Preparation method of CuO micro-/nano-array electrode for lithium ion battery

A lithium-ion battery and array electrode technology, which is applied in the nanomaterial preparation technology and energy fields, can solve the problems of poor cycle performance and rate performance of CuO, achieve good electrochemical performance, simple preparation procedures, and relieve volume change and stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

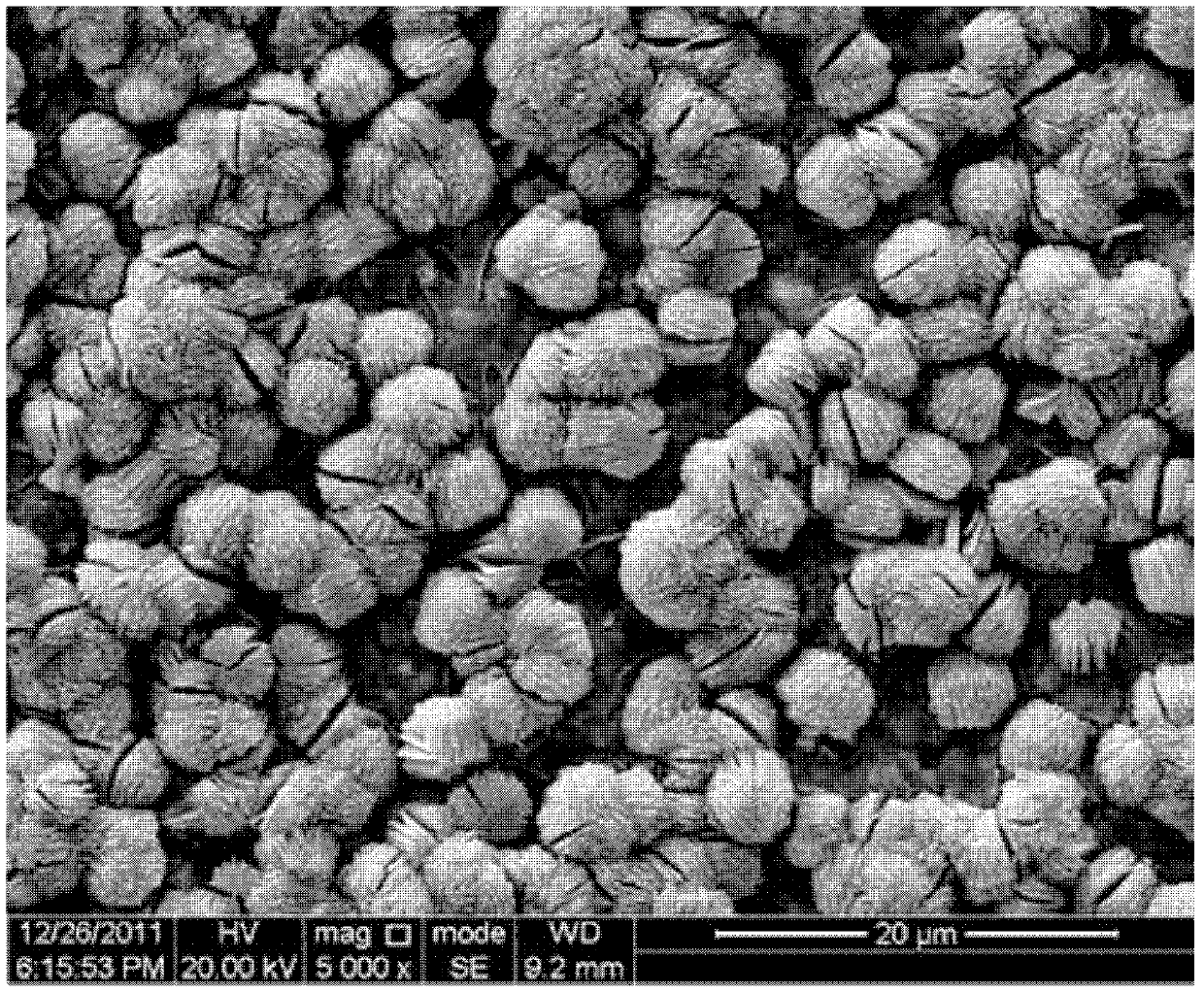

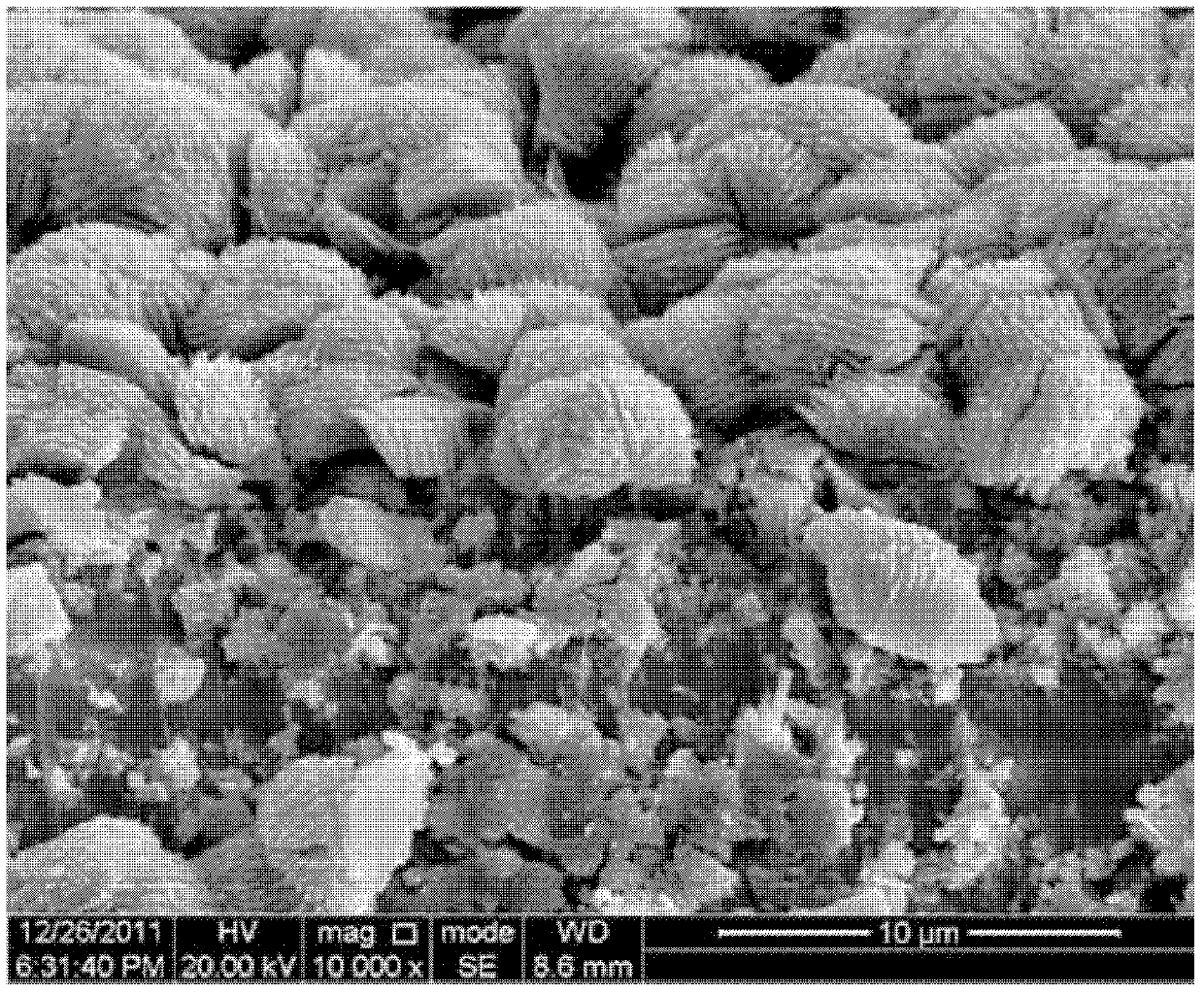

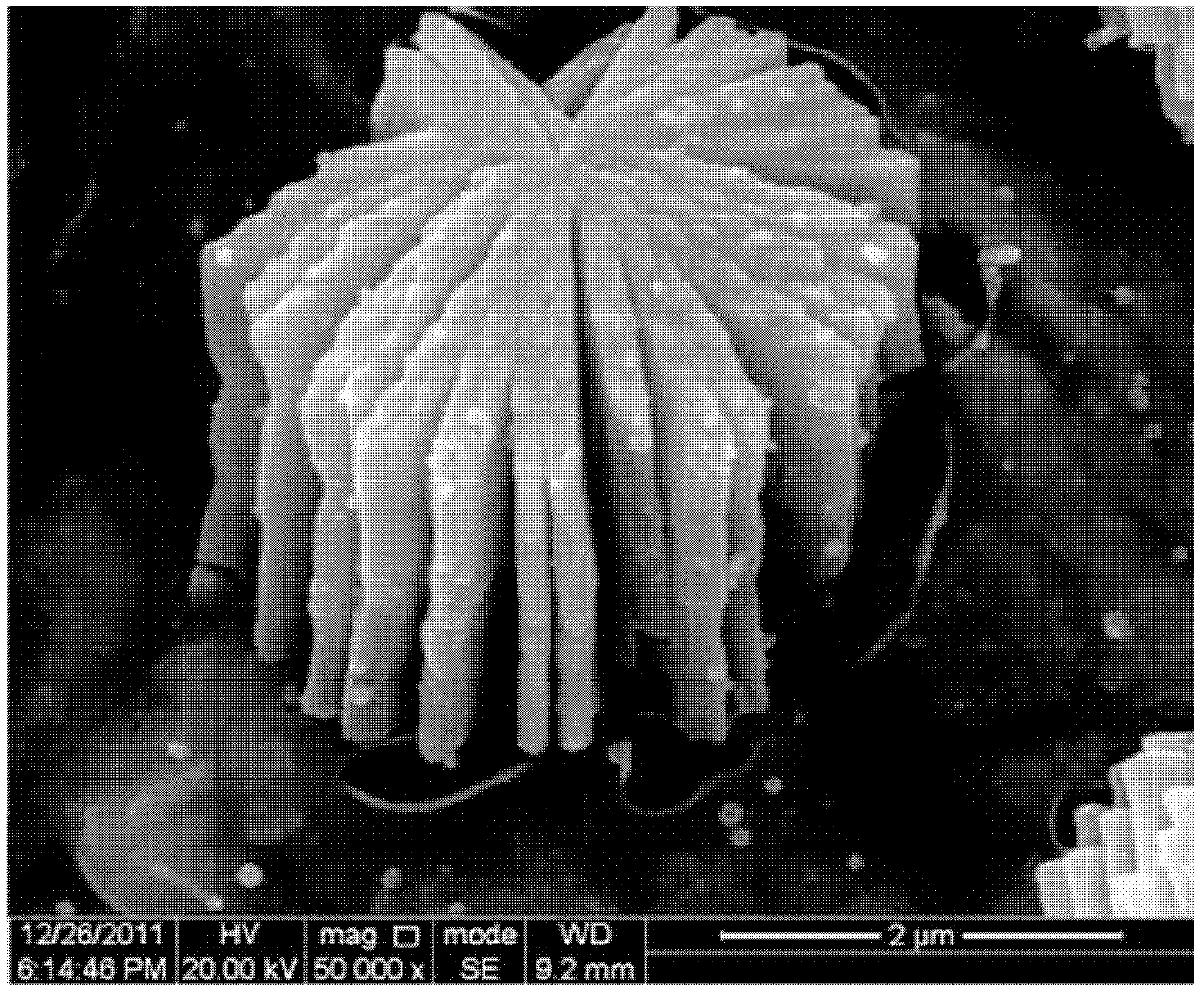

[0027] Specific implementation mode 1: The preparation method of the lithium-ion battery micro / nano CuO array electrode in this embodiment is as follows:

[0028] 1. Cover the copper foil 1cm~3cm above the ammonia solution, and then grow it at 5℃~40℃ for 2h~12h to obtain Cu(OH) 2 micro / nano gear arrays;

[0029] Second, the Cu(OH)2 The micro / nano gear array is placed in an inert atmosphere, raised to 120°C at a rate of 2°C / min to 5°C / min, kept at 120°C for 2 hours, and then raised at a rate of 2°C / min to 5°C / min to 180°C, and kept at 180°C for 2 hours, and then naturally cooled to room temperature to obtain a CuO micro / nano gear array electrode; the ammonia solution described in step 1 is composed of concentrated ammonia water and water in a volume ratio of 1:1-6 .

[0030] The copper foil used in this embodiment is produced by Kingboard Copper Foil Group Co., Ltd.

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass concentration of the concentrated ammonia water is 25%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the inert atmosphere described in step two is N 2 Atmosphere or Ar 2 atmosphere. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com