Green light emitting glass used for ultraviolet LED and preparation method thereof

A technology of luminescent glass and green light, which is applied in the field of green luminescent glass for ultraviolet LEDs and its preparation, can solve the problems of high production cost of light-emitting devices, unstable phosphor emission, and easy aging, and achieve good chemical stability and thermal stability. Stability, good light transmission, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

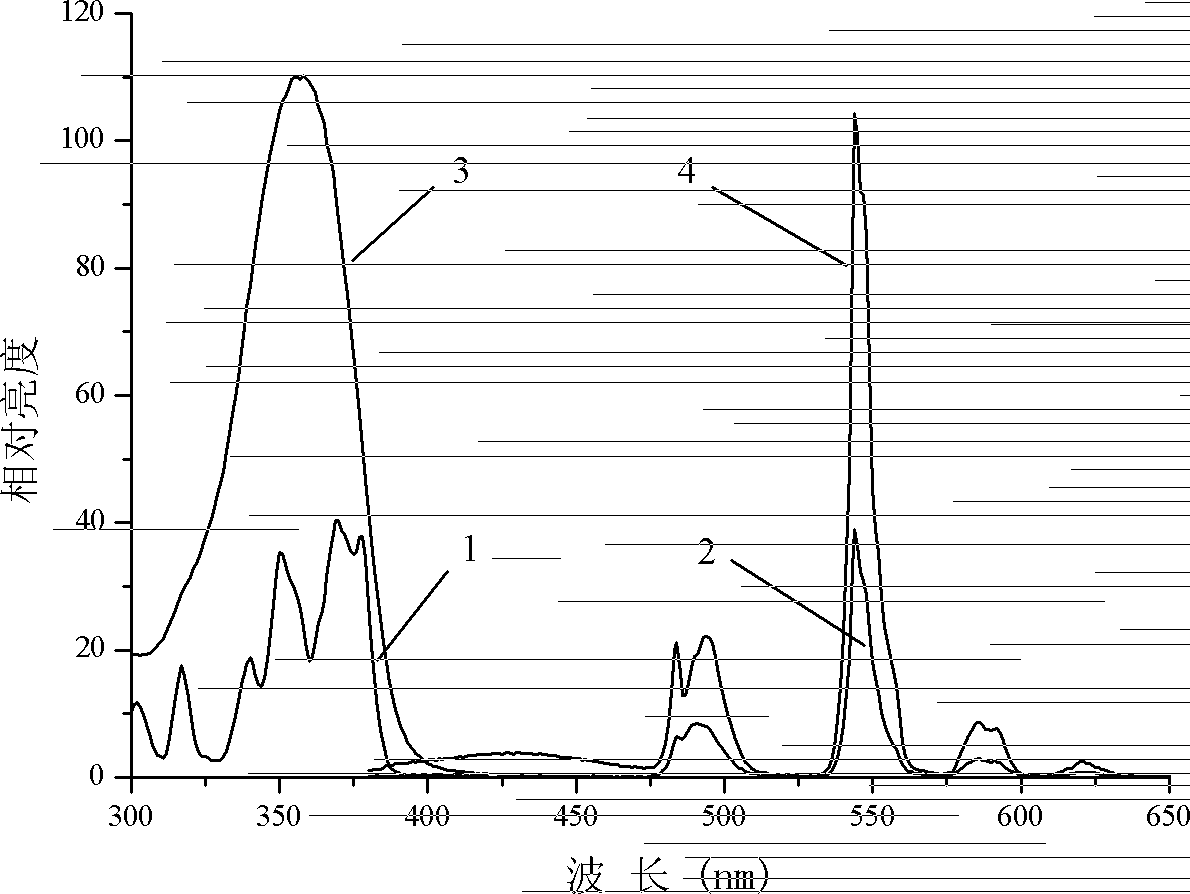

[0025] Embodiment 1, green light-emitting glass 55CaO·20Al for ultraviolet LED 2 o 3 25SiO2 2 0.01Tb 2 o 3

[0026] Preparation method: weigh analytically pure calcium carbonate (CaCO 3 ) 16.6g, alumina (Al 2 o 3 )6.15g, silicon dioxide (SiO 2 )4.53g and terbium oxide (Tb 4 o 7 ) 0.01g, put the weighed raw materials into a platinum crucible after grinding and mixing them evenly in a mortar, then put the platinum crucible with the raw materials into a high-temperature box furnace, melt the glass at 1700°C for 1 hour The melt is poured into a cast iron mold, pressed into a transparent glass, and then the transparent glass is placed in an annealing furnace at 95% N 2 +5%H 2 (Volume percentage, the same below) is heated to 650°C in a reducing atmosphere, kept for 20 hours and then cooled to room temperature to prepare 55CaO·20Al 2 o 3 25SiO2 2 0.01Tb 2 o 3 Glowing glass that emits green light.

