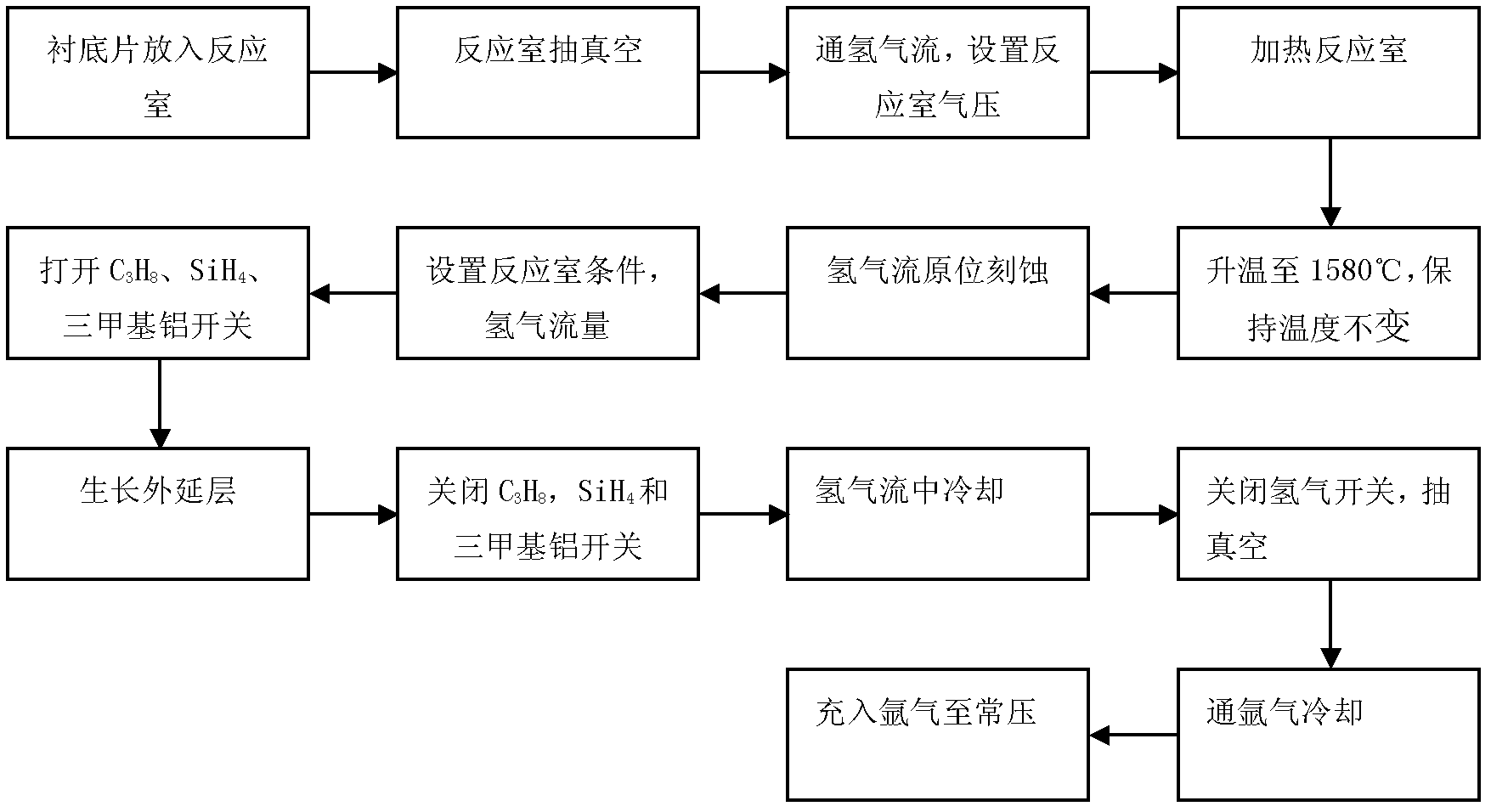

Embodiment 2

[0057] Step 1, select the direction The 4H silicon carbide substrate with a crystal orientation of 8° is placed in the reaction chamber of the silicon carbide CVD equipment; the reaction chamber is evacuated until the pressure of the reaction chamber is lower than 1×10 -7 mbar.

[0058] Step 2, turn on the hydrogen switch leading to the reaction chamber, control the hydrogen flow to gradually increase to 20L / min, and at the same time turn on the vacuum pump to extract the gas in the reaction chamber, keeping the pressure of the reaction chamber at 100mbar; gradually increase the power of the heating source to make the reaction chamber temperature Slowly increase, when the temperature of the reaction chamber is higher than 1400°C, add C with a flow rate of 7mL / min in the hydrogen flow 3 h 8 .

[0059] Step 3, when the temperature of the reaction chamber reaches 1580°C, keep the temperature of the reaction chamber constant, continue to feed hydrogen gas with a flow rate of 2...

