Aqueous aluminum base solder paste

A brazing-based, water-based technology, applied in the direction of welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of poor environmental performance and storage difficulties of aluminum-based brazing paste, and achieve easy cleaning, easy storage, strong The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

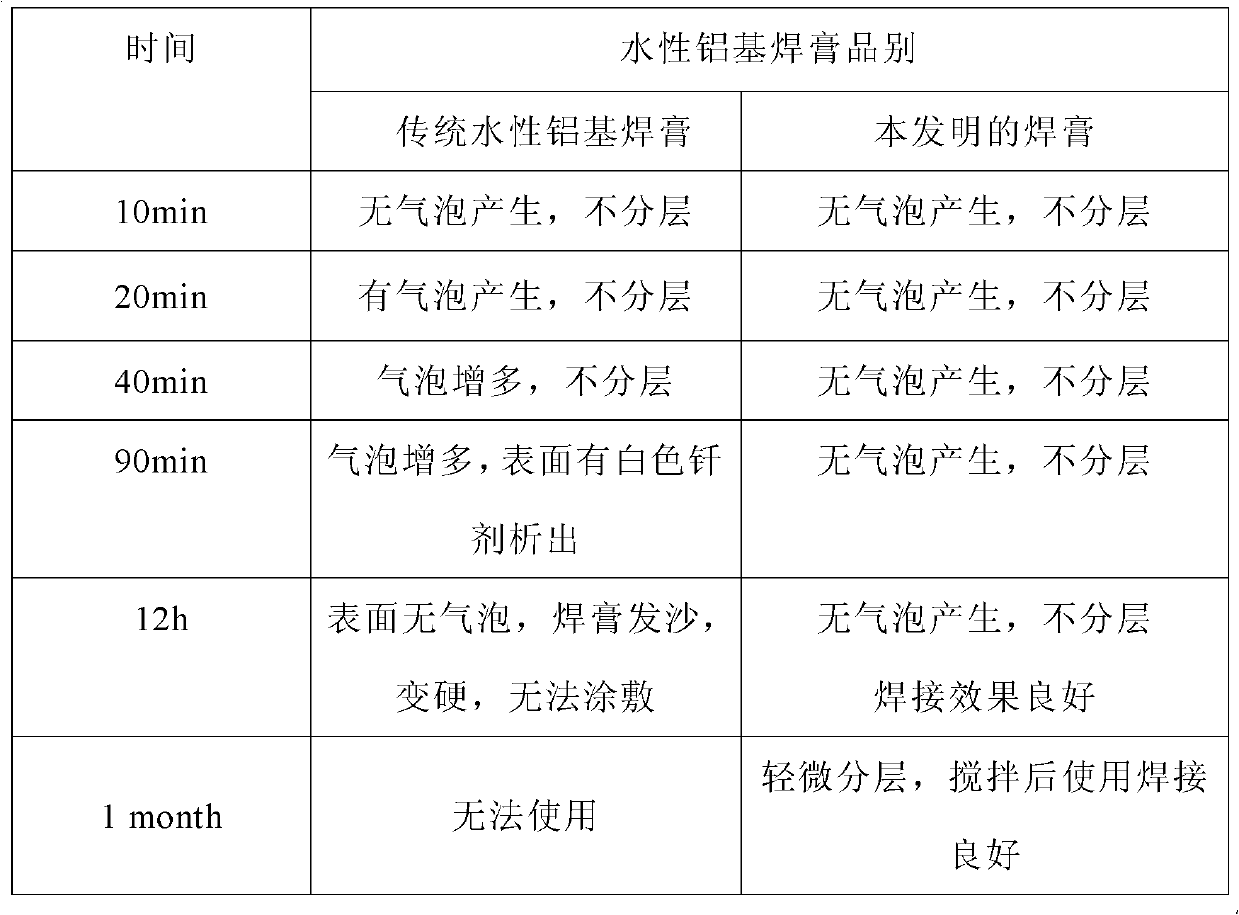

Examples

Embodiment 1

[0017] A water-based aluminum-based brazing paste is composed of the following components: aluminum alloy brazing powder accounting for 65% of the total weight of the water-based aluminum-based brazing paste, and the aluminum alloy is composed of: Al 90%, Si 10% ; Account for the soldering flux of 20% of the total weight of the solder paste, the weight percentage of the soldering flux is composed of: AlF 3 54%, KF 46%; account for the paste body of 15% of the total weight of the solder paste, the weight percentage of the paste body is composed of: sodium carboxymethyl cellulose 1%, hydroxyethyl cellulose 1%, polyoxygen Ethylene 3%, water 20%, formamide 70%, propylene glycol 5%.

Embodiment 2

[0019] The solder paste of this example is composed of: aluminum alloy base solder powder accounting for 30% of the total weight of the solder paste, and the weight percentage of the aluminum alloy is composed of: Al 88%, Si12%; accounting for 30% of the total weight of the solder paste, its weight The percentages are grouped into: AlF 3 43.2%, KF 36.8%, NaF 15%, KCl 5%; accounting for 40% of the total weight of the solder paste, its weight percentage is composed of: ethyl cellulose 10%, polyvinylpyrrolidone 5%, N, N- Dimethylformamide 40%, N-methylpyrrolidone 25%, ethylene glycol 20%.

Embodiment 3

[0021] The solder paste of this example is composed of: aluminum alloy-based solder powder accounting for 60% of the total weight of the solder paste, and the weight percentage of the aluminum alloy is: Al 62%, Si10%, Cu 28%; accounting for 10% of the total weight of the solder paste Soldering flux, its weight percentage composition: AlF3 48.5%, KF 41.5%, CsF 10%; Accounting for the paste body of 30% of the total weight of solder paste, its weight percentage composition is: hydroxypropyl cellulose 1%, polyethylene oxide 1 %, water 13%, formamide 30%, dimethylformamide 60%, ethanol 5%, glycerol 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com