Embodiment 2

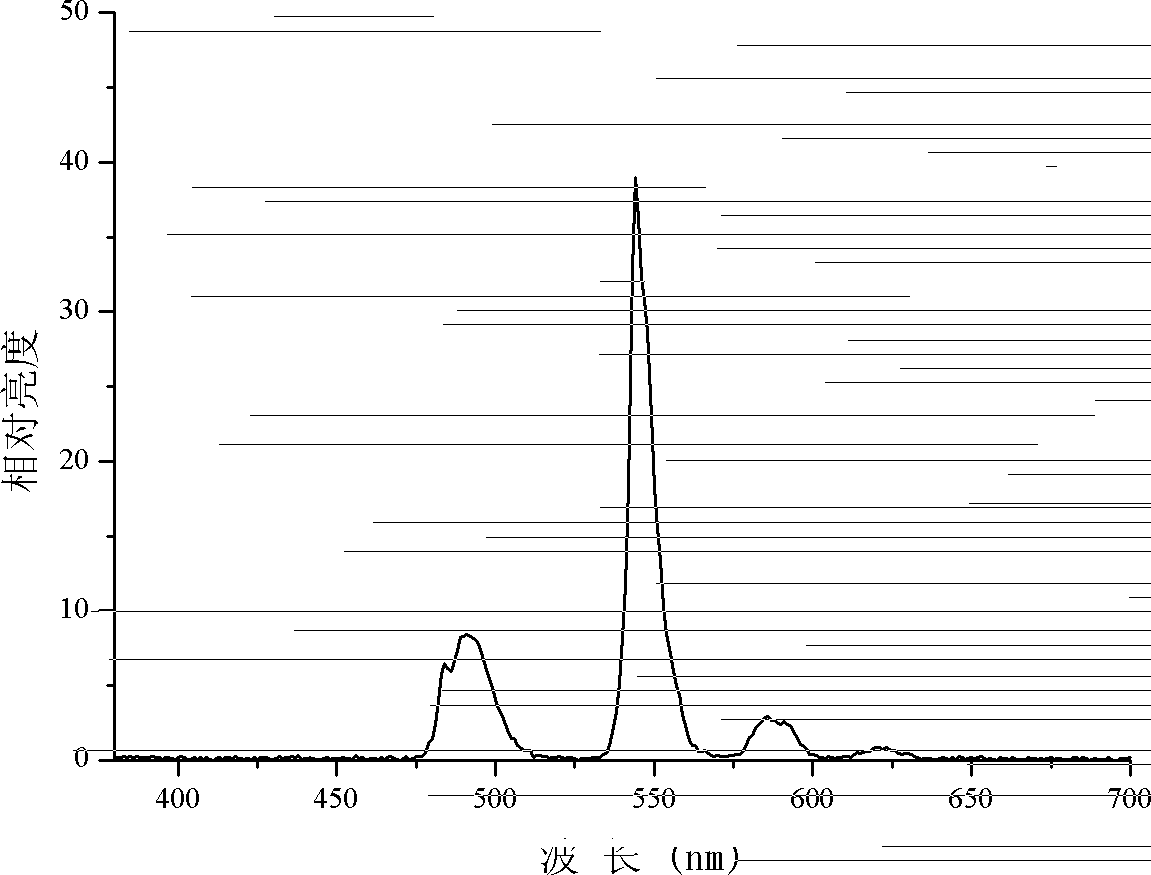

[0027] Example 2, green light-emitting glass 48CaO·17Al for ultraviolet LED 2 o 3 25SiO2 2 10Tb 2 o 3

[0028] Preparation method: weigh analytically pure calcium carbonate (CaCO 3 ) 10.02g, alumina (Al 2 o 3 ) 3.61g, silicon dioxide (SiO 2 )3.13g and terbium oxide (Tb 4 o 7 ) 7.79g, put the weighed raw materials into a corundum crucible after grinding and mixing them evenly in a mortar, then put the corundum crucible with the raw materials into a high-temperature box furnace, melt the glass at 1650°C for 0.5 hours The melt is poured into a cast iron mold, pressed into a transparent glass, and then the transparent glass is placed in an annealing furnace at 95% N 2 +5%H 2 48CaO·17Al can be prepared by raising the temperature to 950°C in a reducing atmosphere, keeping it warm for 3 hours and then cooling to room temperature. 2 o 3 25SiO2 2 10Tb 2 o 3 Glowing glass that emits green light. Such as figure 2 Shown is the emission spectrum of the luminescent glass ...

