Light-emitting device and preparation method thereof

A technology for light-emitting devices and light-emitting layers, which can be used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., and can solve problems such as low luminous efficiency of devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Correspondingly, a method for preparing a light-emitting device includes the following steps of preparing a composite material layer:

[0046] S01. Depositing the composite material on the substrate to form a composite material layer;

[0047] Wherein, the composite material includes: titanium dioxide nanoparticles and a ligand as shown in formula I, and the ligand is connected to the titanium dioxide nanoparticles by a sulfur anion;

[0048]

[0049] Wherein, n is an integer between 0 and 8.

[0050] In the method for preparing a light-emitting device provided in the embodiments of the present invention, a composite material is deposited on a substrate to form a composite material layer, and the material of the composite material layer includes: titanium dioxide nanoparticles and a ligand as shown in formula I, and the ligand is composed of sulfide anion and Titanium dioxide nanoparticle connections. The ligand shown in formula I has sulfur anion, amino group and ...

Embodiment approach

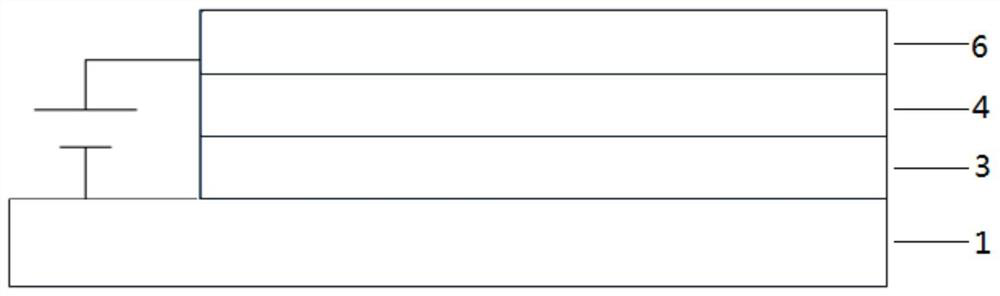

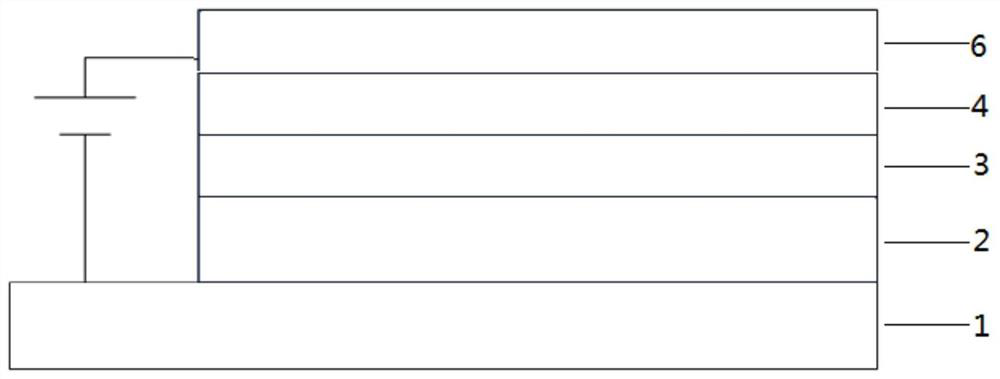

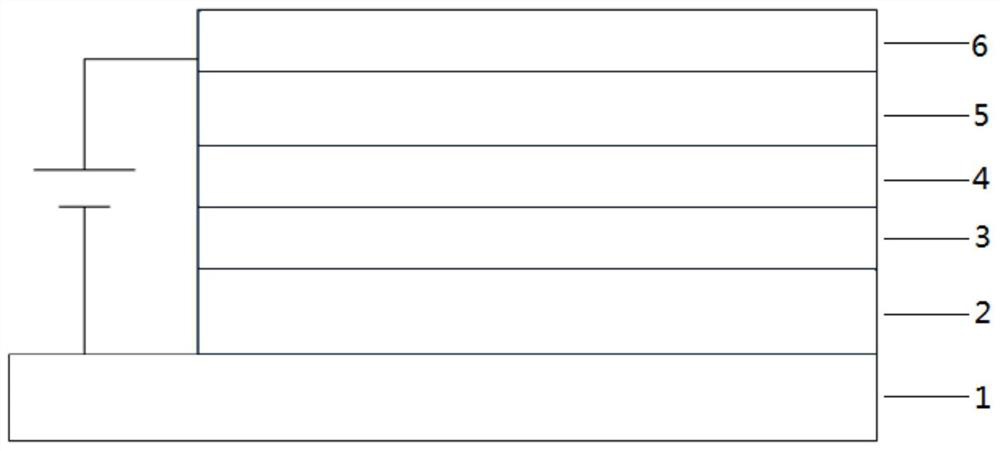

[0066] As an implementation manner, the matrix includes: a second electrode, a titanium dioxide layer is formed on the second electrode, and the composite material is formed on the titanium dioxide layer. In some embodiments, the light-emitting device uses the second electrode as the bottom electrode, and the matrix includes: the second electrode, and a titanium dioxide layer is formed on the second electrode. In some embodiments, the second electrode is ITO conductive glass. Before being used to prepare the light-emitting device, the ITO conductive glass is pre-treated, including: first cleaning the ITO, dipping a small amount of soapy water with a cotton swab to wipe the surface of the ITO to remove impurities visible to the naked eye on the surface, and then using deionized water , acetone, ethanol, and isopropanol for ultrasonic cleaning for 15 minutes, and then blow dry with nitrogen for use.

[0067] In addition to the above step of preparing the composite material laye...

Embodiment 1

[0070] In this embodiment, a light-emitting device is prepared, which specifically includes the following steps:

[0071] First, clean the ITO. Wipe the surface of the ITO with a cotton swab dipped in a small amount of soapy water to remove visible impurities on the surface, then ultrasonically clean it with deionized water, acetone, ethanol, and isopropanol for 15 minutes, and then dry it with nitrogen gas for use.

[0072] Next, prepare 200 mL of ice-water mixture, add 0.1 mol of TiCl 4 Add it, and the adding process should be slow to prevent its hydrolysis too fast; then prepare 10mL of methionine ethanol solution, and its concentration is controlled at 200 moles per liter; then, slowly drop the methionine ethanol solution into TiCl previously prepared 4 In the solution, stir while adding it dropwise. After stirring evenly, pour the solution into the hydrothermal reaction kettle, and slowly put the previously cleaned ITO glass into the hydrothermal reaction kettle, with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com