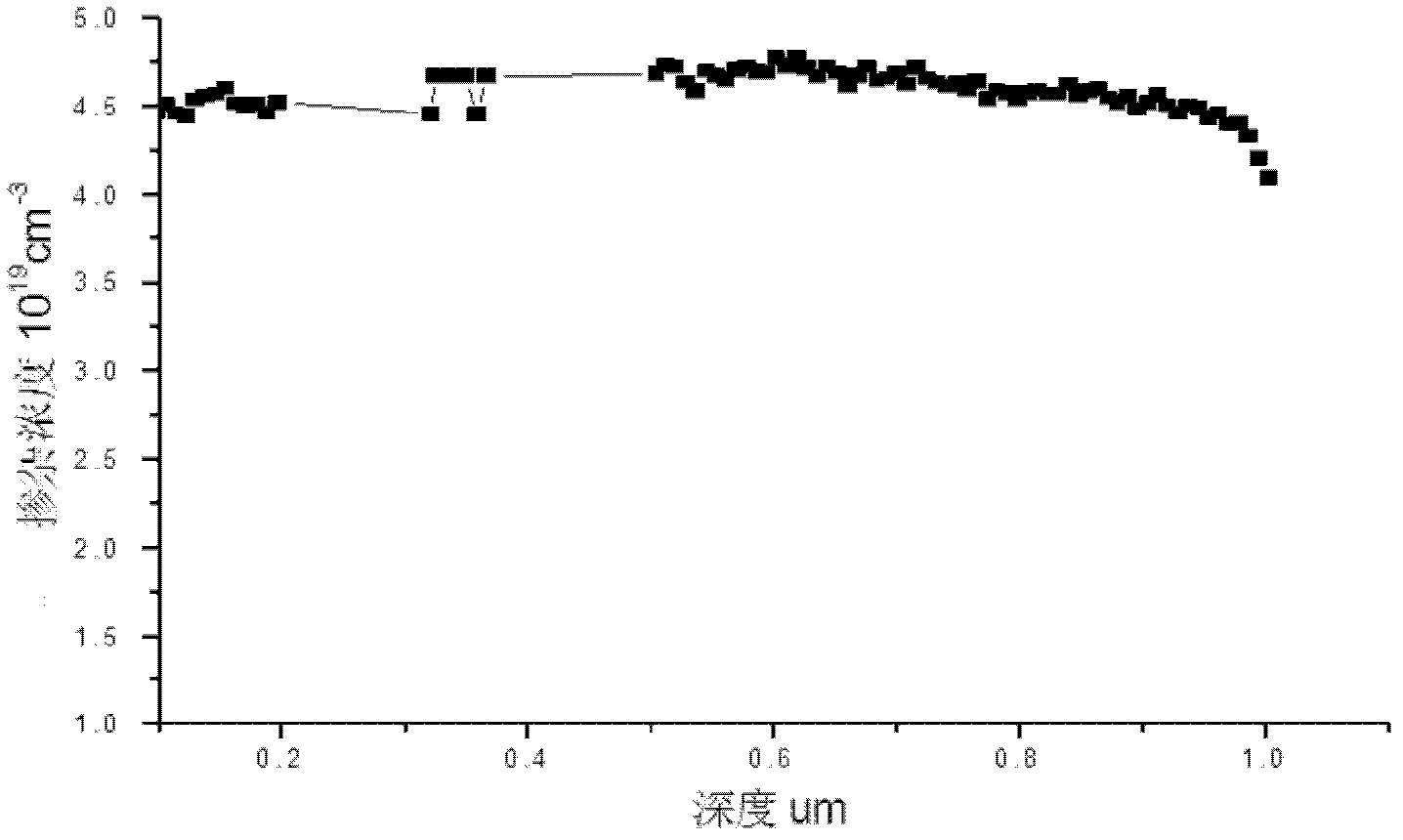

Embodiment 3

[0064] In the first step, the silicon carbide substrate is placed in the reaction chamber of the silicon carbide CVD equipment.

[0065] (1.1) Selection bias A 4H silicon carbide substrate with a crystal orientation of 4° is placed in the reaction chamber of the silicon carbide CVD equipment;

[0066] (1.2) Vacuumize the reaction chamber until the pressure in the reaction chamber is lower than 1×10 -7 mbar.

[0067] In the second step, the reaction chamber is heated in a hydrogen flow.

[0068] (2.1) Open the hydrogen switch leading to the reaction chamber, and control the hydrogen flow to gradually increase to 20L / min;

[0069] (2.2) Turn on the vacuum pump to extract the gas in the reaction chamber, and keep the pressure in the reaction chamber at 100mbar;

[0070] (2.3) Gradually increase the power of the heating source to slowly increase the temperature of the reaction chamber. When the temperature of the reaction chamber is higher than 1400°C, add C with a flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com