Embodiment 3

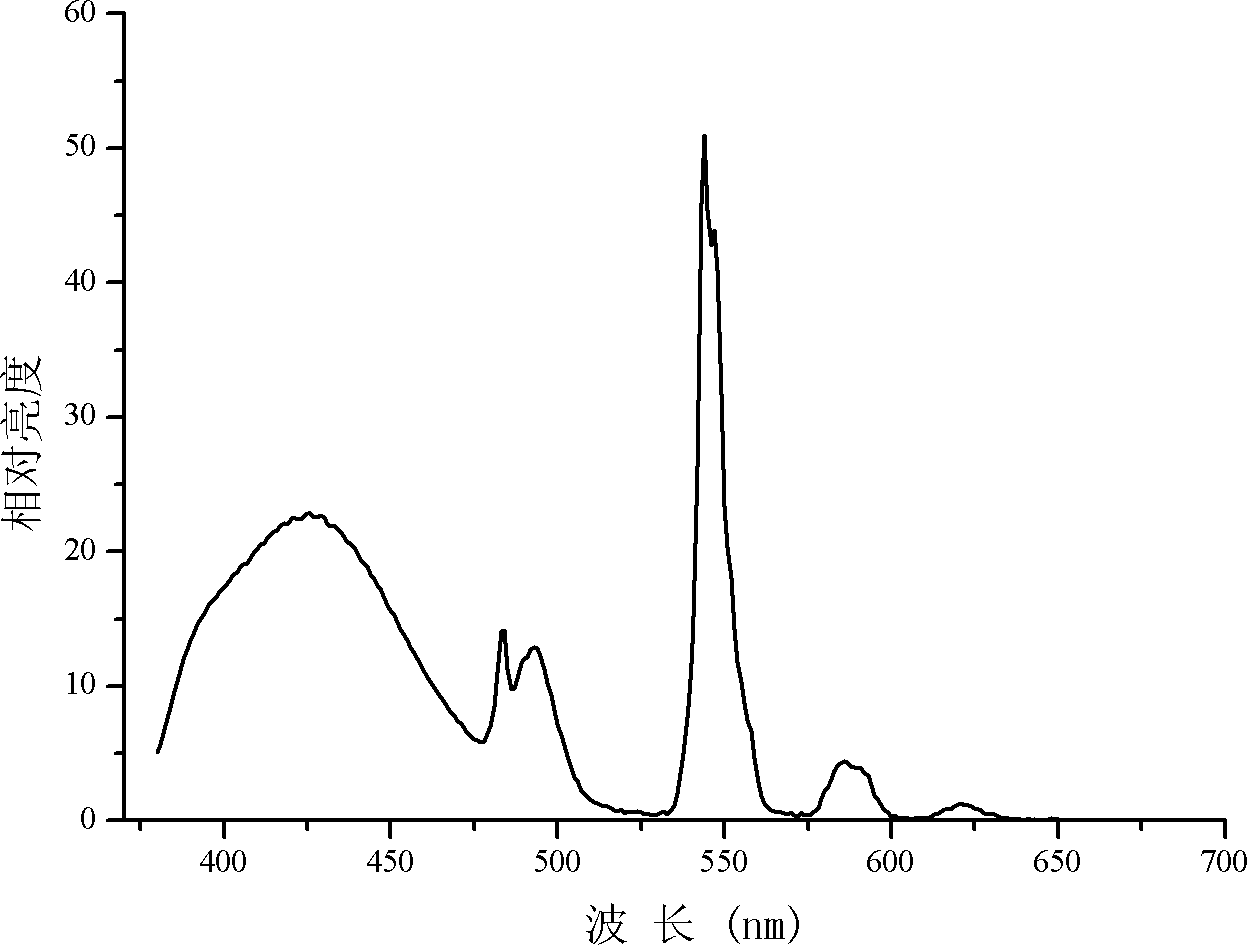

[0029] Example 3, green light-emitting glass 50CaO·20Al for ultraviolet LED 2 o 3 28SiO2 2 0.5CeO 2 1.0Tb 2 o 3

[0030] Preparation method: weigh analytically pure calcium carbonate (CaCO 3 ) 14.34g, alumina (Al 2 o 3)5.84g, silicon dioxide (SiO 2 )4.82g, cerium oxide (CeO 2 )0.24g and terbium oxide (Tb 4 o 7 ) 1.07g, grind and mix the weighed raw materials evenly in a mortar, put them into a corundum crucible, then put the corundum crucible with raw materials into a high-temperature box furnace, and melt it at 1650°C for 1 hour. The glass melt is poured onto cast iron molds and pressed into clear glass. Then put the transparent glass in the annealing furnace, 95%N 2 +5%H 2 50CaO·20Al can be prepared by raising the temperature to 900°C in a reducing atmosphere, keeping it warm for 5 hours and then cooling to room temperature. 2 o 3 28SiO2 2 0.5CeO 2 1Tb 2 o 3 Glowing glass that emits green light. Such as image 3 Shown is the emission spectrum of the lum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com